Search

- Page Path

- HOME > Search

- Effect of adhesive application method on repair bond strength of composite

- Hee Kyeong Oh, Dong Hoon Shin

- Restor Dent Endod 2021;46(3):e32. Published online June 4, 2021

- DOI: https://doi.org/10.5395/rde.2021.46.e32

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives This study aimed to evaluate the effect of the application method of universal adhesives on the shear bond strength (SBS) of repaired composites, applied with different thicknesses.

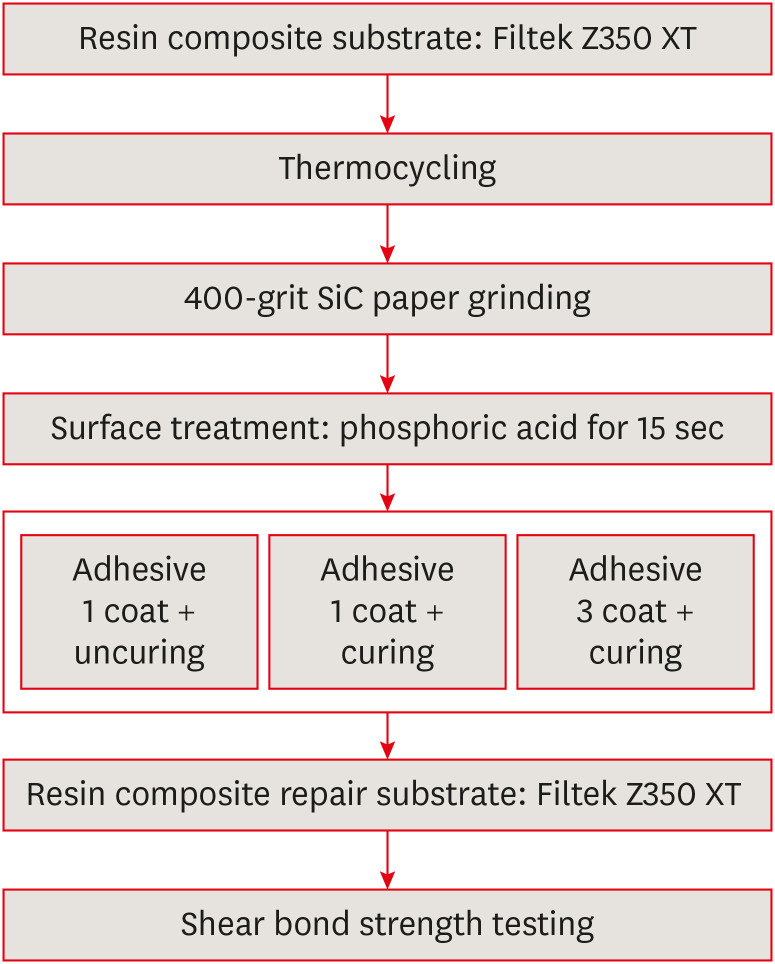

Materials and Methods The 84 specimens (Filtek Z350 XT) were prepared, stored in distilled water for a week and thermocycled (5,000 cycles, 5°C to 55°C). They were roughened using 400-grit sandpapers and etched with phosphoric acid. Then, specimens were equally divided into 2 groups; Single Bond Universal (SU) and Prime&Bond Universal (PB). Each group was subdivided into 3 subgroups according to application methods (

n = 14); UC: 1 coat + uncuring, 1C: 1 coat + curing, 3C: 3 coats + curing. After storage of the repaired composite for 24 hours, specimens were subjected to the SBS test and the data were statistically analyzed by 2-way analysis of variance and independentt -tests. Specimens were examined with a stereomicroscope to analyze fracture mode and a scanning electron microscope to observe the interface.Results Adhesive material was a significant factor (

p = 0.001). Bond strengths with SU were higher than PB. The highest strength was obtained from the 1C group with SU. Bonding in multiple layers increased adhesive thicknesses, but there was no significant difference in SBS values (p = 0.255). Failure mode was predominantly cohesive in old composites.Conclusions The application of an adequate bonding system plays an important role in repairing composite resin. SU showed higher SBS than PB and the additional layers increased the adhesive thickness without affecting SBS.

