Search

- Page Path

- HOME > Search

- The effect of thermocycling on the degree of conversion and mechanical properties of a microhybrid dental resin composite

- Mehrsima Ghavami-Lahiji, Melika Firouzmanesh, Hossein Bagheri, Tahereh S. Jafarzadeh Kashi, Fateme Razazpour, Marjan Behroozibakhsh

- Restor Dent Endod 2018;43(2):e26. Published online April 26, 2018

- DOI: https://doi.org/10.5395/rde.2018.43.e26

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

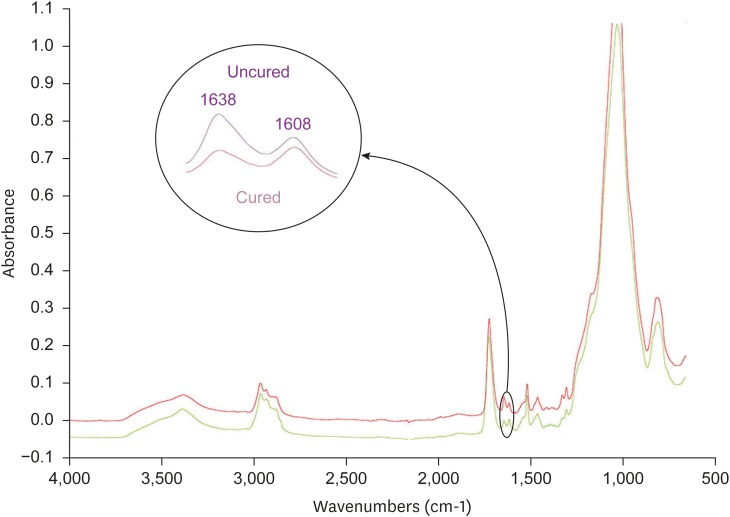

ePub Objective The purpose of this study was to investigate the degree of conversion (DC) and mechanical properties of a microhybrid Filtek Z250 (3M ESPE) resin composite after aging.

Method The specimens were fabricated using circular molds to investigate Vickers microhardness (Vickers hardness number [VHN]) and DC, and were prepared according to ISO 4049 for flexural strength testing. The initial DC (%) of discs was recorded using attenuated total reflectance-Fourier transforming infrared spectroscopy. The initial VHN of the specimens was measured using a microhardness tester under a load of 300 g for 15 seconds and the flexural strength test was carried out with a universal testing machine (crosshead speed, 0.5 mm/min). The specimens were then subjected to thermocycling in 5°C and 55°C water baths. Properties were assessed after 1,000–10,000 cycles of thermocycling. The surfaces were evaluated using scanning electron microscopy (SEM). Data were analyzed using 1-way analysis of variance followed by the Tukey honest significant difference

post hoc test.Results Statistical analysis showed that DC tended to increase up to 4,000 cycles, with no significant changes. VHN and flexural strength values significantly decreased upon thermal cycling when compared to baseline (

p < 0.05). However, there was no significant difference between initial and post-thermocycling VHN results at 1,000 cycles. SEM images after aging showed deteriorative changes in the resin composite surfaces.Conclusions The Z250 microhybrid resin composite showed reduced surface microhardness and flexural strength and increased DC after thermocycling.

-

Citations

Citations to this article as recorded by- Color Stability Under Challenge: Effects of Thermo-Aging and Mouthrinse Exposure on Anterior Teeth and Esthetic Composites

Gökçe Keçeci, Zehra Güner, Süleyman Ziya Şenyurt, Kamile Erciyas

European Journal of Therapeutics.2026; 32(1): 94. CrossRef - Evaluation of surface roughness of PEEK and Laser-Sintered cobalt–chromium subjected to different polishing protocols and thermocycling (an in vitro study)

Marzia Kareem Ahmed, Aras Maruf Rauf

Oxford Open Materials Science.2026;[Epub] CrossRef - Comparative influence of triton and cavity conditioners on the surface characteristics and bond strength of dentin, indicating triton as a cavity conditioner

