Articles

- Page Path

- HOME > Restor Dent Endod > Volume 40(4); 2015 > Article

- Research Article Comparison of mechanical properties of a new fiber reinforced composite and bulk filling composites

- Hazem Abouelleil1, Nelly Pradelle1,2, Cyril Villat1,3, Nina Attik1, Pierre Colon1,2, Brigitte Grosgogeat1,3

-

2015;40(4):-270.

DOI: https://doi.org/10.5395/rde.2015.40.4.262

Published online: September 2, 2015

1Laboratoire des Multimatériaux et Interfaces, UMR CNRS 5615, Université Lyon1, Villeurbanne, France.

2UFR D'odontologie, Université Paris Diderot, APHP, Hôpital Rothschild, Service d'Odontologie, Paris, France.

3UFR Odontologie, Université Lyon1, Service de Consultations et de Traitements Dentaires, Hospices Civils de Lyon, Lyon, France.

- Correspondence to Hazem Abouelleil, DDS, MD. Dental practitioner and Lecturer, Laboratoire des Multimatériaux et Interfaces, UMR CNRS 5615, Université Lyon1, Villeurbanne, France. TEL, +33(0)478778689; FAX, +33(0)478778712; hazem.abouelleilsayed@univ-lyon1.fr

©Copyrights 2015. The Korean Academy of Conservative Dentistry.

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 2,492 Views

- 40 Download

- 66 Crossref

Abstract

-

Objectives The aim of this study was to evaluate the mechanical and physical properties of a newly developed fiber reinforced dental composite.

-

Materials and Methods Fiber reinforced composite EverX Posterior (EXP, GC EUROPE), and other commercially available bulk fill composites, including Filtek Bulk Fill (FB, 3M ESPE), SonicFill (SF, Kerr Corp.), SureFil (SDR, Dentsply), Venus Bulk Fill (VB, HerausKultzer), Tetric evoceram bulk fill (TECB, Ivoclar Vivadent), and Xtra Base (XB, Voco) were characterized. Composite samples light-cured with a LED device were evaluated in terms of flexural strength, flexural modulus (ISO 4049, n = 6), fracture toughness (n = 6), and Vickers hardness (0, 2, and 4 mm in depth at 24 hr, n = 5). The EXP samples and the fracture surface were observed under a scanning electron microscopy. Data were statistically analyzed using one-way ANOVA and unpaired t-test.

