Search

- Page Path

- HOME > Search

- Effects of 3 different light-curing units on the physico-mechanical properties of bleach-shade resin composites

- Azin Farzad, Shahin Kasraei, Sahebeh Haghi, Mahboubeh Masoumbeigi, Hassan Torabzadeh, Narges Panahandeh

- Restor Dent Endod 2022;47(1):e9. Published online February 7, 2022

- DOI: https://doi.org/10.5395/rde.2022.47.e9

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

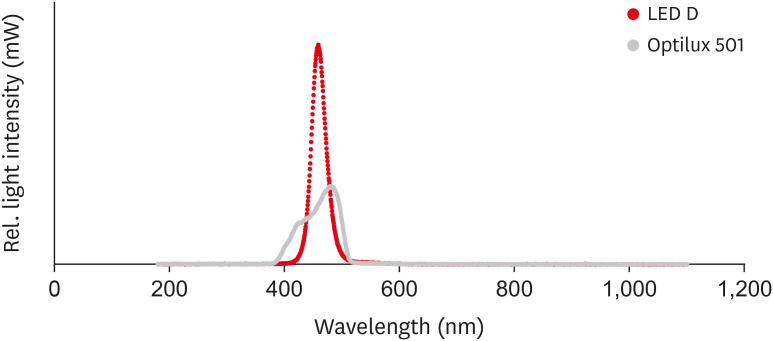

ePub Objectives This study investigated the microhardness, flexural strength, and color stability of bleach-shade resin composites cured with 3 different light-curing units.

Materials and Methods In this

in vitro experimental study, 270 samples were fabricated of bleach and A2 shades of 3 commercial resin composites (Point 4, G-aenial Anterior, and Estelite Sigma Quick). Samples (n = 5 for each trial) were cured with Bluephase N, Woodpecker LED.D, and Optilux 501 units and underwent Vickers microhardness and flexural strength tests. The samples were tested after 24 hours of storage in distilled water. Color was assessed using a spectrophotometer immediately after preparation and 24 hours after curing. Data were analyzed using 3-way analysis of variance and the Tukey test (p ≤ 0.001).Results Samples cured with Optilux exhibited the highest and those cured with LED.D exhibited the lowest microhardness (

p = 0.023). The bleach shade of Point 4 composite cured with Optilux displayed the highest flexural strength, while the same composite and shade cured with Sigma Quick exhibited the lowest (p ≤ 0.001). The color change after 24 hours was greatest for the bleach shade of G-aenial cured with Bluephase N and least for the A2 shade of Sigma Quick cured with Optilux (p ≤ 0.001).Conclusions Light curing with polywave light-emitting diode (LED) yielded results between or statistically similar to those of quartz-tungsten-halogen and monowave LED in the microhardness and flexural strength of both A2 and bleach shades of resin composites. However, the brands of light-curing devices showed significant differences in color stability.

-

Citations

Citations to this article as recorded by- Mechanical Behaviour of Novel Nanohybrid Resin Composite Using Two Light Cure Systems

Ghada H. Naguib, Jumana Mazhar, Abeer Alnowaiser, Abdulghani Mira, Hisham Mously, Rabab Aljawi, Samar H. Abuzinadah, Mohamed T. Hamed

International Dental Journal.2025; 75(2): 1136. CrossRef - Repair Bond Strength of Aged Composite: Effect of Thermocycling and Surface Treatment

Sina Yarmoradian, Ladan Ranjbar Omrani, Elham Ahmadi, Niyousha Rafeie, Mahdi Abbasi, Nastaran Dabiri Shahabi

Journal of Research in Dental and Maxillofacial Sciences.2025; 10(3): 228. CrossRef - Evaluation of the Depth of Cure by Microhardness of Bulk-Fill Composites with Monowave and Polywave LED Light-Curing Units

Socratis Thomaidis, Dimitris Kampouropoulos, Maria Antoniadou, Afrodite Kakaboura

Applied Sciences.2024; 14(24): 11532. CrossRef - Effect of hard segment chemistry and structure on the self‐healing properties of UV‐curable coatings based on the urethane acrylates with built‐in Diels–Alder adduct

Paulina Bednarczyk, Karolina Mozelewska, Małgorzata Nowak, Joanna Klebeko, Joanna Rokicka, Paula Ossowicz‐Rupniewska

Journal of Applied Polymer Science.2023;[Epub] CrossRef - Effects of Dental Bleaching Agents on the Surface Roughness of Dental Restoration Materials

Alexandru Dan Popescu, Mihaela Jana Tuculina, Oana Andreea Diaconu, Lelia Mihaela Gheorghiță, Claudiu Nicolicescu, Cristian Niky Cumpătă, Cristiana Petcu, Jaqueline Abdul-Razzak, Ana Maria Rîcă, Ruxandra Voinea-Georgescu

Medicina.2023; 59(6): 1067. CrossRef - Effect of Polywave and Monowave Light Curing Units on Color Change of Composites Containing Trime-thylbenzoyl-Diphenyl-Phosphine Before and After Aging

Negar Madihi, Maryam Hoorizad ganjkar, Negin Nasoohi, Ali Kaboudanian Ardestani

Journal of Research in Dental and Maxillofacial Sciences.2023; 8(4): 249. CrossRef

- Mechanical Behaviour of Novel Nanohybrid Resin Composite Using Two Light Cure Systems

- 2,214 View

- 35 Download

- 4 Web of Science

- 6 Crossref

- Physicochemical characterization of two bulk fill composites at different depths

- Guillermo Grazioli, Carlos Enrique Cuevas-Suárez, Leina Nakanishi, Alejandro Francia, Rafael Ratto de Moraes

- Restor Dent Endod 2021;46(3):e39. Published online July 5, 2021

- DOI: https://doi.org/10.5395/rde.2021.46.e39

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

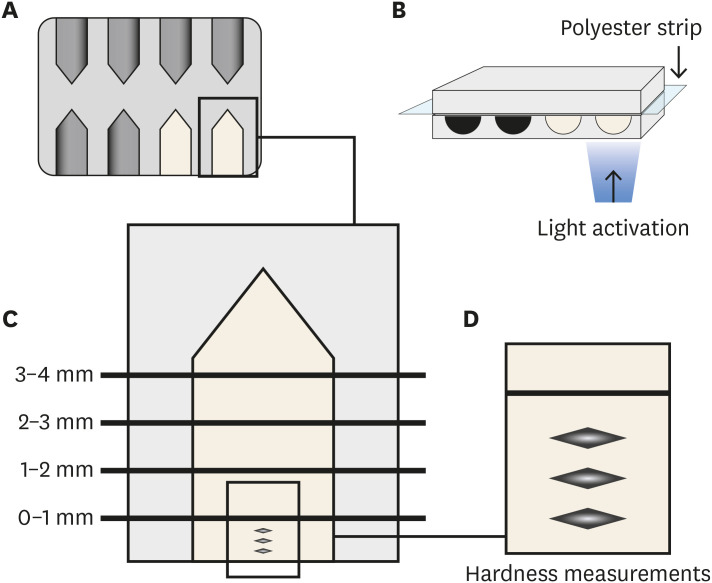

ePub Objectives This study analyzed the physical-chemical behavior of 2 bulk fill resin composites (BFCs; Filtek Bulk Fill [FBF], and Tetric-N-Ceram Bulk Fill [TBF]) used in 2- and 4-mm increments and compared them with a conventional resin composite (Filtek Z250).

Materials and Methods Flexural strength and elastic modulus were evaluated by using a 3-point bending test. Knoop hardness was measured at depth areas 0–1, 1–2, 2–3, and 3–4 mm. The translucency parameter was measured using an optical spectrophotometer. Real-time polymerization kinetics was analyzed using Fourier transform infrared spectroscopy.

Results Flexural strength was similar among the materials, while TBF showed lower elastic modulus (Z250: 6.6 ± 1.3, FBF: 6.4 ± 0.9, TBF: 4.3 ± 1.3). The hardness of Z250 was similar only between 0–1 mm and 1–2 mm. Both BFCs had similar hardness until 2–3 mm, and showed significant decreases at 3–4 mm (FBF: 33.45 ± 1.95 at 0–1 mm to 23.19 ± 4.32 at 3–4 mm, TBF: 23.17 ± 2.51 at 0–1 mm to 15.11 ± 1.94 at 3–4 mm). The BFCs showed higher translucency than Z250. The polymerization kinetics of all the materials were similar at 2-mm increments. At 4-mm, only TBF had a similar degree of conversion compared with 2 mm.

Conclusions The BFCs tested had similar performance compared to the conventional composite when used in up to 2-mm increments. When the increment was thicker, the BFCs were properly polymerized only up to 3 mm.

-

Citations

Citations to this article as recorded by- Microhardness According to Surface, Distance and Time of Photopolymerization of a Bulk-Fill Resin: In Vitro Study

María José Loayza-Gallegos, Gino Hernan Vidalón-Romo, Julissa Amparo Dulanto-Vargas

Odovtos - International Journal of Dental Sciences.2026; 1(1): 384. CrossRef - Comparative In Vitro Analysis of Mechanical Properties in Three High-Viscosity Bulk-Fill Composite Resins

Carlos I. Santacruz, Jorge I. Fajardo, César A. Paltán, Ana del Carmen Armas-Vega, Eleonor Vélez León

Journal of Composites Science.2025; 9(11): 623. CrossRef - Translucency of bulk‐fill composite materials: A systematic review

Gaetano Paolone, Sofia Baldani, Niccolò De Masi, Mauro Mandurino, Giacomo Collivasone, Nicola Scotti, Enrico Gherlone, Giuseppe Cantatore

Journal of Esthetic and Restorative Dentistry.2024; 36(7): 995. CrossRef - Can composite packaging and selective enamel etching affect the clinical behavior of bulk-fill composite resin in posterior restorations? 24-month results of a randomized clinical trial

Marcos de Oliveira BARCELEIRO, Chane TARDEM, Elisa Gomes ALBUQUERQUE, Leticia de Souza LOPES, Stella Soares MARINS, Luiz Augusto POUBEL, Roberta BARCELOS, Romina ÑAUPARI-VILLASANTE, Alessandro Dourado LOGUERCIO, Fernanda Signorelli CALAZANS

Journal of Applied Oral Science.2023;[Epub] CrossRef - No-Cap Flowable Bulk-Fill Composite: Physico-Mechanical Assessment

Abdullah Alshehri, Feras Alhalabi, Ali Robaian, Mohammed A. S. Abuelqomsan, Abdulrahman Alshabib, Eman Ismail, Faisal Alzamil, Nawaf Alotaibi, Hamad Algamaiah

Polymers.2023; 15(8): 1847. CrossRef - The Microhardness and Surface Roughness Assessment of Bulk-Fill Resin Composites Treated with and without the Application of an Oxygen-Inhibited Layer and a Polishing System: An In Vitro Study

Ann Carrillo-Marcos, Giuliany Salazar-Correa, Leonor Castro-Ramirez, Marysela Ladera-Castañeda, Carlos López-Gurreonero, Hernán Cachay-Criado, Ana Aliaga-Mariñas, Alberto Cornejo-Pinto, Luis Cervantes-Ganoza, César Félix Cayo-Rojas

Polymers.2022; 14(15): 3053. CrossRef

- Microhardness According to Surface, Distance and Time of Photopolymerization of a Bulk-Fill Resin: In Vitro Study

- 2,216 View

- 20 Download

- 6 Web of Science

- 6 Crossref

- Influence of 10-MDP concentration on the adhesion and physical properties of self-adhesive resin cements

- Kazuhiko Shibuya, Naoko Ohara, Serina Ono, Kumiko Matsuzaki, Masahiro Yoshiyama

- Restor Dent Endod 2019;44(4):e45. Published online November 12, 2019

- DOI: https://doi.org/10.5395/rde.2019.44.e45

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

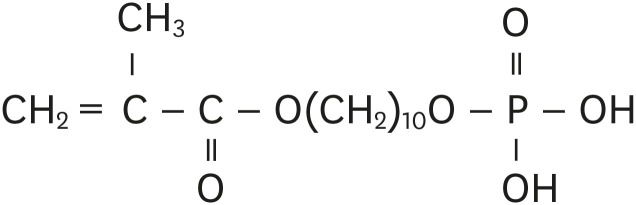

ePub Objectives Self-adhesive resin cements contain functional monomers that enable them to adhere to the tooth structure without a separate adhesive or etchant. One of the most stable functional monomers used for chemical bonding to calcium in hydroxyapatite is 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP). The aim of this study was to evaluate the influence of the10-MDP concentration on the bond strength and physical properties of self-adhesive resin cements.