-

Citations

Citations to this article as recorded by- The effect of different surface treatments and adhesive systems on shear bond strength in universal nanohybrid composite resin repair

Merve Kütük Ömeroğlu, Melek Çam, Işıl Doğruer, Zeynep Buket Kaynar

BMC Oral Health.2025;[Epub] CrossRef - Effect of Universal Adhesive Etching Mode on Shear Bond Strength of Pulp Capping Materials to Deep Dentin

Shahram Amirifar, Saba Tohidkhah, Seyedeh Mahsa Sheikh-Al-Eslamian, Mahdi Abbasi, Fatemeh Farshad, Elham Ahmadi, Carlos M. Ardila

BioMed Research International.2025;[Epub] CrossRef - Shear Bond Strength and Finite Element Stress Analysis of Composite Repair Using Various Adhesive Strategies With and Without Silane Application

Elif Ercan Devrimci, Hande Kemaloglu, Cem Peskersoy, Tijen Pamir, Murat Turkun

Applied Sciences.2025; 15(15): 8159. CrossRef

- The effect of different surface treatments and adhesive systems on shear bond strength in universal nanohybrid composite resin repair

- 3,799 View

- 27 Download

- 3 Web of Science

- 3 Crossref

- The study of fractural behavior of repaired composite

- Sang-Soon Park, Wook Nam, Ah-Hyang Eom, Duck-Su Kim, Gi-Woon Choi, Kyoung-Kyu Choi

- J Korean Acad Conserv Dent 2010;35(6):461-472. Published online November 30, 2010

- DOI: https://doi.org/10.5395/JKACD.2010.35.6.461

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives This study evaluated microtensile bond strength (µTBS) and short-rod fracture toughness to explain fractural behavior of repaired composite restorations according to different surface treatments.

Materials and Methods Thirty composite blocks for µTBS test and sixty short-rod specimens for fracture toughness test were fabricated and were allocated to 3 groups according to the combination of surface treatment (none-treated, sand blasting, bur roughening). Each group was repaired immediately and 2 weeks later. Twenty-four hours later from repair, µTBS and fracture toughness test were conducted. Mean values analyzed with two-way ANOVA / Tukey's B test (α = 0.05) and correlation analysis was done between µTBS and fracture toughness. FE-SEM was employed on fractured surface to examine the crack propagation.

Results The fresh composite resin showed higher µTBS than the aged composite resin (

p < 0.001). Mechanically treated groups showed higher bond strength than non-mechanically treated groups except none-treated fresh group in µTBS (p < 0.05). The fracture toughness value of mechanically treated surface was higher than that of non-mechanically treated surface (p < 0.05). There was no correlation between fracture toughness and microtensile bond strength values. Specimens having high KIC showed toughening mechanism including crack deviation, microcracks and crack bridging in FE-SEM.Conclusions Surface treatment by mechanical interlock is more important for effective composite repair, and the fracture toughness test could be used as an appropriate tool to examine the fractural behavior of the repaired composite with microtensile bond strength.

- 1,021 View

- 1 Download

- The effect of different bonding systems on shear bond strength of repaired composite resin

- Eun-Mi Seon, Hyeon-Cheol Kim, Bock Hur, Jeong-Kil Park

- J Korean Acad Conserv Dent 2008;33(2):125-132. Published online March 31, 2008

- DOI: https://doi.org/10.5395/JKACD.2008.33.2.125

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub The purpose of this study is to compare the shear bond strength of repaired composite resin with different bonding agents and evaluate the effect of bonding agents on composite repair strength. Forty composite specimens (Z-250) were prepared and aged for 1week by thermocycling between 5 and 55℃ with a dwell time of 30s. After air abrasion with 50 µm aluminum oxide, following different bonding agents were applied (n = 10); SB group: Scotchbond multipurpose adhesive (3 step Total-Etch system); SE group: Clearfil SE bond (2 step Self-Etch system); XP group: XP bond (2 step Total-Etch system); XE group: XenoIII (1 step Self-Etch system). After bonding procedure was completed, new composite resin (Z-250) was applied to the mold and cured. For control group, 10 specimens were prepared. Seven days after repair, shear bond strength was measured. Data was statistically analyzed using one-way ANOVA and Tukey's test (p < 0.05). The means and standard deviations of shear bond strength (MPa ± S.D.) per group were as follows: SB group: 17.06; SE group: 19.10; XP group: 14.44; XE group: 13.57; Control Group: 19.40. No significant difference found in each group. Within the limit of this study, it was concluded that the different type of bonding system was not affect on the shear bond strength of repaired composite resin.

-

Citations

Citations to this article as recorded by- Smart Biomaterials: An Evolving Paradigm in Dentistry

Harsha P Rathi, Manoj Chandak, Amit Reche, Abhilasha Dass, Swayangprabha Sarangi, Samiksha R Thawri

Cureus.2023;[Epub] CrossRef

- Smart Biomaterials: An Evolving Paradigm in Dentistry

- 1,518 View

- 7 Download

- 1 Crossref

KACD

KACD

First

First Prev

Prev