-

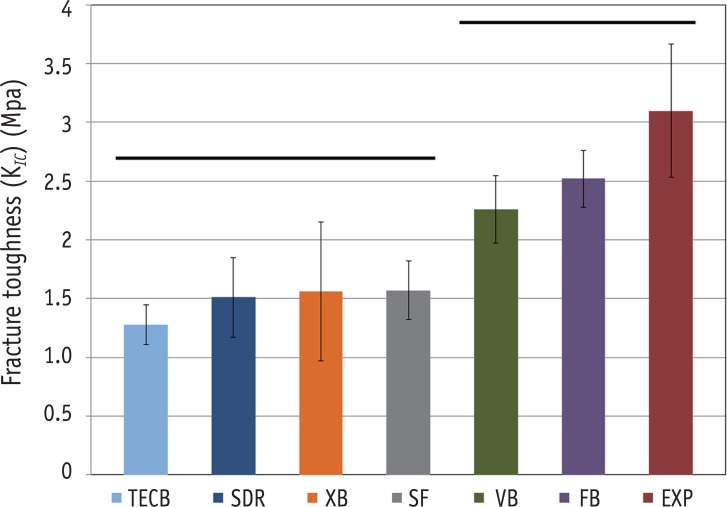

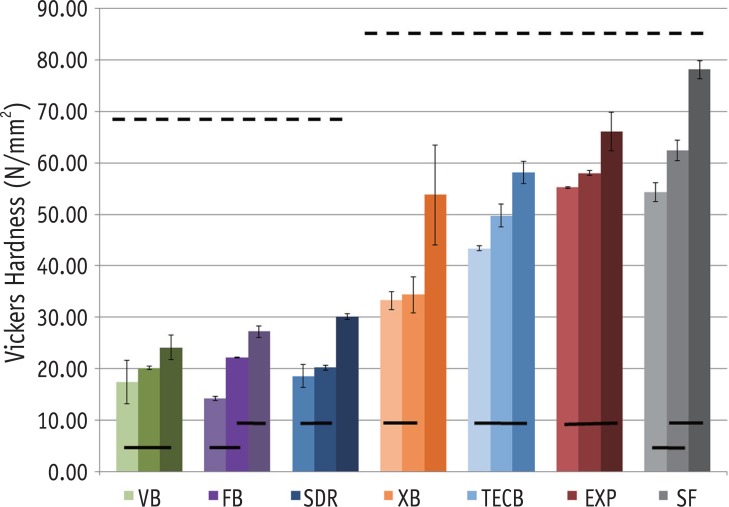

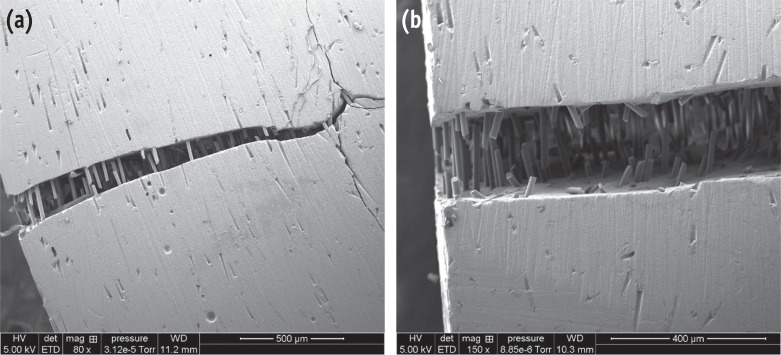

Results EXP, FB, and VB had significantly higher fracture toughness value compared to all the other bulk composite types. SF, EXP, and XB were not statistically different, and had significantly higher flexural strength values compared to other tested composite materials. EXP had the highest flexural modulus, VB had the lowest values. Vickers hardness values revealed SF, EXP, TECB, and XB were not statistically different, and had significantly higher values compared to other tested composite materials. SEM observations show well dispersed fibers working as a reinforcing phase.

-

Conclusions The addition of fibers to methacrylate-based matrix results in composites with either comparable or superior mechanical properties compared to the other bulk fill materials tested.

Introduction

Materials and Methods

Results

Discussion

Conclusions

Acknowledgement

- 1. Pallesen U, van Dijken JW, Halken J, Hallonsten AL, Höigaard R. Longevity of posterior resin composite restorations in permanent teeth in Public Dental Health Service: a prospective 8 years follow up. J Dent 2013;41:297-306.ArticlePubMed

- 2. Demarco FF, Corrêa MB, Cenci MS, Moraes RR, Opdam NJ. Longevity of posterior composite restorations: not only a matter of materials. Dent Mater 2012;28:87-101.ArticlePubMed

- 3. Sarrett DC. Clinical challenges and the relevance of materials testing for posterior composite restorations. Dent Mater 2005;21:9-20.ArticlePubMed

- 4. Cramer NB, Stansbury JW, Bowman CN. Recent advances and developments in composite dental restorative materials. J Dent Res 2011;90:402-416.ArticlePubMedPMCPDF

- 5. Ferracane JL. Resin composite-state of the art. Dent Mater 2011;27:29-38.ArticlePubMed

- 6. Da Rosa Rodolpho PA, Donassollo TA, Cenci MS, Loguércio AD, Moraes RR, Bronkhorst EM, Opdam NJ, Demarco FF. 22-Year clinical evaluation of the performance of two posterior composites with different filler characteristics. Dent Mater 2011;27:955-963.ArticlePubMed

- 7. Walter R. Critical appraisal: bulk-fill flowable composite resins. J Esthet Restor Dent 2013;25:72-76.ArticlePubMedPDF

- 8. Moorthy A, Hogg CH, Dowling AH, Grufferty BF, Benetti AR, Fleming GJ. Cuspal deflection and microleakage in premolar teeth restored with bulk-fill flowable resin-based composite base materials. J Dent 2012;40:500-505.ArticlePubMed

- 9. Ilie N, Bucuta S, Draenert M. Bulk-fill resin-based composites: an in vitro assessment of their mechanical performance. Oper Dent 2013;38:618-625.ArticlePubMedPDF

- 10. Leprince JG, Palin WM, Vanacker J, Sabbagh J, Devaux J, Leloup G. Physico-mechanical characteristics of commercially available bulk-fill composites. J Dent 2014;42:993-1000.ArticlePubMed

- 11. Ilie N, Hickel R, Valceanu AS, Huth KC. Fracture toughness of dental restorative materials. Clin Oral Investig 2012;16:489-498.ArticlePubMedPDF

- 12. El-Safty S, Silikas N, Watts DC. Creep deformation of restorative resin-composites intended for bulk-fill placement. Dent Mater 2012;28:928-935.ArticlePubMed

- 13. Alshali RZ, Silikas N, Satterthwaite JD. Degree of conversion of bulk-fill compared to conventional resin-composites at two time intervals. Dent Mater 2013;29:e213-e217.ArticlePubMed

- 14. Van Ende A, De Munck J, Van Landuyt KL, Poitevin A, Peumans M, Van Meerbeek B. Bulk-filling of high C-factor posterior cavities: effect on adhesion to cavity-bottom dentin. Dent Mater 2013;29:269-277.ArticlePubMed

- 15. Roggendorf MJ, Krämer N, Appelt A, Naumann M, Frankenberger R. Marginal quality of flowable 4-mm base vs. conventionally layered resin composite. J Dent 2011;39:643-647.ArticlePubMed

- 16. Poggio C, Dagna A, Chiesa M, Colombo M, Scribante A. Surface roughness of flowable resin composites eroded by acidic and alcoholic drinks. J Conserv Dent 2012;15:137-140.ArticlePubMedPMC

- 17. Finan L, Palin WM, Moskwa N, McGinley EL, Fleming GJ. The influence of irradiation potential on the degree of conversion and mechanical properties of two bulk-fill flowable RBC base materials. Dent Mater 2013;29:906-912.ArticlePubMed