Lena Bal, Cangül Keskin, Aybüke Karaca Sakallı, Bilge Özcan

Journal of Health Sciences and Medicine.2026; 9(1): 98. CrossRef - The Influence of Thermal and Mechanical Aging on the Flexural Properties of Conventional and 3D-Printed Materials Used in Occlusal Splints Manufacturing

Joanna Smardz, Katarzyna Kresse-Walczak, Heike Meißner, Klaus Böning, Joanna Weżgowiec, Andrzej Małysa, Mieszko Więckiewicz

Materials.2026; 19(2): 421. CrossRef - Failure mechanism analysis and machine learning-based residual strength prediction of CFRP with different ply orientations and loading types under six typical accelerated aging environments

Guofeng Qin, Chenglong Su, Peiwen Mi, Peng Huang, Qiuhan Fan, Ming Li, Wei Tan

Construction and Building Materials.2026; 516: 145630. CrossRef - Discoloration, radiopacity, and push-out bond strength of bismuth-based radiopacifiers in endodontic sealers

Mohammad Ali Saghiri, Mina Shekarian, Amir Abdolmaleki, Michael Conte, Steven M. Morgano

Odontology.2026;[Epub] CrossRef - Clinical Decision‐Making of Repair vs. Replacement of Defective Direct Dental Restorations: A Multinational Cross‐Sectional Study With Meta‐Analysis

Ömer Hatipoğlu, João Filipe Brochado Martins, Mohmed Isaqali Karobari, Nessrin Taha, Thiyezen Abdullah Aldhelai, Daoud M. Ayyad, Ahmed A. Madfa, Benjamin Martin‐Biedma, Rafael Fernández‐Grisales, Bakhyt A. Omarova, Wen Yi Lim, Suha Alfirjani, Kacper Nijak

Journal of Esthetic and Restorative Dentistry.2025; 37(4): 977. CrossRef - An In Vitro Evaluation of Novel Bioactive Liner's Effect on Marginal Adaptation of Class II Composite Restorations: A Scanning Electron Microscope Analysis

Girija S Sajjan, Naveena Ponnada, Praveen Dalavai, Madhu Varma Kanumuri, Venkata Karteek Varma Penmatsa, B V Sindhuja

World Journal of Dentistry.2025; 15(9): 749. CrossRef - Different contemporary resin cements for intracanal luting of glass fiber posts - Bonding and polymerization assessments

Anna Caroliny Detogni, Vitaliano Gomes de Araújo Neto, Caio Felipe de Almeida Nobre, Victor Pinheiro Feitosa, Mário Alexandre Coelho Sinhoreti

International Journal of Adhesion and Adhesives.2025; 138: 103951. CrossRef - Effect of food-simulating liquids and polishing times on the color stability of microhybrid and nanohybrid resin composites

Muhammet Fidan, Nevin Çankaya

Discover Nano.2025;[Epub] CrossRef - Effect of irrigation protocols for post space preparation on the bond of the resin luting agent and post to a hydraulic calcium silicate filled root: An in vitro study

Nuttanun Poeaim, Sirawut Hiran-us, Yanee Tantilertanant

The Journal of Prosthetic Dentistry.2025; 133(4): 1039.e1. CrossRef - Influence of Different Adhesives and Surface Treatments on Shear and Tensile Bond Strength and Microleakage with Micro-CT of Repaired Bulk-Fill Composites

Handan Yıldırım-Işık, Mediha Büyükgöze-Dindar

Polymers.2025; 17(12): 1680. CrossRef - Effect of thermal ageing on physico-mechanical properties and self-healing potential of experimental 3D-printed denture base resin composites

Mariam Raza Syed, Amr Fawzy

Journal of the Mechanical Behavior of Biomedical Materials.2025; 170: 107123. CrossRef - Effects of aging on the physicomechanical, antimicrobial, and cytotoxicity properties of flowable composite resin with strontium-modified phosphate-based glass