Materials and Methods We used experimental resin cements containing 3 different concentrations of 10-MDP: 3.3 wt% (RC1), 6.6 wt% (RC2), or 9.9 wt% (RC3). The micro-tensile bond strength of each resin cement to dentin and a hybrid resin block (Estenia C&B, Kuraray Noritake Dental) was measured, and the fractured surface morphology was analyzed. Further, the flexural strength of the resin cements was measured using the three-point bending test. The water sorption and solubility of the cements following 30 days of immersion in water were measured.

Results The bond strength of RC2 was significantly higher than that of RC1. There was no significant difference between the bond strength of RC2 and that of RC3. The water sorption of RC3 was higher than that of any other cement. There were no significant differences in the three-point bending strength or water solubility among all three types of cements.

Conclusions Within the limitations of this study, it is suggested that 6.6 wt% 10-MDP showed superior properties than 3.3 wt% or 9.9 wt% 10-MDP in self-adhesive resin cement.

-

Citations

Citations to this article as recorded by- Bonding effectiveness of 10-MDP containing resin composite cements: a systematic review with meta-analysis

Sofia Bignotto de Carvalho, Lívia Maiumi Uehara, João Marcos Carvalho-Silva, Andréa Cândido dos Reis

International Journal of Adhesion and Adhesives.2026; 146: 104260. CrossRef - Comparative Evaluation of Color Stability in Bioactive and Conventional Resin Cements Under Thermal Stress Conditions

Alaa Turkistani, Hanin E. Yeslam

Biomimetics.2025; 10(7): 432. CrossRef - Influence of temperature and curing modes on polymerization of self-adhesive resin cements

Hae-In Kim, Jin-Woo Kim, Se-Hee Park, Kyung-Mo Cho

Korean Journal of Dental Materials.2025; 52(3): 143. CrossRef - Clinical Performance and Retention of Partial Implant Restorations Cemented with Fuji Plus® and DentoTemp™: A Retrospective Clinical Study with Mechanical Validation

Sergiu-Manuel Antonie, Laura-Cristina Rusu, Ioan-Achim Borsanu, Remus Christian Bratu, Emanuel-Adrian Bratu

Medicina.2025; 61(12): 2183. CrossRef - A thorough assessment of 10-MDP primers in modern dental adhesive systems

Ahmed A Abduljawad, Harraa SM Salih, Omar F Tawfiq

Journal of Baghdad College of Dentistry.2024; 36(3): 79. CrossRef - Material properties and finite element analysis of adhesive cements used for zirconia crowns on dental implants

Megha Satpathy, Hai Pham, Shreya Shah

Computer Methods in Biomechanics and Biomedical Engineering.2024; : 1. CrossRef - Clinical reliability of self-adhesive luting resins compared to other adhesive procedures: A systematic review and meta-analysis

Mohammed Ahmed Alghauli, Ahmed Yaseen Alqutaibi, Sebastian Wille, Matthias Kern

Journal of Dentistry.2023; 129: 104394. CrossRef - Influence of autoclave sterilization on bond strength between zirconia frameworks and Ti-base abutments using different resin cements

Reinhold Lang, Karl-Anton Hiller, Lena Kienböck, Katrin Friedl, Karl-Heinz Friedl

The Journal of Prosthetic Dentistry.2022; 127(4): 617.e1. CrossRef - Varying 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP) level improves polymerisation kinetics and flexural strength in self-adhesive, remineralising composites

António H.S. Delgado, Nazanin Owji, Paul Ashley, Anne M. Young

Dental Materials.2021; 37(9): 1366. CrossRef - Investigating a Commercial Functional Adhesive with 12-MDPB and Reactive Filler to Strengthen the Adhesive Interface in Eroded Dentin

Madalena Belmar da Costa, António HS Delgado, Tomás Amorim Afonso, Luís Proença, Ana Sofia Ramos, Ana Mano Azul

Polymers.2021; 13(20): 3562. CrossRef

- Bonding effectiveness of 10-MDP containing resin composite cements: a systematic review with meta-analysis

- 2,801 View

- 17 Download

- 10 Crossref

- The effect of thermocycling on the degree of conversion and mechanical properties of a microhybrid dental resin composite

- Mehrsima Ghavami-Lahiji, Melika Firouzmanesh, Hossein Bagheri, Tahereh S. Jafarzadeh Kashi, Fateme Razazpour, Marjan Behroozibakhsh

- Restor Dent Endod 2018;43(2):e26. Published online April 26, 2018

- DOI: https://doi.org/10.5395/rde.2018.43.e26

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

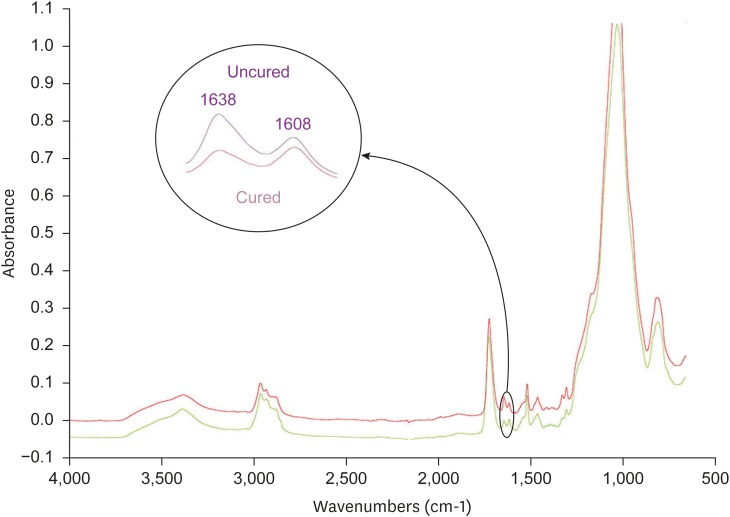

ePub Objective The purpose of this study was to investigate the degree of conversion (DC) and mechanical properties of a microhybrid Filtek Z250 (3M ESPE) resin composite after aging.

Method The specimens were fabricated using circular molds to investigate Vickers microhardness (Vickers hardness number [VHN]) and DC, and were prepared according to ISO 4049 for flexural strength testing. The initial DC (%) of discs was recorded using attenuated total reflectance-Fourier transforming infrared spectroscopy. The initial VHN of the specimens was measured using a microhardness tester under a load of 300 g for 15 seconds and the flexural strength test was carried out with a universal testing machine (crosshead speed, 0.5 mm/min). The specimens were then subjected to thermocycling in 5°C and 55°C water baths. Properties were assessed after 1,000–10,000 cycles of thermocycling. The surfaces were evaluated using scanning electron microscopy (SEM). Data were analyzed using 1-way analysis of variance followed by the Tukey honest significant difference

post hoc test.Results Statistical analysis showed that DC tended to increase up to 4,000 cycles, with no significant changes. VHN and flexural strength values significantly decreased upon thermal cycling when compared to baseline (

p < 0.05). However, there was no significant difference between initial and post-thermocycling VHN results at 1,000 cycles. SEM images after aging showed deteriorative changes in the resin composite surfaces.Conclusions The Z250 microhybrid resin composite showed reduced surface microhardness and flexural strength and increased DC after thermocycling.

-

Citations

Citations to this article as recorded by- Color Stability Under Challenge: Effects of Thermo-Aging and Mouthrinse Exposure on Anterior Teeth and Esthetic Composites

Gökçe Keçeci, Zehra Güner, Süleyman Ziya Şenyurt, Kamile Erciyas

European Journal of Therapeutics.2026; 32(1): 94. CrossRef - Evaluation of surface roughness of PEEK and Laser-Sintered cobalt–chromium subjected to different polishing protocols and thermocycling (an in vitro study)

Marzia Kareem Ahmed, Aras Maruf Rauf

Oxford Open Materials Science.2026;[Epub] CrossRef - Comparative influence of triton and cavity conditioners on the surface characteristics and bond strength of dentin, indicating triton as a cavity conditioner

Lena Bal, Cangül Keskin, Aybüke Karaca Sakallı, Bilge Özcan

Journal of Health Sciences and Medicine.2026; 9(1): 98. CrossRef - The Influence of Thermal and Mechanical Aging on the Flexural Properties of Conventional and 3D-Printed Materials Used in Occlusal Splints Manufacturing

Joanna Smardz, Katarzyna Kresse-Walczak, Heike Meißner, Klaus Böning, Joanna Weżgowiec, Andrzej Małysa, Mieszko Więckiewicz

Materials.2026; 19(2): 421. CrossRef - Failure mechanism analysis and machine learning-based residual strength prediction of CFRP with different ply orientations and loading types under six typical accelerated aging environments

Guofeng Qin, Chenglong Su, Peiwen Mi, Peng Huang, Qiuhan Fan, Ming Li, Wei Tan

Construction and Building Materials.2026; 516: 145630. CrossRef - Discoloration, radiopacity, and push-out bond strength of bismuth-based radiopacifiers in endodontic sealers

Mohammad Ali Saghiri, Mina Shekarian, Amir Abdolmaleki, Michael Conte, Steven M. Morgano

Odontology.2026;[Epub] CrossRef - Clinical Decision‐Making of Repair vs. Replacement of Defective Direct Dental Restorations: A Multinational Cross‐Sectional Study With Meta‐Analysis

Ömer Hatipoğlu, João Filipe Brochado Martins, Mohmed Isaqali Karobari, Nessrin Taha, Thiyezen Abdullah Aldhelai, Daoud M. Ayyad, Ahmed A. Madfa, Benjamin Martin‐Biedma, Rafael Fernández‐Grisales, Bakhyt A. Omarova, Wen Yi Lim, Suha Alfirjani, Kacper Nijak

Journal of Esthetic and Restorative Dentistry.2025; 37(4): 977. CrossRef - An In Vitro Evaluation of Novel Bioactive Liner's Effect on Marginal Adaptation of Class II Composite Restorations: A Scanning Electron Microscope Analysis

Girija S Sajjan, Naveena Ponnada, Praveen Dalavai, Madhu Varma Kanumuri, Venkata Karteek Varma Penmatsa, B V Sindhuja

World Journal of Dentistry.2025; 15(9): 749. CrossRef - Different contemporary resin cements for intracanal luting of glass fiber posts - Bonding and polymerization assessments

Anna Caroliny Detogni, Vitaliano Gomes de Araújo Neto, Caio Felipe de Almeida Nobre, Victor Pinheiro Feitosa, Mário Alexandre Coelho Sinhoreti

International Journal of Adhesion and Adhesives.2025; 138: 103951. CrossRef - Effect of food-simulating liquids and polishing times on the color stability of microhybrid and nanohybrid resin composites