- 18. Garoushi S, Säilynoja E, Vallittu PK, Lassila L. Physical properties and depth of cure of a new short fiber reinforced composite. Dent Mater 2013;29:835-841.ArticlePubMed

- 19. Heintze SD, Zimmerli B. Relevance of in vitro tests of adhesive and composite dental materials, a review in 3 parts. Part 1: approval requirements and standardized testing of composite materials according to ISO specifications. Schweiz Monatsschr Zahnmed 2011;121:804-816.PubMed

- 20. Alander P, Lassila LV, Vallittu PK. The span length and cross-sectional design affect values of strength. Dent Mater 2005;21:347-353.ArticlePubMed

- 21. Czasch P, Ilie N. In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin Oral Investig 2013;17:227-235.ArticlePubMedPDF

- 22. Xu HH, Schumacher GE, Eichmiller FC, Peterson RC, Antonucci JM, Mueller HJ. Continuous-fiber preform reinforcement of dental resin composite restorations. Dent Mater 2003;19:523-530.ArticlePubMed

- 23. Garoushi S, Vallittu PK, Lassila LV. Short glass fiber reinforced restorative composite resin with semi-inter penetrating polymer network matrix. Dent Mater 2007;23:1356-1362.ArticlePubMed

- 24. Petersen RC. Discontinuous fiber-reinforced composites above critical length. J Dent Res 2005;84:365-370.ArticlePubMedPMCPDF

- 25. Leprince JG, Leveque P, Nysten B, Gallez B, Devaux J, Leloup G. New insight into the "depth of cure" of dimethacrylate-based dental composites. Dent Mater 2012;28:512-520.ArticlePubMed

- 26. Flury S, Hayoz S, Peutzfeldt A, Hüsler J, Lussi A. Depth of cure of resin composites: is the ISO 4049 method suitable for bulk fill materials? Dent Mater 2012;28:521-528.ArticlePubMed

- 27. Galvão MR, Caldas SG, Bagnato VS, de Souza Rastelli AN, de Andrade MF. Evaluation of degree of conversion and hardness of dental composites photo-activated with different light guide tips. Eur J Dent 2013;7:86-93.PubMedPMC

- 28. Polydorou O, Manolakis A, Hellwig E, Hahn P. Evaluation of the curing depth of two translucent composite materials using a halogen and two LED curing units. Clin Oral Investig 2008;12:45-51.ArticlePubMedPDF

- 29. Yap AU, Seneviratne C. Influence of light energy density on effectiveness of composite cure. Oper Dent 2001;26:460-466.PubMed

REFERENCES

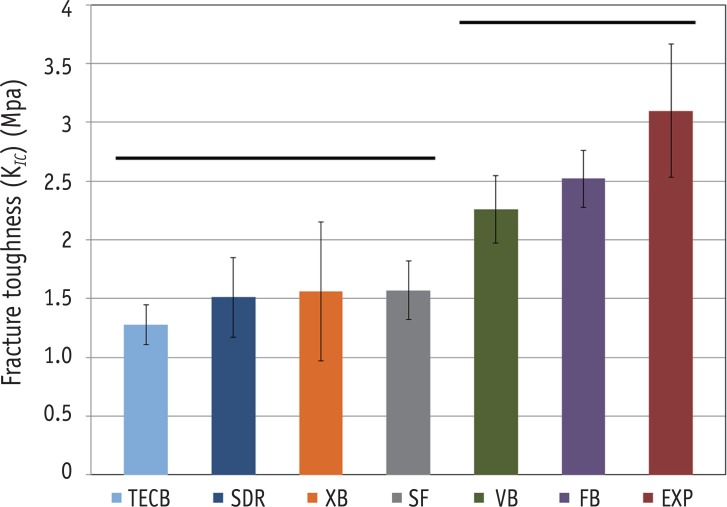

Bar graph illustrating fracture toughness (KIC). Straight line indicates that there was no statistically significant difference between the groups.

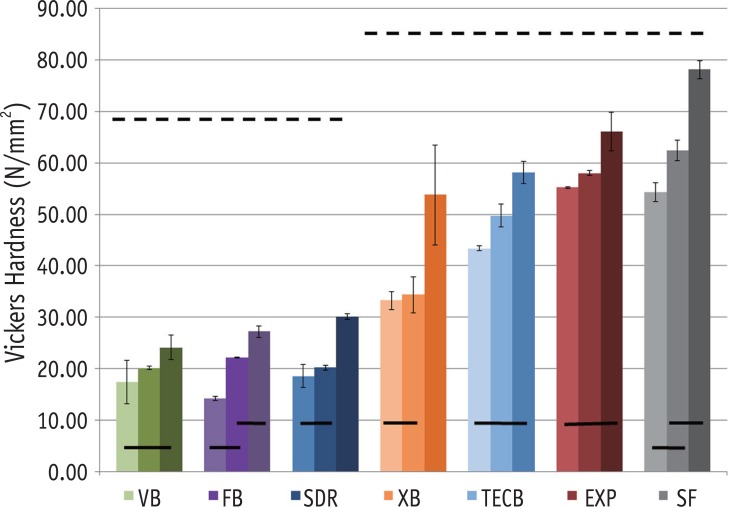

Bar graph illustrating Vickers hardness (N/mm2) at different curing depths of 4 mm, 2 mm and at the surface. Dotted line (-----) indicates that there was no statistically significant difference between the materials. Straight line (——) indicates that there was no statistically significant difference within the same material at different curing depths.