Seo-Hyun Kim, Hye-Bin Go, Myung-Jin Lee, Jae-Sung Kwon

Scientific Reports.2025;[Epub] CrossRef - Colour Stability and Optical Properties of Provisional Crowns Fabricated With Milling, 3D Printing, and Direct Technique

Tommaso Rinaldi, Carlos Serrano Granger, Andrea Santamaría Laorden, Jaime Orejas-Perez, Pablo Gómez Cogolludo

International Dental Journal.2025; 75(6): 103932. CrossRef - EVALUATE DEGREE OF CONVERSION OF NEW BIOACTIVE ORTHODONTIC ADHESIVE WITH COLOR CHANGE & FLUORESCENCE PROPERTY

Mohammed Younis, Neam Fakhri Neam Fakhri

BULLETIN OF STOMATOLOGY AND MAXILLOFACIAL SURGERY.2025; : 39. CrossRef - Antibacterial activity and physicochemical properties of light-curable fluoride varnishes containing strontium phosphate-based glass

Na-Yeon Kim, Mi-Sol Ryu, Ji-Min Lee, Soo-Yeon Jeong, Hye-Been Choi, Myung-Jin Lee, Song-Yi Yang

Clinical Oral Investigations.2025;[Epub] CrossRef - Systematic Review of Studies Comparing Microleakage After Restoration With Cention and Conventional Glass Ionomer Cement in Human Extracted Teeth

Rashmi Misra, Mansi Vandekar, Gayatri Pendse, Omkar Bhosale, Pauravi Hegde, Aashaka Vaishnav

Cureus.2025;[Epub] CrossRef - Evaluation of the radiopacity of different universal composite resins aged by thermocycling

Dilber Çölkesen, Alican Kuran, Neslihan Tekçe

Odontology.2025;[Epub] CrossRef - Exploring the sources and routes of micro- and nanoplastics from dental products and materials: their impact on human health - a systematic review

Vidhya Selvaraj, R. Saravanan, N. Raj Vikram, Uma revathi Gopalakrishnan, Ramsamy M

Next Research.2025; 2(4): 100925. CrossRef - Investigation of the mechanical response of MWCNTs infused carbon/glass fiber-based hybrid composites using digital image correlation

Somaiah Chowdary Mallampati, Ujendra Kumar Komal, Paladugu Rakesh, Parthapratim Barman

Construction and Building Materials.2025; 492: 143068. CrossRef - Mechanical, Surface and Physicochemical Properties of Nanozeolite‐Modified 3D Printed Hybrid Ceramics at Varying Concentrations: An In Vitro Study

Ahmed A. Holiel, Yomna M. Ibrahim, Noha Morsy

Journal of Esthetic and Restorative Dentistry.2025;[Epub] CrossRef - Impact of Graphitic Carbon Nitride on Dental Composite’s Mechanical and Antibacterial Properties

Zainab Rafaqat, Saad Liaqat, Ahmed Bari, Warda Khan Yousafzai, Umar Nishan, Sandleen Feroz, Nawshad Muhammad

Journal of Materials Engineering and Performance.2025;[Epub] CrossRef - Exploring the Biological and Chemical Properties of Emerging 3D-Printed Dental Resin Composites Compared to Conventional Light-Cured Materials

Nikola Živković, Stefan Vulović, Miloš Lazarević, Anja Baraba, Aleksandar Jakovljević, Mina Perić, Jelena Mitrić, Aleksandra Milić Lemić

Materials.2025; 18(22): 5170. CrossRef - Awareness of possible complications associated with direct composite restorations: A multinational survey among dentists from 13 countries with meta-analysis

Anna Lehmann, Kacper Nijakowski, Jakub Jankowski, David Donnermeyer, Paulo J. Palma, Milan Drobac, João Filipe Brochado Martins, Fatma Pertek Hatipoğlu, Indira Tulegenova, Muhammad Qasim Javed, Hamad Mohammad Alharkan, Olga Bekjanova, Sylvia Wyzga, Moataz