Muhammet Fidan, Nevin Çankaya

Discover Nano.2025;[Epub] CrossRef - Effect of irrigation protocols for post space preparation on the bond of the resin luting agent and post to a hydraulic calcium silicate filled root: An in vitro study

Nuttanun Poeaim, Sirawut Hiran-us, Yanee Tantilertanant

The Journal of Prosthetic Dentistry.2025; 133(4): 1039.e1. CrossRef - Influence of Different Adhesives and Surface Treatments on Shear and Tensile Bond Strength and Microleakage with Micro-CT of Repaired Bulk-Fill Composites

Handan Yıldırım-Işık, Mediha Büyükgöze-Dindar

Polymers.2025; 17(12): 1680. CrossRef - Effect of thermal ageing on physico-mechanical properties and self-healing potential of experimental 3D-printed denture base resin composites

Mariam Raza Syed, Amr Fawzy

Journal of the Mechanical Behavior of Biomedical Materials.2025; 170: 107123. CrossRef - Effects of aging on the physicomechanical, antimicrobial, and cytotoxicity properties of flowable composite resin with strontium-modified phosphate-based glass

Seo-Hyun Kim, Hye-Bin Go, Myung-Jin Lee, Jae-Sung Kwon

Scientific Reports.2025;[Epub] CrossRef - Colour Stability and Optical Properties of Provisional Crowns Fabricated With Milling, 3D Printing, and Direct Technique

Tommaso Rinaldi, Carlos Serrano Granger, Andrea Santamaría Laorden, Jaime Orejas-Perez, Pablo Gómez Cogolludo

International Dental Journal.2025; 75(6): 103932. CrossRef - EVALUATE DEGREE OF CONVERSION OF NEW BIOACTIVE ORTHODONTIC ADHESIVE WITH COLOR CHANGE & FLUORESCENCE PROPERTY

Mohammed Younis, Neam Fakhri Neam Fakhri

BULLETIN OF STOMATOLOGY AND MAXILLOFACIAL SURGERY.2025; : 39. CrossRef - Antibacterial activity and physicochemical properties of light-curable fluoride varnishes containing strontium phosphate-based glass

Na-Yeon Kim, Mi-Sol Ryu, Ji-Min Lee, Soo-Yeon Jeong, Hye-Been Choi, Myung-Jin Lee, Song-Yi Yang

Clinical Oral Investigations.2025;[Epub] CrossRef - Systematic Review of Studies Comparing Microleakage After Restoration With Cention and Conventional Glass Ionomer Cement in Human Extracted Teeth

Rashmi Misra, Mansi Vandekar, Gayatri Pendse, Omkar Bhosale, Pauravi Hegde, Aashaka Vaishnav

Cureus.2025;[Epub] CrossRef - Evaluation of the radiopacity of different universal composite resins aged by thermocycling

Dilber Çölkesen, Alican Kuran, Neslihan Tekçe

Odontology.2025;[Epub] CrossRef - Exploring the sources and routes of micro- and nanoplastics from dental products and materials: their impact on human health - a systematic review

Vidhya Selvaraj, R. Saravanan, N. Raj Vikram, Uma revathi Gopalakrishnan, Ramsamy M

Next Research.2025; 2(4): 100925. CrossRef - Investigation of the mechanical response of MWCNTs infused carbon/glass fiber-based hybrid composites using digital image correlation

Somaiah Chowdary Mallampati, Ujendra Kumar Komal, Paladugu Rakesh, Parthapratim Barman

Construction and Building Materials.2025; 492: 143068. CrossRef - Mechanical, Surface and Physicochemical Properties of Nanozeolite‐Modified 3D Printed Hybrid Ceramics at Varying Concentrations: An In Vitro Study

Ahmed A. Holiel, Yomna M. Ibrahim, Noha Morsy

Journal of Esthetic and Restorative Dentistry.2025;[Epub] CrossRef - Impact of Graphitic Carbon Nitride on Dental Composite’s Mechanical and Antibacterial Properties

Zainab Rafaqat, Saad Liaqat, Ahmed Bari, Warda Khan Yousafzai, Umar Nishan, Sandleen Feroz, Nawshad Muhammad

Journal of Materials Engineering and Performance.2025;[Epub] CrossRef - Exploring the Biological and Chemical Properties of Emerging 3D-Printed Dental Resin Composites Compared to Conventional Light-Cured Materials

Nikola Živković, Stefan Vulović, Miloš Lazarević, Anja Baraba, Aleksandar Jakovljević, Mina Perić, Jelena Mitrić, Aleksandra Milić Lemić

Materials.2025; 18(22): 5170. CrossRef - Awareness of possible complications associated with direct composite restorations: A multinational survey among dentists from 13 countries with meta-analysis

Anna Lehmann, Kacper Nijakowski, Jakub Jankowski, David Donnermeyer, Paulo J. Palma, Milan Drobac, João Filipe Brochado Martins, Fatma Pertek Hatipoğlu, Indira Tulegenova, Muhammad Qasim Javed, Hamad Mohammad Alharkan, Olga Bekjanova, Sylvia Wyzga, Moataz

Journal of Dentistry.2024; 145: 105009. CrossRef - Comparative evaluation of bond strength and color stability of polyetheretherketone and zirconia layered with indirect composite before and after thermocycling: An in vitro study

Pooja Singh, Subhabrata Maiti, Amrutha Shenoy

The Journal of Indian Prosthodontic Society.2024; 24(3): 252. CrossRef - Biaxial flexural strength of hydrothermally aged resin-based materials

Rodrigo Ricci Vivan, Mariana Miranda de Toledo Piza, Bruna de Mello Silva, Thalya Fernanda Horsth Maltarollo, Gustavo Sivieri-Araujo, Murilo Priori Alcalde, Marco Antonio Hungaro Duarte, Estevam Augusto Bonfante, Henrico Badaoui Strazzi-Sahyon

Journal of the Mechanical Behavior of Biomedical Materials.2024; 155: 106568. CrossRef - Comparative Strength Study of Indirect Permanent Restorations: 3D-Printed, Milled, and Conventional Dental Composites

João Paulo Mendes Tribst, Adelheid Veerman, Gabriel Kalil Rocha Pereira, Cornelis Johannes Kleverlaan, Amanda Maria de Oliveira Dal Piva

Clinics and Practice.2024; 14(5): 1940. CrossRef - Influencia del termociclado sobre la estabilidad del color de dos resinas compuestas

//Influence of thermocycling on the color stability of two composite resins

Verónica Lucía Ventrera, María Eugenia Alejandra Barrionuevo

Revista de la Asociación Odontológica Argentina.2024; : 1. CrossRef - Efeito do protocolo de polimento e do armazenamento em meio úmido na variação de cor, massa e rugosidade superficial de resinas compostas

Leonardo Cruz Morais, Mateus Victória Gontijo, Gabriela Rodrigues Pires, Victor de Morais Gomes, Milton Carlos Kuga, Francisco Fernando Massola Filho, Amanda Gonçalves Franco, Alberto Nogueira da Gama Antunes

Cuadernos de Educación y Desarrollo.2024; 16(6): e4556. CrossRef - A comparison of the mechanical properties of 3D-printed, milled, and conventional denture base resin materials

Hyeong-Ju YU, You-Jung KANG, Yeseul PARK, Hoon KIM, Jee-Hwan KIM

Dental Materials Journal.2024; 43(6): 813. CrossRef - Effect of aging and fiber‐reinforcement on color stability, translucency, and microhardness of single‐shade resin composites versus multi‐shade resin composite

Muhammet Fidan, Özhan Yağci

Journal of Esthetic and Restorative Dentistry.2024; 36(4): 632. CrossRef - Impact of Artificial Aging on the Physical and Mechanical Characteristics of Denture Base Materials Fabricated via 3D Printing

Ahmed Altarazi, Julfikar Haider, Abdulaziz Alhotan, Nick Silikas, Hugh Devlin, Weihao Yuan

International Journal of Biomaterials.2024;[Epub] CrossRef - Synthesis, monomer conversion, and mechanical properties of polylysine based dental composites

Saadia Bano Lone, Rabia Zeeshan, Hina Khadim, Muhammad Adnan Khan, Abdul Samad Khan, Anila Asif

Journal of the Mechanical Behavior of Biomedical Materials.2024; 151: 106398. CrossRef - Bond strength and surface roughness assessment of novel antimicrobial polymeric coated dental cement

Ghada Naguib, Hisham Mously, Jumana Mazhar, Ibrahim Alkanfari, Abdulelah Binmahfooz, Mohammed Zahran, Mohamed T. Hamed

Discover Nano.2024;[Epub] CrossRef - Evaluation of microhardness, degree of conversion, and abrasion resistance of nanoglass and multiwalled carbon nanotubes reinforced three‐dimensionally printed denture base resins

Pansai Ashraf Mohamed, Yomna Mohamed Ibrahim, Kenda Ibrahim Hisham Hanno, Mohamed Mahmoud Abdul‐Monem

Journal of Prosthodontics.2024;[Epub] CrossRef - Effect of CAD-CAM block thickness and translucency on the polymerization of luting materials

Bengü Doğu Kaya, Selinsu Öztürk, Ayşe Aslı Şenol, Erkut Kahramanoğlu, Pınar Yılmaz Atalı, Bilge Tarçın

BMC Oral Health.2024;[Epub] CrossRef - Simulation of oral environmental conditions through artificial aging of teeth for the assessment of enamel discoloration in orthodontics

Celal Irgın

BMC Oral Health.2024;[Epub] CrossRef - Do universal adhesive systems affect color coordinates and color change of single-shade resin composites compared with a multi-shade composite?

Muhammet FİDAN, Özhan YAĞCI

Dental Materials Journal.2023; 42(6): 886. CrossRef - Fabrication, Evaluation, and Performance Ranking of Tri-calcium Phosphate and Silica Reinforced Dental Resin Composite Materials

Sonu Saini, Anoj Meena, Ramkumar Yadav, Amar Patnaik

Silicon.2023; 15(18): 8045. CrossRef - Can Modification with Urethane Derivatives or the Addition of an Anti-Hydrolysis Agent Influence the Hydrolytic Stability of Resin Dental Composite?