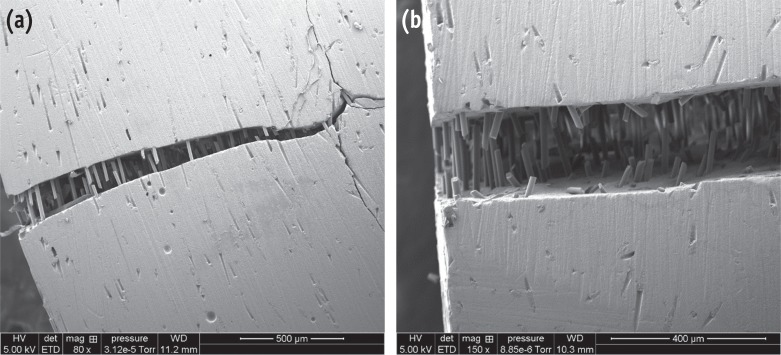

Scanning electron photomicrograph of fracture toughness sample (a) after failure; (b) the fiber orientation across the failure line are shown at higher magnification.

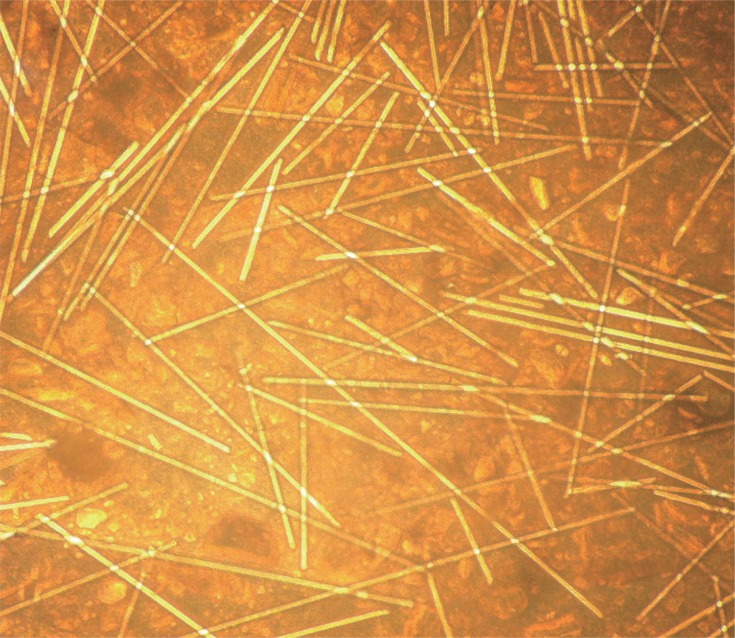

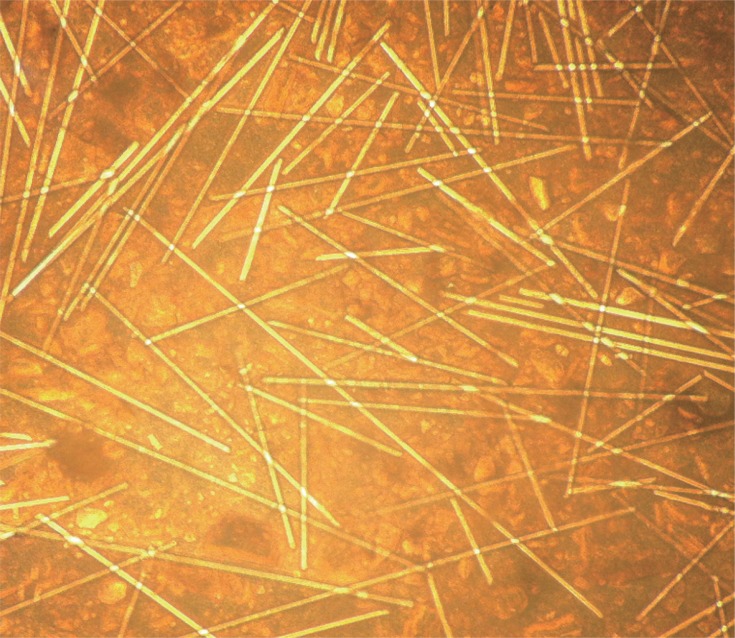

Microscopic image of EverX Posterior showing fiber length extending to the length of one millimeter and up to two milimeters.