Journal of Dentistry.2024; 145: 105009. CrossRef - Comparative evaluation of bond strength and color stability of polyetheretherketone and zirconia layered with indirect composite before and after thermocycling: An in vitro study

Pooja Singh, Subhabrata Maiti, Amrutha Shenoy

The Journal of Indian Prosthodontic Society.2024; 24(3): 252. CrossRef - Biaxial flexural strength of hydrothermally aged resin-based materials

Rodrigo Ricci Vivan, Mariana Miranda de Toledo Piza, Bruna de Mello Silva, Thalya Fernanda Horsth Maltarollo, Gustavo Sivieri-Araujo, Murilo Priori Alcalde, Marco Antonio Hungaro Duarte, Estevam Augusto Bonfante, Henrico Badaoui Strazzi-Sahyon

Journal of the Mechanical Behavior of Biomedical Materials.2024; 155: 106568. CrossRef - Comparative Strength Study of Indirect Permanent Restorations: 3D-Printed, Milled, and Conventional Dental Composites

João Paulo Mendes Tribst, Adelheid Veerman, Gabriel Kalil Rocha Pereira, Cornelis Johannes Kleverlaan, Amanda Maria de Oliveira Dal Piva

Clinics and Practice.2024; 14(5): 1940. CrossRef - Influencia del termociclado sobre la estabilidad del color de dos resinas compuestas

//Influence of thermocycling on the color stability of two composite resins

Verónica Lucía Ventrera, María Eugenia Alejandra Barrionuevo

Revista de la Asociación Odontológica Argentina.2024; : 1. CrossRef - Efeito do protocolo de polimento e do armazenamento em meio úmido na variação de cor, massa e rugosidade superficial de resinas compostas

Leonardo Cruz Morais, Mateus Victória Gontijo, Gabriela Rodrigues Pires, Victor de Morais Gomes, Milton Carlos Kuga, Francisco Fernando Massola Filho, Amanda Gonçalves Franco, Alberto Nogueira da Gama Antunes

Cuadernos de Educación y Desarrollo.2024; 16(6): e4556. CrossRef - A comparison of the mechanical properties of 3D-printed, milled, and conventional denture base resin materials

Hyeong-Ju YU, You-Jung KANG, Yeseul PARK, Hoon KIM, Jee-Hwan KIM

Dental Materials Journal.2024; 43(6): 813. CrossRef - Effect of aging and fiber‐reinforcement on color stability, translucency, and microhardness of single‐shade resin composites versus multi‐shade resin composite

Muhammet Fidan, Özhan Yağci

Journal of Esthetic and Restorative Dentistry.2024; 36(4): 632. CrossRef - Impact of Artificial Aging on the Physical and Mechanical Characteristics of Denture Base Materials Fabricated via 3D Printing

Ahmed Altarazi, Julfikar Haider, Abdulaziz Alhotan, Nick Silikas, Hugh Devlin, Weihao Yuan

International Journal of Biomaterials.2024;[Epub] CrossRef - Synthesis, monomer conversion, and mechanical properties of polylysine based dental composites

Saadia Bano Lone, Rabia Zeeshan, Hina Khadim, Muhammad Adnan Khan, Abdul Samad Khan, Anila Asif

Journal of the Mechanical Behavior of Biomedical Materials.2024; 151: 106398. CrossRef - Bond strength and surface roughness assessment of novel antimicrobial polymeric coated dental cement

Ghada Naguib, Hisham Mously, Jumana Mazhar, Ibrahim Alkanfari, Abdulelah Binmahfooz, Mohammed Zahran, Mohamed T. Hamed

Discover Nano.2024;[Epub] CrossRef - Evaluation of microhardness, degree of conversion, and abrasion resistance of nanoglass and multiwalled carbon nanotubes reinforced three‐dimensionally printed denture base resins

Pansai Ashraf Mohamed, Yomna Mohamed Ibrahim, Kenda Ibrahim Hisham Hanno, Mohamed Mahmoud Abdul‐Monem