Agata Szczesio-Wlodarczyk, Izabela M. Barszczewska-Rybarek, Marta W. Chrószcz-Porębska, Karolina Kopacz, Jerzy Sokolowski, Kinga Bociong

International Journal of Molecular Sciences.2023; 24(5): 4336. CrossRef - Effect of veneering material type and thickness ratio on flexural strength of bi-layered PEEK restorations before and after thermal cycling

Ahmed Gouda, Ashraf Sherif, Mennatallah Wahba, Tarek Morsi

Clinical Oral Investigations.2023; 27(6): 2629. CrossRef - 3D printed denture base material: The effect of incorporating TiO2 nanoparticles and artificial ageing on the physical and mechanical properties

Ahmed Altarazi, Julfikar Haider, Abdulaziz Alhotan, Nick Silikas, Hugh Devlin

Dental Materials.2023; 39(12): 1122. CrossRef - Influence of silane coupling agent and aging on the repair bond strength of dental composites

Gustavo Jusué-Esparza, José Alejandro Rivera-Gonzaga, Guillermo Grazioli, Ana Josefina Monjarás-Ávila, J. Eliezer Zamarripa-Calderón, Carlos Enrique Cuevas-Suárez

Journal of Adhesion Science and Technology.2023; 37(5): 913. CrossRef - Degree of conversion of light‐polymerized composite resin in implant prosthesis screw access opening

Se‐Hyun Park, Yoon‐Hyuk Huh, Chan‐Jin Park, Lee‐Ra Cho, Kyung‐Ho Ko

Journal of Prosthodontics.2023; 32(9): 829. CrossRef - Investigation of the effect of matrix-interface formed with silane-based coupling agents on physico-chemical behavior and flow distance of dental composites

Zerin Yeşil Acar, Merve Tunç Koçyiğit, Meltem Asiltürk

Journal of Molecular Liquids.2023; 378: 121600. CrossRef - Evaluation of Water Sorption and Solubility of 3D-Printed, CAD/CAM Milled, and PMMA Denture Base Materials Subjected to Artificial Aging

Mariya Dimitrova, Angelina Vlahova, Ilian Hristov, Rada Kazakova, Bozhana Chuchulska, Stoyan Kazakov, Marta Forte, Vanja Granberg, Giuseppe Barile, Saverio Capodiferro, Massimo Corsalini

Journal of Composites Science.2023; 7(8): 339. CrossRef - Effect of thermocycling on internal microhardness of high and low viscosity bulk fill composite resins in class I cavities

Sâmara Luciana de Andrade LIMA, Lais Lemos CABRAL, Natália Russo CARLOS, Saulo André de Andrade LIMA, Kamila Rosamilia KANTOVITZ, Flávia Lucisano Botelho do AMARAL

RGO - Revista Gaúcha de Odontologia.2023;[Epub] CrossRef - Effects of an Acidic Environment on the Strength and Chemical Changes of Resin-based Composites

S Kang, B-H Cho

Operative Dentistry.2023; 48(4): E81. CrossRef - Influence of compressive forces and aging through thermocycling on the strength of mono incremental dental composite resins

Cristian Roberto Sigcho Romero, Henry Fabricio Mejía Mosquera, Sandra Marcela Quisiguiña Guevara, Yudy Jacqueline Alvarado Aguayo

Bionatura.2023; 8(4): 1. CrossRef - Push-out Bond Strength of Two Fiber Posts in Composite Resin Using Different Types of Silanization

RM Novis, BLT Leon, FMG França, CP Turssi, RT Basting, FLB Amaral

Operative Dentistry.2022; 47(2): 173. CrossRef - Penetration and Adaptation of the Highly Viscous Zinc-Reinforced Glass Ionomer Cement on Contaminated Fissures: An In Vitro Study with SEM Analysis

Galiah AlJefri, Sunil Kotha, Muhannad Murad, Reham Aljudaibi, Fatmah Almotawah, Sreekanth Mallineni

International Journal of Environmental Research and Public Health.2022; 19(10): 6291. CrossRef - Surface Characteristics and Color Stability of Dental PEEK Related to Water Saturation and Thermal Cycling

Liliana Porojan, Flavia Roxana Toma, Mihaela Ionela Bîrdeanu, Roxana Diana Vasiliu, Ion-Dragoș Uțu, Anamaria Matichescu

Polymers.2022; 14(11): 2144. CrossRef - Effects of aging and light-curing unit type on the volume and internal porosity of bulk-fill resin composite restoration

Afnan O. Al-Zain, Elaf A. Alboloshi, Walaa A. Amir, Maryam A. Alghilan, Eliseu A. Münchow

The Saudi Dental Journal.2022; 34(3): 243. CrossRef - An Evaluation of the Hydrolytic Stability of Selected Experimental Dental Matrices and Composites

Agata Szczesio-Wlodarczyk, Karolina Kopacz, Malgorzata Iwona Szynkowska-Jozwik, Jerzy Sokolowski, Kinga Bociong

Materials.2022; 15(14): 5055. CrossRef - Comparison of the Mechanical Properties and Push-out Bond Strength of Self-adhesive and Conventional Resin Cements on Fiber Post Cementation

MR Santi, RBE Lins, BO Sahadi, JR Soto-Montero, LRM Martins

Operative Dentistry.2022; 47(3): 346. CrossRef - Effect of Different Polymerization Times on Color Change, Translucency Parameter, and Surface Hardness of Bulk-Fill Resin Composites

HY Gonder, M Fidan

Nigerian Journal of Clinical Practice.2022; 25(10): 1751. CrossRef - Surface degradation and biofilm formation on hybrid and nanohybrid composites after immersion in different liquids

Gabriela Escamilla-Gómez, Octavio Sánchez-Vargas, Diana M. Escobar-García, Amaury Pozos-Guillén, Norma V. Zavala-Alonso, Mariana Gutiérrez-Sánchez, José E. Pérez-López, Gregorio Sánchez-Balderas, Gabriel F. Romo-Ramírez, Marine Ortiz-Magdaleno

Journal of Oral Science.2022; 64(4): 263. CrossRef - Effects of Different Adhesive Systems and Orthodontic Bracket Material on Enamel Surface Discoloration: An In Vitro Study

Ali Alqerban, Doaa R. M. Ahmed, Ali S. Aljhani, Dalal Almadhi, Amjad AlShahrani, Hussah AlAdwene, Abdulaziz Samran

Applied Sciences.2022; 12(24): 12885. CrossRef - Effects of Immediate Coating on Unset Composite with Different Bonding Agents to Surface Hardness

Nantawan Krajangta, Supissara Ninbanjong, Sunisa Khosook, Kanjana Chaitontuak, Awiruth Klaisiri

European Journal of Dentistry.2022; 16(04): 828. CrossRef - Rational durability of optical properties of chameleon effect of Omnichroma and Essentia composite thermocycled in black dark drinks (in vitro study)

Bassma Abdelhamed, Asmaa Abdel-Hakeem Metwally, Heba A. Shalaby

Bulletin of the National Research Centre.2022;[Epub] CrossRef - Comparative Evaluation of Shear Bond Strength of Nanohybrid Composite Restoration After the Placement of Flowable Compomer and Composite Using the Snowplow Technique

Meghna Dugar, Anuja Ikhar, Pradnya Nikhade, Manoj Chandak, Nidhi Motwani

Cureus.2022;[Epub] CrossRef - The First Step in Standardizing an Artificial Aging Protocol for Dental Composites—Evaluation of Basic Protocols

Agata Szczesio-Wlodarczyk, Magdalena Fronczek, Katarzyna Ranoszek-Soliwoda, Jarosław Grobelny, Jerzy Sokolowski, Kinga Bociong

Molecules.2022; 27(11): 3511. CrossRef - Effect of Different Surface Treatments on the Long‐Term Repair Bond Strength of Aged Methacrylate‐Based Resin Composite Restorations: A Systematic Review and Network Meta‐analysis

Mahdi Hadilou, Amirmohammad Dolatabadi, Morteza Ghojazadeh, Hossein Hosseinifard, Parnian Alizadeh Oskuee, Fatemeh Pournaghi Azar, Victor Feitosa

BioMed Research International.2022;[Epub] CrossRef - Edge chipping resistance of veneering composite resins

Parissa Nassary Zadeh, Bogna Stawarczyk, Rüdiger Hampe, Anja Liebermann, Felicitas Mayinger

Journal of the Mechanical Behavior of Biomedical Materials.2021; 116: 104349. CrossRef - The effect of radiation exposure and storage time on the degree of conversion and flexural strength of different resin composites

Ragia M. Taher, Lamiaa M. Moharam, Amin E. Amin, Mohamed H. Zaazou, Farid S. El-Askary, Mokhtar N. Ibrahim

Bulletin of the National Research Centre.2021;[Epub] CrossRef - Fracture Load of CAD/CAM Fabricated Cantilever Implant-Supported Zirconia Framework: An In Vitro Study

Ibraheem F. Alshiddi, Syed Rashid Habib, Muhammad Sohail Zafar, Salwa Bajunaid, Nawaf Labban, Mohammed Alsarhan

Molecules.2021; 26(8): 2259. CrossRef - A numerical, theoretical and experimental study of the effect of thermocycling on the matrix-filler interface of dental restorative materials

Yoan Boussès, Nathalie Brulat-Bouchard, Pierre-Olivier Bouchard, Yannick Tillier

Dental Materials.2021; 37(5): 772. CrossRef - Impact of polymerization and storage on the degree of conversion and mechanical properties of veneering resin composites

Felicitas MAYINGER, Marcel REYMUS, Anja LIEBERMANN, Marc RICHTER, Patrick KUBRYK, Henning GROẞEKAPPENBERG, Bogna STAWARCZYK

Dental Materials Journal.2021; 40(2): 487. CrossRef - Intrapulpal Concentration of Hydrogen Peroxide of Teeth Restored With Bulk Fill and Conventional Bioactive Composites

DP Silva, BA Resende, M Kury, CB André, CPM Tabchoury, M Giannini, V Cavalli

Operative Dentistry.2021; 46(3): E158. CrossRef - Silane content influences physicochemical properties in nanostructured model composites

Larissa Maria Cavalcante, Lucielle Guimarães Ferraz, Karinne Bueno Antunes, Isadora Martini Garcia, Luis Felipe Jochims Schneider, Fabrício Mezzomo Collares

Dental Materials.2021; 37(2): e85. CrossRef - AĞIZ GARGARALARI VE ANTİSEPTİKLERİNİN FARKLI KOMPOZİT REZİNLERİN RENK STABİLİTESİNE ETKİSİ

Turan Emre KUZU, Özcan KARATAŞ

Atatürk Üniversitesi Diş Hekimliği Fakültesi Dergisi.2021; : 1. CrossRef - Evaluation of Immediate and Delayed Microleakage of Class V Cavities Restored with Chitosan-incorporated Composite Resins: An In Vitro Study

Roopa R Nadig, Veena Pai, Arpita Deb

International Journal of Clinical Pediatric Dentistry.2021; 14(5): 621. CrossRef - Influence of Diode Laser for the Treatment of Dentin Hypersensitivity on Microleakage of Cervical Restorations

Doaa R. M. Ahmed, Diana G. Shaath, Jomana B. Alakeel, Abdulaziz A. Samran, Mona Abbassy

BioMed Research International.2021;[Epub] CrossRef - Ageing of Dental Composites Based on Methacrylate Resins—A Critical Review of the Causes and Method of Assessment

Agata Szczesio-Wlodarczyk, Jerzy Sokolowski, Joanna Kleczewska, Kinga Bociong

Polymers.2020; 12(4): 882. CrossRef - Flexural strength and surface microhardness of materials used for temporary dental disocclusion submitted to thermal cycling: An in vitro study

Tamires Borges de Lima, José Guilherme Neves, Ana Paula Terossi de Godoi, Ana Rosa Costa, Viviane Veroni Degan, Américo Bortolazzo Correr, Heloisa Cristina Valdrighi

International Orthodontics.2020; 18(3): 519. CrossRef - Evaluation of the repair capacities and color stabilities of a resin nanoceramic and hybrid CAD/CAM blocks

Hasibe Sevilay Bahadır, Yusuf Bayraktar

The Journal of Advanced Prosthodontics.2020; 12(3): 140. CrossRef - Effect of Different Surface Treatments of Resin Relined Fiber Posts Cemented With Self-adhesive Resin Cement on Push-out and Microtensile Bond Strength Tests

RV Machry, PE Fontana, TC Bohrer, LF Valandro, OB Kaizer

Operative Dentistry.2020; 45(4): E185. CrossRef - Influences of Successive Exposure to Bleaching and Fluoride Preparations on the Surface Hardness and Roughness of the Aged Resin Composite Restoratives

Khalid M. Abdelaziz, Shugufta Mir, Shafait Ullah Khateeb, Suheel M. Baba, Saud S. Alshahrani, Eman A. Alshahrani, Zahra A. Alsafi