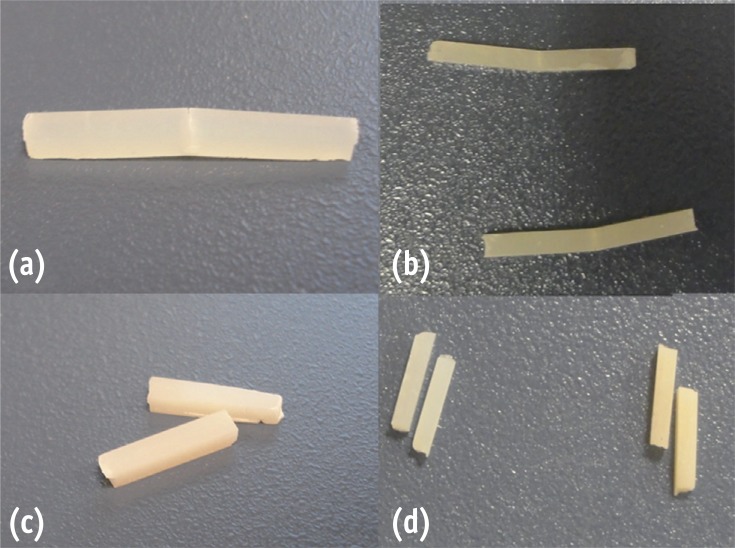

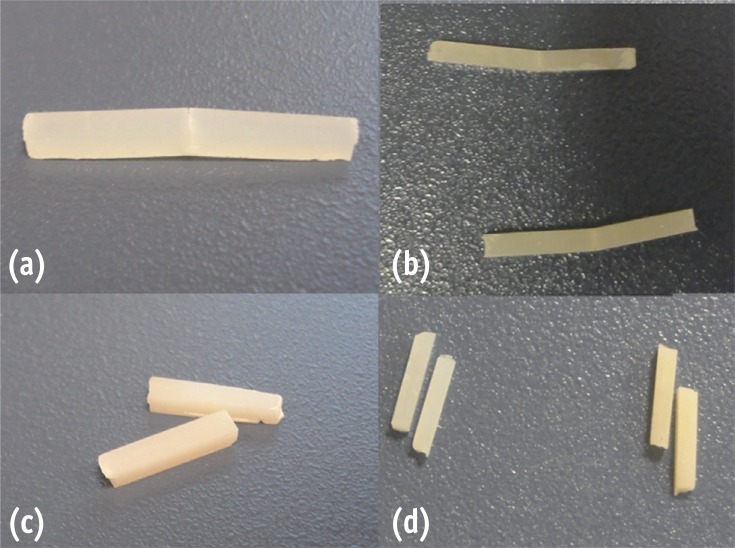

Samples of (a) fracture toughness and (b) flexural strength tests for EverX Posterior remained connected after failure, compared to other bulk composite samples after (c) fracture toughness and (d) flexural strength, which were completely separated into two fragments.

Materials, manufacturers, chemical composition of the matrix, fillers and filler contents

Flexural strength (σ, MPa) and Flexural Modulus (Eflexural, GPa) for the 2 mm and 4 mm sample groups

Tables & Figures

REFERENCES

Citations

- Tailoring the interfacial properties of glass fiber-epoxy microcomposites through the development of a self-healing poly(ϵ-caprolactone) coating

Laura Simonini, Markus Kakkonen, Royson Dsouza, Mikko Kanerva, Haroon Mahmood, Andrea Dorigato, Alessandro Pegoretti

Composites Science and Technology.2025; 261: 110991. CrossRef - Assessing the bond strength of short fiber composites to dentin using various air abrasion particles

Ece Ucar Başol, Isil Cekic-Nagas, Sufyan Garoushi, Emre Nagas, Pekka Kalevi Vallittu, Lippo Veli Juhana Lassila

Journal of Prosthodontic Research.2025; 69(3): 429. CrossRef - Effect of using different materials and restorative techniques on cuspal deflection and microleakage in endodontically treated teeth

Ceyda Sari, Oya Bala, Sinem Akgul, Cemile Kedici Alp

BMC Oral Health.2025;[Epub] CrossRef - Error analysis in bending tests of short specimens and the new accurate formulas for elastic and shear moduli

A. V. Khokhlov

Industrial laboratory. Diagnostics of materials.2025; 91(2): 54. CrossRef - Assessing Toxicological Safety of EverX Posterior and Filtek Ultimate: An In-Depth Extractable and Leachable Study Under ISO 10993-17 and 10993-18 Standards

Aysu Aydınoǧlu, Yelda Erdem Hepşenoǧlu, Can Özgür Yalçın, Kadir Saǧır, Yeşim Ölçer Us, Şeyda Erşahan Eroǧlu, Afife Binnaz Hazar Yoruç

ACS Omega.2025; 10(10): 9903. CrossRef - Poly(butylene adipate-co-terephthalate) as a new healing agent for epoxy/basalt composites

Laura Simonini, Daniele Rigotti, Jeevan Kishore Reddy Pidapa, Alessandro Pegoretti

Composites Part A: Applied Science and Manufacturing.2025; 196: 109010. CrossRef - EFFECT OF DELAMINATION OF LOW SHEAR STRENGTH MATERIALS ON FRACTURE AND TEST RESULTS UNDER THREE-POINT BENDING