Journal of Prosthodontics.2024;[Epub] CrossRef - Effect of CAD-CAM block thickness and translucency on the polymerization of luting materials

Bengü Doğu Kaya, Selinsu Öztürk, Ayşe Aslı Şenol, Erkut Kahramanoğlu, Pınar Yılmaz Atalı, Bilge Tarçın

BMC Oral Health.2024;[Epub] CrossRef - Simulation of oral environmental conditions through artificial aging of teeth for the assessment of enamel discoloration in orthodontics

Celal Irgın

BMC Oral Health.2024;[Epub] CrossRef - Do universal adhesive systems affect color coordinates and color change of single-shade resin composites compared with a multi-shade composite?

Muhammet FİDAN, Özhan YAĞCI

Dental Materials Journal.2023; 42(6): 886. CrossRef - Fabrication, Evaluation, and Performance Ranking of Tri-calcium Phosphate and Silica Reinforced Dental Resin Composite Materials

Sonu Saini, Anoj Meena, Ramkumar Yadav, Amar Patnaik

Silicon.2023; 15(18): 8045. CrossRef - Can Modification with Urethane Derivatives or the Addition of an Anti-Hydrolysis Agent Influence the Hydrolytic Stability of Resin Dental Composite?

Agata Szczesio-Wlodarczyk, Izabela M. Barszczewska-Rybarek, Marta W. Chrószcz-Porębska, Karolina Kopacz, Jerzy Sokolowski, Kinga Bociong

International Journal of Molecular Sciences.2023; 24(5): 4336. CrossRef - Effect of veneering material type and thickness ratio on flexural strength of bi-layered PEEK restorations before and after thermal cycling

Ahmed Gouda, Ashraf Sherif, Mennatallah Wahba, Tarek Morsi

Clinical Oral Investigations.2023; 27(6): 2629. CrossRef - 3D printed denture base material: The effect of incorporating TiO2 nanoparticles and artificial ageing on the physical and mechanical properties

Ahmed Altarazi, Julfikar Haider, Abdulaziz Alhotan, Nick Silikas, Hugh Devlin

Dental Materials.2023; 39(12): 1122. CrossRef - Influence of silane coupling agent and aging on the repair bond strength of dental composites

Gustavo Jusué-Esparza, José Alejandro Rivera-Gonzaga, Guillermo Grazioli, Ana Josefina Monjarás-Ávila, J. Eliezer Zamarripa-Calderón, Carlos Enrique Cuevas-Suárez

Journal of Adhesion Science and Technology.2023; 37(5): 913. CrossRef - Degree of conversion of light‐polymerized composite resin in implant prosthesis screw access opening

Se‐Hyun Park, Yoon‐Hyuk Huh, Chan‐Jin Park, Lee‐Ra Cho, Kyung‐Ho Ko

Journal of Prosthodontics.2023; 32(9): 829. CrossRef - Investigation of the effect of matrix-interface formed with silane-based coupling agents on physico-chemical behavior and flow distance of dental composites

Zerin Yeşil Acar, Merve Tunç Koçyiğit, Meltem Asiltürk

Journal of Molecular Liquids.2023; 378: 121600. CrossRef - Evaluation of Water Sorption and Solubility of 3D-Printed, CAD/CAM Milled, and PMMA Denture Base Materials Subjected to Artificial Aging

Mariya Dimitrova, Angelina Vlahova, Ilian Hristov, Rada Kazakova, Bozhana Chuchulska, Stoyan Kazakov, Marta Forte, Vanja Granberg, Giuseppe Barile, Saverio Capodiferro, Massimo Corsalini

Journal of Composites Science.2023; 7(8): 339. CrossRef - Effect of thermocycling on internal microhardness of high and low viscosity bulk fill composite resins in class I cavities

Sâmara Luciana de Andrade LIMA, Lais Lemos CABRAL, Natália Russo CARLOS, Saulo André de Andrade LIMA, Kamila Rosamilia KANTOVITZ, Flávia Lucisano Botelho do AMARAL