Medicina.2020; 56(9): 476. CrossRef - Fracture Resistance of Lithıum Disilicate, Indirect Resin Composite and Zirconıa by Using Dual Cure Resin Cements

Mohammed BADWAN, Erkut KAHRAMANOĞLU

Clinical and Experimental Health Sciences.2020; 10(4): 435. CrossRef - Effect of Stress-decreasing Resin Thickness as an Intermediate Layer on Fracture Resistance of Class II Composite Restoration: An In Vitro Study

Dennis Dennis, Arwin Leonardy, Trimurni Abidin

World Journal of Dentistry.2020; 11(2): 91. CrossRef - Effect of Thermocycling on Biaxial Flexural Strength of CAD/CAM, Bulk Fill, and Conventional Resin Composite Materials

EB Benalcázar Jalkh, CM Machado, M Gianinni, I Beltramini, MMT Piza, PG Coelho, R Hirata, EA Bonfante

Operative Dentistry.2019; 44(5): E254. CrossRef - Mechanical properties of hybrid computer-aided design/computer-aided manufacturing (CAD/CAM) materials after aging treatments

Hae-Yong Jeong, Hae-Hyoung Lee, Yu-Sung Choi

Ceramics International.2018; 44(16): 19217. CrossRef

- Color Stability Under Challenge: Effects of Thermo-Aging and Mouthrinse Exposure on Anterior Teeth and Esthetic Composites

- 6,897 View

- 59 Download

- 83 Crossref

- Effect of water storage on flexural strength of silorane and methacrylate-based composite resins

- Narges Panahandeh, Hassan Torabzadeh, Hani Naderi, Seyedeh Mahsa Sheikh-Al-Eslamian

- Restor Dent Endod 2017;42(4):309-315. Published online November 6, 2017

- DOI: https://doi.org/10.5395/rde.2017.42.4.309

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives This study assessed the effect of water storage on the flexural strength (FS) of low shrinkage composites.

Materials and Methods A total of 165 bar-shaped specimens (2 × 2 × 25 mm) were fabricated of 2 low shrinkage composites (Filtek P90 [3M ESPE], GC Kalore [GC International]) and a conventional methacrylate-based composite (Filtek Z250 [3M ESPE]). The specimens were subjected to 3-point bending test at 6 time intervals, namely: immediately after curing, at 24 hours, 1 week, 1 month, 6 months, and 1 year following storage in wet and dry conditions. The FS of the specimens were measured by applying compressive load at a crosshead speed of 1.0 mm/min. Data was analyzed using 3-way analysis of variance (ANOVA) and Tukey's test.

Results Three-way ANOVA revealed significant interactions between time, type of composite, and storage condition (

p = 0.001). Tukey's multiple comparison test revealed significant reductions in FS of all composites after 6 months and 1 year of storage in distilled water compared to dry condition.Conclusions Filtek P90 showed the highest and GC Kalore showed the lowest FS after 1 year storage in distilled water. The immediate high strength of Filtek Z250 significantly decreased at 1 year and its final value was lower than that of Filtek P90.

-

Citations

Citations to this article as recorded by- Graphene–Catechol Dental Sealant: Antibacterial and Mechanical Evaluation

Renata Pereira, Flávio H. B. Aguiar, Rodrigo B. E. Lins, Maria C. A. J. Mainairdi, Bruna G. Silva, Marcela A. Ferretti, Klaus Rischka

Advanced Engineering Materials.2025;[Epub] CrossRef - Effects of Bio-Aging on Mechanical Properties and Microbial Behavior of Different Resin Composites

Yuke Shou, Lanzhi Deng, Xiaoyu Huang, Xinyu Peng, Xinxuan Zhou, Zheng Wang, Yannan Huang, Bina Yang, Haohao Wang, Min Zhang, Lei Cheng

Biomolecules.2023; 13(7): 1125. CrossRef - Changes in color and contrast ratio of resin composites after curing and storage in water

Marlus da Silva Pedrosa, Fernando Neves Nogueira, Vitor de Oliveira Baldo, Igor Studart Medeiros

The Saudi Dental Journal.2021; 33(8): 1160. CrossRef - Ageing of Dental Composites Based on Methacrylate Resins—A Critical Review of the Causes and Method of Assessment

Agata Szczesio-Wlodarczyk, Jerzy Sokolowski, Joanna Kleczewska, Kinga Bociong

Polymers.2020; 12(4): 882. CrossRef - Color stability of nanohybrid composite resins in drinks

Juliana Jendiroba Faraoni, Isabela Barbosa Quero, Lívia Semedo Schiavuzzo, Regina Guenka Palma-Dibb

Brazilian Journal of Oral Sciences.2019; 18: e191601. CrossRef - Mechanical Degradation of Different Classes of Composite Resins Aged in Water, Air, and Oil

Weber Adad Ricci, Priscila Alfano, Saulo Pamato, Carlos Alberto dos Santos Cruz, Jefferson Ricardo Pereira

BioMed Research International.2019; 2019: 1. CrossRef - Effects of water and microbial-based aging on the performance of three dental restorative materials

Xinxuan Zhou, Suping Wang, Xian Peng, Yao Hu, Biao Ren, Mingyun Li, Liying Hao, Mingye Feng, Lei Cheng, Xuedong Zhou

Journal of the Mechanical Behavior of Biomedical Materials.2018; 80: 42. CrossRef

- Graphene–Catechol Dental Sealant: Antibacterial and Mechanical Evaluation

- 1,651 View

- 6 Download

- 7 Crossref

- Flexural strength and microstructure of two lithium disilicate glass ceramics for CAD/CAM restoration in the dental clinic

- Suk-Ho Kang, Juhea Chang, Ho-Hyun Son

- Restor Dent Endod 2013;38(3):134-140. Published online August 23, 2013

- DOI: https://doi.org/10.5395/rde.2013.38.3.134

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives There has been a growing interest in glass ceramic systems with good esthetics, high fracture resistance and bonding durability, and simplified fabrication techniques using CAD/CAM. The aim of this study is to compare flexural strength before and after heat treatment of two lithium disilicate CAD/CAM blocks, IPS e.max CAD (Ivoclar Vivadent) and Rosetta SM (Hass), and to observe their crystalline structures.

Materials and Methods Biaxial flexural strength was tested according to ISO 6872 with 20 disc form specimens sliced from each block before and after heat treatment. Also, the crystalline structures were observed using field-emission scanning microscopy (FE-SEM, Hitachi) and x-ray diffraction (XRD, Rigaku) analysis. The mean values of the biaxial flexural strength were analyzed by the Mann-Whitney U test at a significance level of

p = 0.05.Results There were no statistically significant differences in flexural strength between IPS e.max CAD and Rosetta SM either before heat treatment or after heat treatment. For both ceramics, the initial flexural strength greatly increased after heat treatment, with significant differences (

p < 0.05). The FE-SEM images presented similar patterns of crystalline structure in the two ceramics. In the XRD analysis, they also had similar patterns, presenting high peak positions corresponding to the standard lithium metasilicate and lithium disilicate at each stage of heat treatment.Conclusions IPS e.max CAD and Rosetta SM showed no significant differences in flexural strength. They had a similar crystalline pattern and molecular composition.

-

Citations

Citations to this article as recorded by- Lithium silicate glass‐ceramics for dental restoration: From fundamental properties to machine‐learning design

Shanshan Liu, Yan Yan, Pijun Gong, Feng He

International Journal of Applied Ceramic Technology.2026;[Epub] CrossRef - Evaluating Translucency and Color Changes in Lithium Disilicate Ceramics After Sintering Modification and Artificial Aging

Mai Soliman, Raghad Alotaibi, Abrar Almutairi, Asma Alzahrani, Reem Abunyan, Aseel Rozi, Dalia Alamri, Shahad Almakenzi, Elzahraa Eldwakhly, Alhanoof Aldegheishem

Inorganics.2026; 14(2): 56. CrossRef - Minimally Invasive Rehabilitation of a Missing Maxillary Lateral Incisor Using a Lithium Disilicate Cantilever Resin-Bonded Prosthesis: A Clinical Case Report

Mohanned M. Toras, Ossama Raffa, Hanaa Ashkar, Faris Alsufi, Loai Alsofi

Prosthesis.2026; 8(2): 17. CrossRef - A novel simplified method for assessing crystal length and crystalline content in dental ceramics

Danilo Cassiano Ferraz, Lucas Nascimento Tavares, Isadora Aparecida Ribeiro Reis, William W. Brackett, Rafael Rocha Pacheco, Luís Henrique Araújo Raposo

Microscopy Research and Technique.2025; 88(1): 224. CrossRef - The Effect of Chewing Simulation on Flexural Strength of Different Lithium Disilicate Ceramics

Osamah Alsulimani, Salah Yousief, Raghad Al-Dabbagh, Esraa Attar, Dalea Bukhary, Hamad Algamaiah, Khadija Musawa, Awatif Subahi, Samar Abuzinadah, Abdulrahman Alhaddad, Waleed Alqahtani, Abdel Naser Emam, Mohammad Alqhtani, Ahmed Elmarakby

Clinical, Cosmetic and Investigational Dentistry.2025; Volume 17: 67. CrossRef - The influence of thermal tempering on the fracture resistance, surface microstructure, elemental surface composition, and phase analysis of four heat-pressed lithia-based glass ceramic crowns

Khaled Nasser, Amr EL-Etreby, Soha Osama Nabih

BMC Oral Health.2025;[Epub] CrossRef - Comparative evaluation of color stability in polished and glazed CAD/CAM ceramics subjected to coffee thermal cycling: an in vitro study

Reza Nahidi, Azita Mazaheri, Shaghayegh Golalipour, Negin Youshaei, Sotude Khorshidi

BMC Oral Health.2025;[Epub] CrossRef - Comparing the Effect of Precrystallization or Postcrystallization Adjustments on Fatigue Behavior of Lithium Disilicate‐Based Ceramics

Abdel Rahim Mohamad Abdel Salam Suleiman, Luiza Freitas Brum Souza, Vinícius Felipe Wandscher, Gabriel Kalil Rocha Pereira, Jovito Adiel Skupien

Journal of Biomedical Materials Research Part B: Applied Biomaterials.2025;[Epub] CrossRef - Biaxial Flexural Strength of Lithium‐Based CAD/CAM Dental Glass‐Ceramics

Saleh Alhindi, Dayane Oliveira, Patricia Pereira, Ali A. Elkaffas, Mateus Rocha

Journal of Esthetic and Restorative Dentistry.2025;[Epub] CrossRef - Impact of Zirconia Coping Overlapped by Lithium Disilicate on Esthetic Outcome: A Systematic Review

Mousa Alrashidy, Raghdah Abdullah Al Thubaiti, Najla Haif Alqahtani, Abdulrahman Kamal Habash, Ruba Abdullah Alkhalil

Cureus.2025;[Epub] CrossRef - Microstructure and mechanical properties of an experimental lithium disilicate dental glass-ceramic

Bruna de F. Vallerini, Laís D. Silva, Mariana de O.C. Villas-Bôas, Oscar Peitl, Edgar D. Zanotto, Lígia A.P. Pinelli

Ceramics International.2024; 50(1): 188. CrossRef - Effect of computer-aided design/computer-aided manufacturing bleach shade ceramic thickness on its light transmittance and microhardness of light-cured resin cement

Pardis Sheibani, Ghazaleh Ahmadizenous, Behnaz Esmaeili, Ali Bijani

Dental Research Journal.2024;[Epub] CrossRef - Effect of “fast”-crystallization and simultaneous glazing on physicochemical properties of lithium-disilicate CAD/CAM ceramic