A. V. KHOKHLOV, S. N. GALYSHEV, B. I. ATANOV, V. I. ORLOV

Fizicheskaya Mezomekhanika.2025;[Epub] CrossRef - Mechanical and physical evaluation of fiber-reinforced resin composite in comparison with conventional and bulk fill composite

Manal A. El-Ebiary, Enas S. Sadek, Hend Elkafrawy

Tanta Dental Journal.2025; 22(2): 242. CrossRef - Comparison of Commercial and Experimental Fibre-Reinforced Composites in Restoring Endodontically Treated Teeth with Minimal Coronal Dentine: An In Vitro Study

Amre R Atmeh, Faisal Masaud, Luba AlMuhaish, Abdulkarim Alanazi, Hadeel Almutiri, Saqib Ali, Hassan Almoqhawi, Abdul Samad Khan

Journal of Functional Biomaterials.2025; 16(9): 335. CrossRef - Effect of Delamination of Low Shear Strength Materials on Fracture and Test Results under Three-Point Bending

A. V. Khokhlov, S. N. Galyshev, B. I. Atanov, V. I. Orlov

Physical Mesomechanics.2025; 28(4): 439. CrossRef - Evaluation of fracture resistance and crack propensity of bulk-fill composite restorations reinforced by polyethylene fiber

Ayşe Aslı Şenol, Aybike Manav, Bengü Doğu Kaya, Pınar Yılmaz Atalı, Erkut Kahramanoğlu, Bilge Tarçın, Cafer Türkmen

BMC Oral Health.2025;[Epub] CrossRef - A comparison of the effects of incremental and snowplow techniques on the mechanical properties of composite restorations

Y Ölçer Us, A Aydınoğlu, Ş Erşahan, Y Erdem Hepşenoğlu, K Sağır, A Üşümez

Australian Dental Journal.2024; 69(1): 40. CrossRef - Biomimetic approach to strengthen the incisal fracture composite build-up: an in vitro study

Ganesh R. Jadhav, Priya Mittal, Siddharth Shinde, Mohammed A. Al-Qarni, Mohammed Al-Obaid, Shahabe Saquib Abullais, Marco Cicciù, Giuseppe Minervini

BMC Oral Health.2024;[Epub] CrossRef - Mechanical properties and degree of conversion of resin-based core build-up materials and short fiber-reinforced flowable resin-based composite

Abdulrahman ALSHABIB, Carlos A. JURADO, Francisco X. AZPIAZU-FLORES, Khalid ALDOSARY, Akimasa TSUJIMOTO, Hamad ALGAMAIAH

Dental Materials Journal.2024; 43(3): 453. CrossRef - Comparative estimation of fracture resistance of teeth restored with new fiber impregnated composite, short fiber composite, and nanohybrid composite – An in-vitro study

P. Doshi, P. Oswal, S. R. Srinidhi, M. Bhujbal, K. Malu

Endodontics Today.2024; 22(3): 220. CrossRef - Development of Mineral Fillers for Acid-Resistant Filling Composites

Laila M. Kalimoldina, Sandugash O. Abilkasova, Saule O. Akhmetova, Mariya Sh. Suleimenova, Zhanat E. Shaikhova

Journal of Composites Science.2024; 8(7): 284. CrossRef - Fracture resistance of postendodontic restoration using self-adhesive bioactive resin and a bulk-fill composite with or without resin-impregnated glass fibers: An in vitro study

Aishika Paul, Rohit Dubey, Sonal B. Joshi, Anand C. Patil, Pranjali S. Narvekar

Journal of Conservative Dentistry and Endodontics.2024; 27(9): 908. CrossRef - Fracture Toughness of Short Fibre-Reinforced Composites—In Vitro Study

Noor Kamourieh, Maurice Faigenblum, Robert Blizard, Albert Leung, Peter Fine

Materials.2024; 17(21): 5368. CrossRef - Comparative Evaluation of Different Designs of Mesio-occlusal-distal Cavities and Different Composite Systems on Fracture Resistance: An In Vitro Study

Anshul Arora, Vedika Talwar, Sonali Taneja

World Journal of Dentistry.2024; 15(6): 472. CrossRef - Fracture Resistance of Endodontically Treated Tooth Restored with Fiber Reinforced Composite Core and Crown at Different Heights of Ferrule

Saleem D Makandar, Dara Khorsyiah Yakob, Rabihah Alawi, Nor Aidaniza Abdul Muttlib, Normastura Abd Rahman

World Journal of Dentistry.2023; 14(3): 238. CrossRef - Fracture Resistance of Endodontically Treated Teeth Restored With Short Fiber Reinforced Composite and a Low Viscosity Bulk Fill Composite in Class II Mesial-Occlusal-Distal Access Cavities: An Ex-vivo Study

Harish Selvaraj, Jogikalmat Krithikadatta

Cureus.2023;[Epub] CrossRef - Physical Properties and Clinical Performance of Short Fiber Reinforced Resin-based Composite in Posterior Dentition: Systematic Review and Meta-analysis

A Aram, H Hong, C Song, M Bass, JA Platt, S Chutinan

Operative Dentistry.2023; 48(5): E119. CrossRef - Effect of short fiber-reinforced composite combined with polyethylene fibers on fracture resistance of endodontically treated premolars