RGO - Revista Gaúcha de Odontologia.2023;[Epub] CrossRef - Effects of an Acidic Environment on the Strength and Chemical Changes of Resin-based Composites

S Kang, B-H Cho

Operative Dentistry.2023; 48(4): E81. CrossRef - Influence of compressive forces and aging through thermocycling on the strength of mono incremental dental composite resins

Cristian Roberto Sigcho Romero, Henry Fabricio Mejía Mosquera, Sandra Marcela Quisiguiña Guevara, Yudy Jacqueline Alvarado Aguayo

Bionatura.2023; 8(4): 1. CrossRef - Push-out Bond Strength of Two Fiber Posts in Composite Resin Using Different Types of Silanization

RM Novis, BLT Leon, FMG França, CP Turssi, RT Basting, FLB Amaral

Operative Dentistry.2022; 47(2): 173. CrossRef - Penetration and Adaptation of the Highly Viscous Zinc-Reinforced Glass Ionomer Cement on Contaminated Fissures: An In Vitro Study with SEM Analysis

Galiah AlJefri, Sunil Kotha, Muhannad Murad, Reham Aljudaibi, Fatmah Almotawah, Sreekanth Mallineni

International Journal of Environmental Research and Public Health.2022; 19(10): 6291. CrossRef - Surface Characteristics and Color Stability of Dental PEEK Related to Water Saturation and Thermal Cycling

Liliana Porojan, Flavia Roxana Toma, Mihaela Ionela Bîrdeanu, Roxana Diana Vasiliu, Ion-Dragoș Uțu, Anamaria Matichescu

Polymers.2022; 14(11): 2144. CrossRef - Effects of aging and light-curing unit type on the volume and internal porosity of bulk-fill resin composite restoration

Afnan O. Al-Zain, Elaf A. Alboloshi, Walaa A. Amir, Maryam A. Alghilan, Eliseu A. Münchow

The Saudi Dental Journal.2022; 34(3): 243. CrossRef - An Evaluation of the Hydrolytic Stability of Selected Experimental Dental Matrices and Composites

Agata Szczesio-Wlodarczyk, Karolina Kopacz, Malgorzata Iwona Szynkowska-Jozwik, Jerzy Sokolowski, Kinga Bociong

Materials.2022; 15(14): 5055. CrossRef - Comparison of the Mechanical Properties and Push-out Bond Strength of Self-adhesive and Conventional Resin Cements on Fiber Post Cementation

MR Santi, RBE Lins, BO Sahadi, JR Soto-Montero, LRM Martins

Operative Dentistry.2022; 47(3): 346. CrossRef - Effect of Different Polymerization Times on Color Change, Translucency Parameter, and Surface Hardness of Bulk-Fill Resin Composites

HY Gonder, M Fidan

Nigerian Journal of Clinical Practice.2022; 25(10): 1751. CrossRef - Surface degradation and biofilm formation on hybrid and nanohybrid composites after immersion in different liquids

Gabriela Escamilla-Gómez, Octavio Sánchez-Vargas, Diana M. Escobar-García, Amaury Pozos-Guillén, Norma V. Zavala-Alonso, Mariana Gutiérrez-Sánchez, José E. Pérez-López, Gregorio Sánchez-Balderas, Gabriel F. Romo-Ramírez, Marine Ortiz-Magdaleno

Journal of Oral Science.2022; 64(4): 263. CrossRef - Effects of Different Adhesive Systems and Orthodontic Bracket Material on Enamel Surface Discoloration: An In Vitro Study

Ali Alqerban, Doaa R. M. Ahmed, Ali S. Aljhani, Dalal Almadhi, Amjad AlShahrani, Hussah AlAdwene, Abdulaziz Samran

Applied Sciences.2022; 12(24): 12885. CrossRef - Effects of Immediate Coating on Unset Composite with Different Bonding Agents to Surface Hardness

Nantawan Krajangta, Supissara Ninbanjong, Sunisa Khosook, Kanjana Chaitontuak, Awiruth Klaisiri