Fabián Murillo-Gómez, Federico Murillo-Alvarado, Fabián Vásquez-Sancho, Esteban Avendaño, Roberto Urcuyo

Journal of Dentistry.2024; 148: 105257. CrossRef - Quantitative examination of factors influencing the colour reproduction ability of lithium disilicate glass-ceramics

József Saláta, Ferenc Szabó, Péter Csuti, Melinda Antal, Péter Márton, Péter Hermann, Judit Borbély, Emese Ábrám

BMC Oral Health.2024;[Epub] CrossRef - Flexural Strength of Modern CAD/CAM Restoratives After Artificial Aging

Thomas Melc, Thomas Attin, Tan Fırat Eyüboğlu, Mutlu Özcan

Materials.2024; 17(21): 5178. CrossRef - Microstructural and flexural strength of various CAD‐CAM lithium disilicate ceramics

Joissi Ferrari Zaniboni, Amanda Soares Silva, Aryvelto Miranda Silva, João Felipe Besegato, Oscar Fernando Muñoz‐Chávez, Edson Alves de Campos

Journal of Prosthodontics.2024;[Epub] CrossRef - Surface Roughness Evaluation of Pre- Versus Post-Crystallization Polish of Two High-Strength Silicate Ceramics for Chairside CAD/CAM Technology

Felipe Tarosso Rea, Andre Valcanaia, Pilar Herrera-Fierro, Manish Verma, Gisele de Faria Neiva

Applied Sciences.2024; 14(7): 2768. CrossRef - Influence of Finishing and Polishing Procedures on the Surface Characteristics and Flexural Strength of Monolithic Zirconia: An In Vitro Study

Lakshmi Shivasubramanian, Annapoorni Hariharan, Vyshnavi Devi Janagaraj, Vigneswaran Sekar

World Journal of Dentistry.2024; 15(1): 19. CrossRef - Effect of hydrofluoric acid concentration and aging on the bond strength ceramics to a resin cement

Bruno Delgado Clerot, Lourenço Correr-Sobrinho, Milena Bandini, Evaldo Pinheiro Beserra-Neto, Fernanda Midori Tsuzuki, Rafael Rocha Pacheco, Ana Rosa Costa

Brazilian Dental Journal.2024;[Epub] CrossRef - Biaxial flexural strength and Weibull characteristics of a resin ceramic material after thermal‐cycling

Elaheh Beyabanaki, Reza Eftekhar Ashtiani, Mehrnoosh Moradi, Mahshid Namdari, Delaram Mostafavi, Amirali Zandinejad

Journal of Prosthodontics.2023; 32(8): 721. CrossRef - Fit and fatigue behavior of CAD-CAM lithium disilicate crowns

William Garcia Alves, Luiza Freitas Brum Souza, Gabriel Kalil Rocha Pereira, Luiz Felipe Valandro, Myriam Pereira Kapczinski, Cristiane Machado Mengatto, Sara Fraga

The Journal of Prosthetic Dentistry.2023; 130(2): 241.e1. CrossRef - Mechanical Properties of Five Esthetic Ceramic Materials Used for Monolithic Restorations: A Comparative In Vitro Study

Saleh N. Almohammed, Belal Alshorman, Layla A. Abu-Naba’a

Ceramics.2023; 6(2): 1031. CrossRef - The Light Reflection Changes of Monolithic Zirconia and Lithium Disilicate after Using Two External Staining Kits following by Thermocycling

Eran Dolve, Gil Ben-Izhack, Avi Meirowitz, Hadar Erel, Ofir Rosner, Ameer Biadsee, Diva Lugassy, Asaf Shely

Materials.2023; 16(5): 2057. CrossRef - Flexural Strength of CAD/CAM Lithium-Based Silicate Glass–Ceramics: A Narrative Review

Alvaro Munoz, Zejiao Zhao, Gaetano Paolone, Chris Louca, Alessandro Vichi

Materials.2023; 16(12): 4398. CrossRef - Effect of thickness of CAD/CAM materials on light transmission and resin cement polymerization using a blue light‐emitting diode light‐curing unit

Eduardo Fernandes de Castro, Bruna Marin Fronza, Jorge Soto‐Montero, Marcelo Giannini, Carlos Tadeu dos‐Santos‐Dias, Richard Bengt Price

Journal of Esthetic and Restorative Dentistry.2023; 35(2): 368. CrossRef - Fragile Effects of Mobile Phone Emitted Radiations on Agricultural Growth and Ecological Systems

Aqarab Husnain Gondal, Franklin Ore Areche, María Soledad Porras-Roque, Abel Alberto Muñiz Paucarmayta, Marco Herber Muñiz Paucarmayta, Guillermo Gomer Cotrina Cabello, Jorge Washington Rodriguez-Deza

Reviews in Agricultural Science.2023; 11: 137. CrossRef - Ceramics overview

Russell Giordano II

British Dental Journal.2022; 232(9): 658. CrossRef - Digital image analysis of fluorescence of ceramic veneers with different ceramic materials and resin cements

Jiao ZHANG, Qing YU

Dental Materials Journal.2022; 41(6): 868. CrossRef - Microstructural considerations for novel lithium disilicate glass ceramics: A review

Jin‐Ho Phark, Sillas Duarte

Journal of Esthetic and Restorative Dentistry.2022; 34(1): 92. CrossRef - Biaxial flexure strength and physicochemical characterization of a CAD/CAM lithium disilicate ceramic: effect of etching time, silane, and adhesive applications

Sarah Emille Gomes da Silva, Gabriela Monteiro de Araújo, Karina Barbosa Souza, Dayanne Monielle Duarte Moura, Iana Lamadrid Aurélio, Liliana Gressler May, Taciana Emília Leite Vila-Nova, Yu Zhang, Rodrigo Othávio de Assunção e Souza

Clinical Oral Investigations.2022; 26(11): 6753. CrossRef - Mechanical stability of dental CAD-CAM restoration materials made of monolithic zirconia, lithium disilicate, and lithium disilicate–strengthened aluminosilicate glass-ceramic with and without fatigue conditions

Nadin Al-Haj Husain, Tobias Dürr, Mutlu Özcan, Urs Brägger, Tim Joda

The Journal of Prosthetic Dentistry.2022; 128(1): 73. CrossRef - In Vivo Evaluation of the Effects of Sintering Temperature on the Optical Properties of Dental Glass-Ceramics

Kuo-Cheng Fan, Yu-Ling Lin, Hao-Wei Tsao, Hsuan Chen, Sheng-Yang Lee, Yu-Chen Cheng, Hsiao-Ping Huang, Wei-Chun Lin

Nanomaterials.2022; 12(13): 2187. CrossRef - Fracture resistance of pressed ZLS crowns versus pressed LD crowns under thermo-mechanical cycling

Basma Osama Salem, Dina Magdy Elshehawi, Gihan Abdelhady Elnaggar

Brazilian Dental Journal.2022; 33(6): 103. CrossRef - Improving early running-in wear characteristics for dental lithium disilicate glass-ceramics by ion-exchange

T.J. Men, Z.G. Chai, X.C. Li, D. Li, F. Wang, L. He, S.F. Zhang, M. Meng

Journal of the Mechanical Behavior of Biomedical Materials.2022; 126: 105037. CrossRef - Effect of different surface treatments on the biaxial flexure strength, Weibull characteristics, roughness, and surface topography of bonded CAD/CAM silica-based ceramics

Camila Moreira Lima, Nathalia Ramos da Silva, Jordana Dias Martins, Jean Soares Miranda, Ricardo Tanaka, Rodrigo Othávio de Assunção e Souza, Fabíola Pessôa Pereira Leite

Dental Materials.2021; 37(3): e151. CrossRef - Effects of multiple firing processes on the mechanical properties of lithium disilicate glass-ceramics produced by two different production techniques

Alper Ozdogan, Hatice Ozdemir

The Journal of Prosthetic Dentistry.2021; 125(3): 527.e1. CrossRef - The Influence of Surface Roughening and Polishing on Microbial Biofilm Development on Different Ceramic Materials

Mohamed Mahmoud Abdalla, Islam A.A. Ali, Khadija Khan, Nikos Mattheos, Sukhdeep Murbay, Jukka Pekka Matinlinna, Prasanna Neelakantan

Journal of Prosthodontics.2021; 30(5): 447. CrossRef - Comparison of Fracture Load of the Four Translucent Zirconia Crowns

Suchada Kongkiatkamon, Kittipong Booranasophone, Apichat Tongtaksin, Valailuck Kiatthanakorn, Dinesh Rokaya

Molecules.2021; 26(17): 5308. CrossRef - The roles of microstructure and surface energy on subcritical crack growth in glass-ceramics

Pamela Ricco, Nathália de Carvalho Ramos, Tiago Moreira Bastos Campos, Viviane Oliveira Soares, Mariana de Oliveira Carlos Villas Boas, Renata Marques de Melo

Ceramics International.2021; 47(5): 6827. CrossRef - Comparative in-vitro study of marginal gap of four cad/cam all ceramic systems with thermal aging

Fatma A. Hasaneen, Marwa M. Mogahed

Tanta Dental Journal.2021; 18(1): 12. CrossRef - Stress Distribution in Modified Veneer Crowns: 3D Finite Element Analysis

Camila Ferreira Leite Madruga, Gabriela Freitas Ramos, Alexandre Luiz Souto Borges, Guilherme de Siqueira Ferreira Anzaloni Saavedra, Rodrigo Othávio Souza, Renata Marques de Melo Marinho, Marcela Moreira Penteado

Oral.2021; 1(3): 272. CrossRef - Surface Characterization and Conductivity of Two Types of Lithium-Based Glass Ceramics after Accelerating Ageing

Marko Jakovac, Teodoro Klaser, Borna Radatović, Željko Skoko, Luka Pavić, Mark Žic

Materials.2020; 13(24): 5632. CrossRef - Biaxial flexural strength and translucent characteristics of dental lithium disilicate glass ceramics with different translucencies

Fu Wang, Tao Yu, Jihua Chen

Journal of Prosthodontic Research.2020; 64(1): 71. CrossRef - Femtosecond laser micro-milling dental glass ceramics: An experimental analysis and COMSOL finite element simulation

Peixin Hu, Lu Yao, Mingji Zhang, Zilin Nie, Encai Ji, QiTao Lue, Zhengdi He

Ceramics International.2020; 46(14): 22146. CrossRef - Glass–Ceramics in Dentistry: A Review

Le Fu, Håkan Engqvist, Wei Xia

Materials.2020; 13(5): 1049. CrossRef - Effect of staining and repeated firing on the surface and optical properties of lithium disilicate

Jean S. Miranda, Aline S. P. Barcellos, Carolina M. MartinelliLobo, Taciana M. F. Caneppele, Marina Amaral, Estevão T. Kimpara

Journal of Esthetic and Restorative Dentistry.2020; 32(1): 113. CrossRef - Effects of glazing methods on the optical and surface properties of silicate ceramics

Meral Kurt, Merve Bankoğlu Güngör, Seçil Karakoca Nemli, Bilge Turhan Bal

Journal of Prosthodontic Research.2020; 64(2): 202. CrossRef - Microstructural and mechanical analysis of two CAD-CAM lithium disilicate glass-reinforced ceramics

Lucas do Nascimento TAVARES, Karla ZANCOPÉ, Anielle Christine Almeida SILVA, Luís Henrique Araújo RAPOSO, Carlos José SOARES, Flávio Domingues das NEVES

Brazilian Oral Research.2020;[Epub] CrossRef - Fracture Resistance of New Metal-Free Materials Used for CAD-CAM Fabrication of Partial Posterior Restorations