Sabrina L. Soto-Cadena, Norma V. Zavala-Alonso, Bernardino I. Cerda-Cristerna, Marine Ortiz-Magdaleno

The Journal of Prosthetic Dentistry.2023; 129(4): 598.e1. CrossRef - Systematic review fracture resistance of endodontically treated posterior teeth restored with fiber reinforced composites- a systematic review

Harish Selvaraj, Jogikalmat Krithikadatta, Deepti Shrivastava, Meshal Aber Al Onazi, Hmoud Ali Algarni, Swapna Munaga, May Osman Hamza, Turki saad Al-fridy, Kavalipurapu Venkata Teja, Krishnamachari Janani, Mohammad Khursheed Alam, Kumar Chandan Srivastav

BMC Oral Health.2023;[Epub] CrossRef - Effect of Fibres on Physico-Mechanical Properties of Bulk-Fill Resin Composites

Abdulrahman Alshabib, Nick Silikas, Hamad Algamaiah, Abdullah S. Alayad, Rahaf Alawaji, Shaikha Almogbel, Ahad Aldosari, Abdulaziz Alhotan

Polymers.2023; 15(16): 3452. CrossRef - Shrinkage‐induced cuspal deformation and strength of three different short fiber‐reinforced composite resins

Pascal Magne, Marco Aurelio Carvalho, Taban Milani

Journal of Esthetic and Restorative Dentistry.2023; 35(1): 56. CrossRef - Effects of ceramic thickness, ceramic translucency, and light transmission on light-cured bulk-fill resin composites as luting cement of lithium disilicate based-ceramics

Ting-An Chen, Pei-Ying Lu, Po-Yen Lin, Chih-Wen Chi, Hon Yin Cheng, Yu-Jung Lai, Fajen Wang, Yu-Chih Chiang

Journal of Prosthodontic Research.2023; 68(2): 255. CrossRef - A COMPARATIVE EVALUATION OF COMPRESSIVE STRENGTH AND FLEXURAL STRENGTH OF BULK- FILL RESIN- BASED COMPOSITES: AN INVITRO STUDY

Anindita Saikia, Chandana Kalita, Anija R, Tribisha Kalita, A. C .Bhuyan

INDIAN JOURNAL OF APPLIED RESEARCH.2022; : 62. CrossRef - Comparison of physical and biological properties of a flowable fiber reinforced and bulk filling composites

Nina Attik, Pierre Colon, Rémy Gauthier, Charlène Chevalier, Brigitte Grosgogeat, Hazem Abouelleil

Dental Materials.2022; 38(2): e19. CrossRef - Fracture resistance and flexural strength of endodontically treated teeth restored by different short fiber resin composites: a preclinical study

Wael Gamal, Ahmed Abdou, Ghada A. Salem

Bulletin of the National Research Centre.2022;[Epub] CrossRef - In Vitro Evaluation of the Strength of Dentin Replacement in Complex Posterior Tooth Restoration

Nurhayaty Natsir, Farida Rahim, Juni Jekti Nugroho, Christine Anastasia Rovani, Syamsiah Syam, Muhammad Ruslin, Takashi Saito, Keng-Liang Ou

Applied Sciences.2022; 12(14): 6877. CrossRef - Polymerization Shrinkage of Short Fiber Reinforced Dental Composite Using a Confocal Laser Analysis

Daisuke Miura, Yoshiki Ishida, Akikazu Shinya

Polymers.2021; 13(18): 3088. CrossRef - Comparative Evaluation of Mechanical Properties of Titanium Dioxide Nanoparticle Incorporated in Composite Resin as a Core Restorative Material

Dhanasekaran Sihivahanan, Venugopal V Nandini

The Journal of Contemporary Dental Practice.2021; 22(6): 686. CrossRef - Microtensile Bond Strength, Marginal Leakage, and Antibacterial Effect of Bulk Fill Resin Composite with Alkaline Fillers versus Incremental Nanohybrid Composite Resin

Nada Ismail Mohamed, Rehab Khalil Safy, Ahmed Fawzy Abo Elezz

European Journal of Dentistry.2021; 15(03): 425. CrossRef - The Use of Bulk-Fill Flow in the Customization of Glass Fiber Post

Camila Ferreira Silva, Victor Mota Martins, Anahi de Paula Melo, Laís Carvalho Martins, Paulo Cesar Freitas Santos-Filho

European Journal of Dentistry.2021; 15(01): 139. CrossRef - Comparative Evaluation of Flexural Strength of Two Newer Composite Resin Materials: An in Vitro Study

Akshata Patil, Shashi Rashmi Acharya, Kishore Ginjupalli

Pesquisa Brasileira em Odontopediatria e Clínica Integrada.2021;[Epub] CrossRef - Analysis of marginal integrity in dentistry composite fillings with flow layer under compression test

Monika Ostapiuk, Janusz Tarczydło, Iwona Łuszczewska‐Sierakowska, Radosław Śledź, Barbara Tymczyna‐Borowicz