European Journal of Dentistry.2022; 16(04): 828. CrossRef - Rational durability of optical properties of chameleon effect of Omnichroma and Essentia composite thermocycled in black dark drinks (in vitro study)

Bassma Abdelhamed, Asmaa Abdel-Hakeem Metwally, Heba A. Shalaby

Bulletin of the National Research Centre.2022;[Epub] CrossRef - Comparative Evaluation of Shear Bond Strength of Nanohybrid Composite Restoration After the Placement of Flowable Compomer and Composite Using the Snowplow Technique

Meghna Dugar, Anuja Ikhar, Pradnya Nikhade, Manoj Chandak, Nidhi Motwani

Cureus.2022;[Epub] CrossRef - The First Step in Standardizing an Artificial Aging Protocol for Dental Composites—Evaluation of Basic Protocols

Agata Szczesio-Wlodarczyk, Magdalena Fronczek, Katarzyna Ranoszek-Soliwoda, Jarosław Grobelny, Jerzy Sokolowski, Kinga Bociong

Molecules.2022; 27(11): 3511. CrossRef - Effect of Different Surface Treatments on the Long‐Term Repair Bond Strength of Aged Methacrylate‐Based Resin Composite Restorations: A Systematic Review and Network Meta‐analysis

Mahdi Hadilou, Amirmohammad Dolatabadi, Morteza Ghojazadeh, Hossein Hosseinifard, Parnian Alizadeh Oskuee, Fatemeh Pournaghi Azar, Victor Feitosa

BioMed Research International.2022;[Epub] CrossRef - Edge chipping resistance of veneering composite resins

Parissa Nassary Zadeh, Bogna Stawarczyk, Rüdiger Hampe, Anja Liebermann, Felicitas Mayinger

Journal of the Mechanical Behavior of Biomedical Materials.2021; 116: 104349. CrossRef - The effect of radiation exposure and storage time on the degree of conversion and flexural strength of different resin composites

Ragia M. Taher, Lamiaa M. Moharam, Amin E. Amin, Mohamed H. Zaazou, Farid S. El-Askary, Mokhtar N. Ibrahim

Bulletin of the National Research Centre.2021;[Epub] CrossRef - Fracture Load of CAD/CAM Fabricated Cantilever Implant-Supported Zirconia Framework: An In Vitro Study

Ibraheem F. Alshiddi, Syed Rashid Habib, Muhammad Sohail Zafar, Salwa Bajunaid, Nawaf Labban, Mohammed Alsarhan

Molecules.2021; 26(8): 2259. CrossRef - A numerical, theoretical and experimental study of the effect of thermocycling on the matrix-filler interface of dental restorative materials

Yoan Boussès, Nathalie Brulat-Bouchard, Pierre-Olivier Bouchard, Yannick Tillier

Dental Materials.2021; 37(5): 772. CrossRef - Impact of polymerization and storage on the degree of conversion and mechanical properties of veneering resin composites

Felicitas MAYINGER, Marcel REYMUS, Anja LIEBERMANN, Marc RICHTER, Patrick KUBRYK, Henning GROẞEKAPPENBERG, Bogna STAWARCZYK

Dental Materials Journal.2021; 40(2): 487. CrossRef - Intrapulpal Concentration of Hydrogen Peroxide of Teeth Restored With Bulk Fill and Conventional Bioactive Composites

DP Silva, BA Resende, M Kury, CB André, CPM Tabchoury, M Giannini, V Cavalli

Operative Dentistry.2021; 46(3): E158. CrossRef - Silane content influences physicochemical properties in nanostructured model composites

Larissa Maria Cavalcante, Lucielle Guimarães Ferraz, Karinne Bueno Antunes, Isadora Martini Garcia, Luis Felipe Jochims Schneider, Fabrício Mezzomo Collares

Dental Materials.2021; 37(2): e85. CrossRef - AĞIZ GARGARALARI VE ANTİSEPTİKLERİNİN FARKLI KOMPOZİT REZİNLERİN RENK STABİLİTESİNE ETKİSİ