Georgina García-Engra, Lucia Fernandez-Estevan, Javier Casas-Terrón, Antonio Fons-Font, Pablo Castelo-Baz, Rubén Agustín-Panadero, Juan Luis Román-Rodriguez

Medicina.2020; 56(3): 132. CrossRef - Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging

Liliana Porojan, Roxana-Diana Vasiliu, Mihaela-Ionela Bîrdeanu, Sorin-Daniel Porojan

Molecules.2020; 25(15): 3407. CrossRef - Influence of Occlusal Thickness and Radicular Extension on the Fracture Resistance of Premolar Endocrowns from Different All-Ceramic Materials

Satheesh B. Haralur, Alaa Ali Alamri, Shatha Abdulrahman Alshehri, Danyah Saeed Alzahrani, Mohammed Alfarsi

Applied Sciences.2020; 10(8): 2696. CrossRef - Effect of different surface treatments and multimode adhesive application on the Weibull characteristics, wettability, surface topography and adhesion to CAD/CAM lithium disilicate ceramic

Karina Barbosa Souza, Dayanne Monielle Duarte Moura, Sarah Emille Gomes da Silva, Gabriela Monteiro de Araújo, Rafael de Almeida Spinelli Pinto, Fabíola Pessôa Pereira Leite, Mutlu Özcan, Rodrigo Othávio de Assunção e Souza

Journal of Applied Oral Science.2020;[Epub] CrossRef - Splinting of the Anterior Maxillary Teeth Using Glass-Ceramic Materials: A Case Report

Vasilliki Roussou, Aspasia Pachiou, Stefanos Kourtis

The Open Dentistry Journal.2020; 14(1): 711. CrossRef - Influence of Computer-aided Design/Computer-aided Manufacturing Diamond Bur Wear on Marginal Misfit of Two Lithium Disilicate Ceramic Systems

LH Raposo, PS Borella, DC Ferraz, LM Pereira, MS Prudente, PC Santos-Filho

Operative Dentistry.2020; 45(4): 416. CrossRef - Effect of thermal and mechanical cycles on shear bond strength of zirconia core to porcelain veneer under different surface treatments

Tahereh Ghaffari, Elnaz Moslehifard, Mehrnaz Motiei

Journal of Dental Research, Dental Clinics, Dental Prospects.2019; 13(3): 227. CrossRef - Properties of hot-pressed lithium silicate glass-ceramics

Lubica Hallmann, Peter Ulmer, Mark-Daniel Gerngross, Justin Jetter, Michaël Mintrone, Frank Lehmann, Matthias Kern

Dental Materials.2019; 35(5): 713. CrossRef - Enhanced bonding strength between lithium disilicate ceramics and resin cement by multiple surface treatments after thermal cycling

Rui Li, Shi Qing Ma, Cheng Cheng Zang, Wen Yi Zhang, Zi Hao Liu, Ying Chun Sun, Yi Yu Feng, Rafael Sarkis-Onofre

PLOS ONE.2019; 14(7): e0220466. CrossRef - Effect of Two Polishing Systems on Surface Roughness, Topography, and Flexural Strength of a Monolithic Lithium Disilicate Ceramic

Mahshid Mohammadibassir, Mohammad Bagher Rezvani, Hossein Golzari, Elham Moravej Salehi, Mohammad Amin Fahimi, Mohammad Javad Kharazi Fard

Journal of Prosthodontics.2019;[Epub] CrossRef - Translucency, hardness and strength parameters of PMMA resin containing graphene-like material for CAD/CAM restorations

Shruti Vidhawan Agarwalla, Ritika Malhotra, Vinicius Rosa

Journal of the Mechanical Behavior of Biomedical Materials.2019; 100: 103388. CrossRef - Fracture Resistance of Monolithic Glass‐Ceramics Versus Bilayered Zirconia‐Based Restorations

Tamer A. Hamza, Rana M. Sherif

Journal of Prosthodontics.2019;[Epub] CrossRef - Does the Translucency of Novel Monolithic CAD/CAM Materials Affect Resin Cement Polymerization with Different Curing Modes?

Yagmur Ozer Caprak, Pinar Turkoglu, Gokhan Akgungor

Journal of Prosthodontics.2019;[Epub] CrossRef - Evaluation of the ceramic liner bonding effect between zirconia and lithium disilicate

Sung-Hoon Kim, Chan-Jin Park, Lee-Ra Cho, Yoon-Hyuk Huh

The Journal of Prosthetic Dentistry.2018; 120(2): 282. CrossRef - The effect of adhesive failure and defects on the stress distribution in all-ceramic crowns

Yonggang Liu, Yuanzhi Xu, Bo Su, Dwayne Arola, Dongsheng Zhang

Journal of Dentistry.2018; 75: 74. CrossRef - Mechanical and optical properties of monolithic CAD-CAM restorative materials

Nazmiye Sen, Yesim Olcer Us

The Journal of Prosthetic Dentistry.2018; 119(4): 593. CrossRef - Effects of surface treatments on repair bond strength of a new CAD/CAM ZLS glass ceramic and two different types of CAD/CAM ceramics

Ayse Seda Ataol, Gulfem Ergun

Journal of Oral Science.2018; 60(2): 201. CrossRef - Evaluation of the marginal and internal gaps of three different dental prostheses: comparison of the silicone replica technique and three-dimensional superimposition analysis

Jin-Young Park, So-Yeon Bae, Jae-Jun Lee, Ji-Hwan Kim, Hae-Young Kim, Woong-Chul Kim

The Journal of Advanced Prosthodontics.2017; 9(3): 159. CrossRef - Dental ceramics: a review of new materials and processing methods

Lucas Hian da SILVA, Erick de LIMA, Ranulfo Benedito de Paula MIRANDA, Stéphanie Soares FAVERO, Ulrich LOHBAUER, Paulo Francisco CESAR

Brazilian Oral Research.2017;[Epub] CrossRef - Bonding of the silane containing multi-mode universal adhesive for lithium disilicate ceramics

Hyun-Young Lee, Geum-Jun Han, Juhea Chang, Ho-Hyun Son

Restorative Dentistry & Endodontics.2017; 42(2): 95. CrossRef - Tribological behaviour of unveneered and veneered lithium disilicate dental material

C.G. Figueiredo-Pina, N. Patas, J. Canhoto, R. Cláudio, S.M. Olhero, A.P. Serro, A.C. Ferro, M. Guedes

Journal of the Mechanical Behavior of Biomedical Materials.2016; 53: 226. CrossRef - Survival of resin infiltrated ceramics under influence of fatigue

Moustafa N. Aboushelib, Mohamed H. Elsafi

Dental Materials.2016; 32(4): 529. CrossRef - Reliability Analysis of Lithium Disilicate Crowns: Effectof Veneering and Milling Production Workflow

Paolo Cardelli, Nicola Serafini, Bruna Sinjari, Giovanna Murmura, Mutlu Özcan

Journal of Prosthodontics.2016; 25(8): 623. CrossRef - Effects of pretreatments and hydrothermal aging on biaxial flexural strength of lithium di-silicate and Mg-PSZ ceramics

Maria André, Wen Kou, Göran Sjögren, Anders Sundh

Journal of Dentistry.2016; 55: 25. CrossRef - EFFECT OF PRE-CRYSTALLIZATION ON LITHIUM DISILICATE GLASS-CERAMICS FABRICATED BY DIFFERENT PROCESSES

Naruporn Monmaturapoj, Autcharaporn Sri-On, Thossapol Chunkiri

Phosphorus Research Bulletin.2016; 31: 24. CrossRef - Measurement of J-integral in CAD/CAM dental ceramics and composite resin by digital image correlation

Yanxia Jiang, Anna Akkus, Renato Roperto, Ozan Akkus, Bo Li, Lisa Lang, Sorin Teich

Journal of the Mechanical Behavior of Biomedical Materials.2016; 62: 240. CrossRef - The Effect of Hydrofluoric Acid Etching Duration on the Surface Micromorphology, Roughness, and Wettability of Dental Ceramics

Ravikumar Ramakrishnaiah, Abdulaziz Alkheraif, Darshan Divakar, Jukka Matinlinna, Pekka Vallittu

International Journal of Molecular Sciences.2016; 17(6): 822. CrossRef - Fracture resistance of monolithic zirconia molar crowns with reduced thickness

Keisuke Nakamura, Akio Harada, Ryoichi Inagaki, Taro Kanno, Yoshimi Niwano, Percy Milleding, Ulf Örtengren

Acta Odontologica Scandinavica.2015; 73(8): 602. CrossRef - Fracture resistance of computer-aided design and computer-aided manufacturing ceramic crowns cemented on solid abutments

Deborah Stona, Luiz Henrique Burnett, Eduardo Gonçalves Mota, Ana Maria Spohr

The Journal of the American Dental Association.2015; 146(7): 501. CrossRef - Mechanical performance of implant-supported posterior crowns

Paul de Kok, Cornelis J. Kleverlaan, Niek de Jager, Ruud Kuijs, Albert J. Feilzer

The Journal of Prosthetic Dentistry.2015; 114(1): 59. CrossRef - Effect of Thermocycling on Flexural Strength and Weibull Statistics of Machinable Glass–Ceramic and Composite Resin

Chaimongkon Peampring, Sasiwimol Sanohkan

The Journal of Indian Prosthodontic Society.2014; 14(4): 376. CrossRef - The effects of repeated heat-pressing on the mechanical properties and microstructure of IPS e.max Press

Xuehua Tang, Chengzhong Tang, Han Su, Huinan Luo, Takashi Nakamura, Hirofumi Yatani

Journal of the Mechanical Behavior of Biomedical Materials.2014; 40: 390. CrossRef - Flexural strength of a pressable lithium disilicate ceramic: influence of surface treatments

Tabata do Prado Sato, Caroline Cotes, Lígia Tiaki Yamamoto, Natalia Rivoli Rossi, Vanessa da Cruz Macedo, Estevão Tomomitsu Kimpara

Applied Adhesion Science.2013;[Epub] CrossRef

- Lithium silicate glass‐ceramics for dental restoration: From fundamental properties to machine‐learning design

- 5,224 View

- 32 Download

- 81 Crossref

-

Inhibitory effect on

Streptococcus mutans and mechanical properties of the chitosan containing composite resin - Ji-Sun Kim, Dong-Hoon Shin

- Restor Dent Endod 2013;38(1):36-42. Published online February 26, 2013

- DOI: https://doi.org/10.5395/rde.2013.38.1.36

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives This study evaluated the antibacterial effect and mechanical properties of composite resins (LCR, MCR, HCR) incorporating chitosan with three different molecular weights (L, Low; M, Medium; H, High).

Materials and Methods Streptococcus (S). mutans 100 mL and each chitosan powder were inoculated in sterilized 10 mL Brain-Heart Infusion (BHI) solution, and was centrifuged for 12 hr. Absorbance of the supernatent was measured at OD660 to estimate the antibacterial activities of chitosan. AfterS. mutans was inoculated in the disc shaped chitosan-containing composite resins, the disc was cleansed with BHI and diluted with serial dilution method.S. mutans was spread onMitis-salivarius bacitracin agar. After then, colony forming unit (CFU) was measured to verify the inhibitory effect onS. mutans biofilm. To ascertain the effect on the mechanical properties of composite resin, 3-point bending and Vickers hardness tests were done after 1 and 3 wk water storage, respectively. Using 2-way analysis of variance (ANOVA) and Scheffe test, statistical analysis was done with 95% significance level.Results All chitosan powder showed inhibition effect against

S. mutans . CFU number in chitosan-containing composite resins was smaller than that of control resin without chitosan. The chitosan containing composite resins did not show any significant difference in flexural strength and Vickers hardness in comparison with the control resin. However, the composite resin, MCR showed a slightly decreased flexural strength and the maximum load than those of control and the other composite resins HCR and LCR.Conclusions LCR and HCR would be recommended as a feasible antibacterial restorative due to its antibacterial nature and mechanical properties.