Turan Emre KUZU, Özcan KARATAŞ

Atatürk Üniversitesi Diş Hekimliği Fakültesi Dergisi.2021; : 1. CrossRef - Evaluation of Immediate and Delayed Microleakage of Class V Cavities Restored with Chitosan-incorporated Composite Resins: An In Vitro Study

Roopa R Nadig, Veena Pai, Arpita Deb

International Journal of Clinical Pediatric Dentistry.2021; 14(5): 621. CrossRef - Influence of Diode Laser for the Treatment of Dentin Hypersensitivity on Microleakage of Cervical Restorations

Doaa R. M. Ahmed, Diana G. Shaath, Jomana B. Alakeel, Abdulaziz A. Samran, Mona Abbassy

BioMed Research International.2021;[Epub] CrossRef - Ageing of Dental Composites Based on Methacrylate Resins—A Critical Review of the Causes and Method of Assessment

Agata Szczesio-Wlodarczyk, Jerzy Sokolowski, Joanna Kleczewska, Kinga Bociong

Polymers.2020; 12(4): 882. CrossRef - Flexural strength and surface microhardness of materials used for temporary dental disocclusion submitted to thermal cycling: An in vitro study

Tamires Borges de Lima, José Guilherme Neves, Ana Paula Terossi de Godoi, Ana Rosa Costa, Viviane Veroni Degan, Américo Bortolazzo Correr, Heloisa Cristina Valdrighi

International Orthodontics.2020; 18(3): 519. CrossRef - Evaluation of the repair capacities and color stabilities of a resin nanoceramic and hybrid CAD/CAM blocks

Hasibe Sevilay Bahadır, Yusuf Bayraktar

The Journal of Advanced Prosthodontics.2020; 12(3): 140. CrossRef - Effect of Different Surface Treatments of Resin Relined Fiber Posts Cemented With Self-adhesive Resin Cement on Push-out and Microtensile Bond Strength Tests

RV Machry, PE Fontana, TC Bohrer, LF Valandro, OB Kaizer

Operative Dentistry.2020; 45(4): E185. CrossRef - Influences of Successive Exposure to Bleaching and Fluoride Preparations on the Surface Hardness and Roughness of the Aged Resin Composite Restoratives

Khalid M. Abdelaziz, Shugufta Mir, Shafait Ullah Khateeb, Suheel M. Baba, Saud S. Alshahrani, Eman A. Alshahrani, Zahra A. Alsafi

Medicina.2020; 56(9): 476. CrossRef - Fracture Resistance of Lithıum Disilicate, Indirect Resin Composite and Zirconıa by Using Dual Cure Resin Cements

Mohammed BADWAN, Erkut KAHRAMANOĞLU

Clinical and Experimental Health Sciences.2020; 10(4): 435. CrossRef - Effect of Stress-decreasing Resin Thickness as an Intermediate Layer on Fracture Resistance of Class II Composite Restoration: An In Vitro Study

Dennis Dennis, Arwin Leonardy, Trimurni Abidin

World Journal of Dentistry.2020; 11(2): 91. CrossRef - Effect of Thermocycling on Biaxial Flexural Strength of CAD/CAM, Bulk Fill, and Conventional Resin Composite Materials

EB Benalcázar Jalkh, CM Machado, M Gianinni, I Beltramini, MMT Piza, PG Coelho, R Hirata, EA Bonfante

Operative Dentistry.2019; 44(5): E254. CrossRef - Mechanical properties of hybrid computer-aided design/computer-aided manufacturing (CAD/CAM) materials after aging treatments

Hae-Yong Jeong, Hae-Hyoung Lee, Yu-Sung Choi

Ceramics International.2018; 44(16): 19217. CrossRef

- Color Stability Under Challenge: Effects of Thermo-Aging and Mouthrinse Exposure on Anterior Teeth and Esthetic Composites

- 6,897 View

- 59 Download

- 83 Crossref

KACD

KACD

First

First Prev

Prev