-

Citations

Citations to this article as recorded by- Dental Resin Composites Modified with Chitosan: A Systematic Review

Wojciech Dobrzyński, Paweł J. Piszko, Jan Kiryk, Sylwia Kiryk, Mateusz Michalak, Agnieszka Kotela, Julia Kensy, Witold Świenc, Natalia Grychowska, Jacek Matys, Maciej Dobrzyński

Marine Drugs.2025; 23(5): 199. CrossRef - Bactericidal Effects of Ultraviolet-C Light-Emitting Diode Prototype Device Through Thin Optical Fiber

Mi-Jeong Jeon, Yu-Sung Choi, Deog-Gyu Seo

Applied Sciences.2025; 15(8): 4504. CrossRef - Antibacterial activity, cytotoxicity, and microshear bond strength of an experimental adhesive system containing chitosan-based silver oxide particles

Hamideh Sadat Mohammadipour, Alireza Boruziniat, Seyedeh Azam Hoseini, Hosein Bagheri, Navid Ramezanian, Abbas Tanhaieian, Solmaz Pourgonabadi, Arsalan Shahri

Odontology.2025;[Epub] CrossRef - Synthesis and evaluation of a novel antibacterial nanocomposite resin restorative material

Rasha Abd El Rahman El Naggar, Manal A. ElEbiary, ElRefaie Kenawy, Gehan A. Elolimy

Tanta Dental Journal.2025; 22(3): 439. CrossRef - The impact of chitosan in experimental resin with different photoinitiator systems

Isaías Donizeti Silva, Letícia Cristina Cidreira Boaro, Bruno Vilela Muniz, Karina Cogo-Muller, Flávia Gonçalves, William Cunha Brandt

Journal of the Mechanical Behavior of Biomedical Materials.2024; 150: 106323. CrossRef - The effect of adding chitosan nanoparticles on different properties of the adhesive and high-filled composite resin

Mahan Masoumi, Sara Valizadeh, Ricardo M. Carvalho, Alireza Akbari Moghaddam, Safoura Ghodsi

International Journal of Adhesion and Adhesives.2024; 134: 103766. CrossRef - Prospective and applications of bacterial nanocellulose in dentistry

Yasmin Alimardani, Esmaeel Mirzakhani, Fereshteh Ansari, Hadi Pourjafar, Nadia Sadeghi

Cellulose.2024; 31(13): 7819. CrossRef - BNN/TiO2 nanocomposite system–modified dental flow resins and the mechanism of the enhancement of mechanical and antibacterial properties

Xinzi Kong, Qize Han, Axue Jiang, Yurui Wang, Ruizhi Li, Yuting Wang, Shengjie Xiao, Rong Wei, Yu Ma

Biomaterials Science.2023; 11(8): 2775. CrossRef - Influence of the Loading with Newly Green Silver Nanoparticles Synthesized Using Equisetum sylvaticum on the Antibacterial Activity and Surface Hardness of a Composite Resin

Ionuț Tărăboanță, Ana Flavia Burlec, Simona Stoleriu, Andreia Corciovă, Adrian Fifere, Denisa Batir-Marin, Monica Hăncianu, Cornelia Mircea, Irina Nica, Andra Claudia Tărăboanță-Gamen, Sorin Andrian

Journal of Functional Biomaterials.2023; 14(8): 402. CrossRef - The Impact of Adding Chitosan Nanoparticles on Biofilm Formation, Cytotoxicity, and Certain Physical and Mechanical Aspects of Directly Printed Orthodontic Clear Aligners

Botan Barzan Taher, Tara Ali Rasheed

Nanomaterials.2023; 13(19): 2649. CrossRef - Synthesis of Submicrometric Chitosan Particles Loaded with Calcium Phosphate for Biomedical Applications

Diana Pereira Lopes, Selma Regina Muniz Freitas, Carina Baptiston Tanaka, Giovanne Delechiave, Lucia Nobuco Takamori Kikuchi, Roberto R. Braga, Jamie J. Kruzic, Maria Stella Moreira, Leticia Cristina Cidreira Boaro, Luiz Henrique Catalani, Flávia Gonçalve

AAPS PharmSciTech.2023;[Epub] CrossRef - Biodegradable Nonwoven Materials with Antipathogenic Layer

Longina Madej-Kiełbik, Karolina Gzyra-Jagieła, Jagoda Jóźwik-Pruska, Maria Wiśniewskia-Wrona, Marzena Dymel

Environments.2022; 9(7): 79. CrossRef - Comparative evaluation of eighth-generation bonding agent modified with 7% arginine and 0.12% chitosan for antibacterial property and microtensile bond strength

HimaliRajan Desai, SanjyotA Mulay, RonitR Shinde, PradeepK Shetty, SoumyaS Shetty

Journal of Conservative Dentistry.2022; 25(4): 440. CrossRef - Effects of the crosslinking of chitosan/DCPA particles in the antimicrobial and mechanical properties of dental restorative composites

Lucia Nobuco Takamori Kikuchi, Selma Regina Muniz Freitas, Aldo Ferreira Amorim, Giovanne Delechiave, Luiz Henrique Catalani, Roberto Ruggiero Braga, Maria Stella Moreira, Leticia Cristina Cidreira Boaro, Flávia Gonçalves

Dental Materials.2022; 38(9): 1482. CrossRef - Antimicrobial activity of lactoferrin-chitosan-gellan nanoparticles and their influence on strawberry preservation

Larissa G.R. Duarte, Carolina S.F. Picone

Food Research International.2022; 159: 111586. CrossRef - Polyphenol-Enriched Extract of Lacquer Sap Used as a Dentine Primer with Benefits of Improving Collagen Cross-Linking and Antibacterial Functions

Ying Zhao, Xi He, Han Wang, Huimin Wang, Zuosen Shi, Song Zhu, Zhanchen Cui

ACS Biomaterials Science & Engineering.2022; 8(9): 3741. CrossRef - Evaluation of the changes in physical properties and mineral content of enamel exposed to radiation after treating with remineralization agent

Merve Pelin Dur, Neslihan Celik, Nilgun Seven

Clinical Oral Investigations.2022; 26(9): 5673. CrossRef - Evaluation of Immediate and Delayed Microleakage of Class V Cavities Restored with Chitosan-incorporated Composite Resins: An In Vitro Study

Roopa R Nadig, Veena Pai, Arpita Deb

International Journal of Clinical Pediatric Dentistry.2021; 14(5): 621. CrossRef - Evaluation of Microleakage of Micro Hybrid Composite Resins versus Chitosan-Incorporated Composite Resins When Restored in Class V Cavities Using Total Etch and Self-Etch Adhesives

Arpita Deb, Veena Pai, Aesha Akhtar, Roopa R. Nadig

Contemporary Clinical Dentistry.2021; 12(4): 346. CrossRef - Nanomaterials Application in Orthodontics

Wojciech Zakrzewski, Maciej Dobrzynski, Wojciech Dobrzynski, Anna Zawadzka-Knefel, Mateusz Janecki, Karolina Kurek, Adam Lubojanski, Maria Szymonowicz, Zbigniew Rybak, Rafal J. Wiglusz

Nanomaterials.2021; 11(2): 337. CrossRef - Antibacterial Effect on Enterococcus Faecalis and Physical Properties of Chitosan Added Calcium Hydroxide Canal Filling Material

Sol Song, Yu-Jin Kim, Jung-Hwan Lee, Joonhaeng Lee, Jisun Shin, Jongbin Kim

THE JOURNAL OF THE KOREAN ACADEMY OF PEDTATRIC DENTISTRY.2021; 48(2): 198. CrossRef - Antibacterial and Bonding Properties of Universal Adhesive Dental Polymers Doped with Pyrogallol

Naji Kharouf, Ammar Eid, Louis Hardan, Rim Bourgi, Youri Arntz, Hamdi Jmal, Federico Foschi, Salvatore Sauro, Vincent Ball, Youssef Haikel, Davide Mancino

Polymers.2021; 13(10): 1538. CrossRef - Efficacy of chitosan-based chewing gum on reducing salivary S. mutans counts and salivary pH: a randomised clinical trial

Zahra Khamverdi, Fatemeh Farhadian, Salman Khazaei, Maryam Adabi

Acta Odontologica Scandinavica.2021; 79(4): 268. CrossRef - Effect of antiseptic gels in the microbiologic colonization of the suture threads after oral surgery

Samuel Rodríguez Zorrilla, Andrés Blanco Carrión, Abel García García, Pablo Galindo Moreno, Xabier Marichalar Mendía, Rafael Seoane Prado, Antonio J. Pérez Estévez, Mario Pérez-Sayáns

Scientific Reports.2020;[Epub] CrossRef - Evaluating antibacterial and surface mechanical properties of chitosan modified dental resin composites

Shahid Ali, Laila Sangi, Naresh Kumar, Bharat Kumar, Zohaib Khurshid, Muhammad S. Zafar

Technology and Health Care.2020; 28(2): 165. CrossRef - Comparison of antibacterial effects of orthodontic composites containing different nanoparticles on Streptococcus mutans at different times

Soghra Yassaei, Ali Nasr, Hengameh Zandi, Mohammad Nima Motallaei

Dental Press Journal of Orthodontics.2020; 25(2): 52. CrossRef - Development of novel dental restorative composites with dibasic calcium phosphate loaded chitosan fillers

Carina B. Tanaka, Diana P. Lopes, Lucia N.T. Kikuchi, Maria Stella Moreira, Luiz H. Catalani, Roberto R. Braga, Jamie J. Kruzic, Flávia Gonçalves

Dental Materials.2020; 36(4): 551. CrossRef - Effect of iodonium salt and chitosan on the physical and antibacterial properties of experimental infiltrants

Mariana Dias FLOR-RIBEIRO, Talita Signoreti GRAZIANO, Flávio Henrique Baggio AGUIAR, Rafael Nóbrega STIPP, Giselle Maria MARCHI

Brazilian Oral Research.2019;[Epub] CrossRef - Chitosan/Fluoride Nanoparticles for Preventing Dental Caries

Niousha Ebrahimi, Ali Asghar Soleimani, Jamal Rashidiani, Beheshteh Malekafzali, Fatemeh Abedini, Hossein Hosseinkhani

Current Dentistry.2019; 1(1): 61. CrossRef - Physical and chemical properties of model composites containing quaternary ammonium methacrylates

Marina Lermenn Vidal, Guilherme Ferreira Rego, Gil Mendes Viana, Lucio Mendes Cabral, Juliana Primo Basílio Souza, Nick Silikas, Luis Felipe Schneider, Larissa Maria Cavalcante

Dental Materials.2018; 34(1): 143. CrossRef - Chitosan—PRP nanosphere as a growth factors slow releasing device with superior antibacterial capability

Radyum Ikono, Etik Mardliyati, Iis Tentia Agustin, Muhammad Mufarrij Fuad Ulfi, Dimas Andrianto, Uswatun Hasanah, Boy Muchlis Bachtiar, Nofa Mardianingsih, Endang Winiati Bachtiar, Nurwenda Novan Maulana, Nurul Taufiqu Rochman, Li Xianqi, Hideaki Kagami,