Microscopy Research and Technique.2021; 84(7): 1442. CrossRef - Effect of the incorporation of silica blow spun nanofibers containing silver nanoparticles (SiO2/Ag) on the mechanical, physicochemical, and biological properties of a low-viscosity bulk-fill composite resin

Soraya Salmanzadeh Ardestani, Roberta Ferreti Bonan, Mariaugusta Ferreira Mota, Rosiane Maria da Costa Farias, Romualdo Rodrigues Menezes, Paulo Rogério Ferreti Bonan, Panmella Pereira Maciel, Flávia Maria de Moraes Ramos-Perez, André Ulisses Dantas Batis

Dental Materials.2021; 37(10): 1615. CrossRef - An in vitro investigation on the reinforcing potential of contemporary composites in weakened bicuspids

ApurvaRamchandra Kale, Shishir Singh, Rajesh Podar, Mohan Kumar, Padmini Chandrasekhar, Gaurav Kulkarni

Journal of Conservative Dentistry.2021; 24(6): 589. CrossRef - Fracture strength of endodontically treated teeth restored with different fiber post and core systems

Taha Özyürek, Can Topkara, İmran Koçak, Koray Yılmaz, Mustafa Gündoğar, Gülşah Uslu

Odontology.2020; 108(4): 588. CrossRef - Comparative evaluation of the surface hardness of different esthetic restorative materials: An in vitro study

Anoop Samuel, Rinsa Raju, KB Sreejith, BinithaM Kalathil, Deepthi Nenavath, VS Chaitra

Journal of Pharmacy And Bioallied Sciences.2020; 12(5): 124. CrossRef - Restoration of a Nonvital Tooth with Fiber Reinforce Composite (Wallpapering Technique)

Sara Valizadeh, Ladan Ranjbar Omrani, Simone Deliperi, Farzaneh Sadeghi Mahounak, Ali I. Abdalla

Case Reports in Dentistry.2020;[Epub] CrossRef - Cracked Tooth Syndrome Management Part 2: Integrating the Old with the New

Oliver Bailey

Dental Update.2020; 47(7): 570. CrossRef - Synthesis and characterization of bioactive glass fiber-based dental restorative composite

Mariam Raza Syed, Nida Zehra Bano, Sarah Ghafoor, Hina Khalid, Shahreen Zahid, Usama Siddiqui, Abbas Saeed Hakeem, Anila Asif, Muhammad Kaleem, Abdul Samad Khan

Ceramics International.2020; 46(13): 21623. CrossRef - Performance of fibre reinforced composite as a post-endodontic restoration on different endodontic cavity designs— an in-vitro study

Sriprakash Shah, D.P. Shilpa-Jain, Natanasabapathy Velmurugan, Chandrasekaran Sooriaprakas, Jogikalmat Krithikadatta

Journal of the Mechanical Behavior of Biomedical Materials.2020; 104: 103650. CrossRef - Influence of Bulk-fill Restoration on Polymerization Shrinkage Stress and Marginal Gap Formation in Class V Restorations

AMO Correia, MR Andrade, JPM Tribst, ALS Borges, TMF Caneppele

Operative Dentistry.2020; 45(4): E207. CrossRef - BULK-FİLL KOMPOZİTLERDE KALINLIĞIN ARTIŞININ MİKROSERTLİK ÜZERİNE ETKİSİ

Evrim ELİGÜZELOĞLU DALKILIÇ, Fehime ALKAN, Hacer DENİZ ARISU

Selcuk Dental Journal.2020; 7(2): 141. CrossRef - Hardness and fracture toughness of resin-composite materials with and without fibers

Abdulrahman Alshabib, Nick Silikas, David C. Watts

Dental Materials.2019; 35(8): 1194. CrossRef - Effect of interface surface design on the fracture behavior of bilayered composites

Tarek A. Omran, Sufyan Garoushi, Lippo V. Lassila, Pekka K. Vallittu

European Journal of Oral Sciences.2019; 127(3): 276. CrossRef - Bonding interface affects the load-bearing capacity of bilayered composites

Tarek A. OMRAN, Sufyan GAROUSHI, Lippo LASSILA, Akikazu SHINYA, Pekka K. VALLITTU

Dental Materials Journal.2019; 38(6): 1002. CrossRef - Properties of a New Nanofiber Restorative Composite

EM Yancey, W Lien, CS Nuttall, JA Brewster, HW Roberts, KS Vandewalle

Operative Dentistry.2019; 44(1): 34. CrossRef - Comparison of the fracture resistance of three different recent composite systems in large Class II mesio-occlusal distal cavities: An in vitro study

YajuvenderSingh Hada, Sumita Panwar

Journal of Conservative Dentistry.2019; 22(3): 287. CrossRef - Physicomechanical and thermal analysis of bulk-fill and conventional composites

Armiliana Soares NASCIMENTO, José Filipe Bacalhau RODRIGUES, Rodolfo Henrique Nogueira TORRES, Kleilton Oliveira SANTOS, Marcus Vinicius Lia FOOK, Monica Soares de ALBUQUERQUE, Eliane Alves de LIMA, Pedro Tardelly Diniz FILGUEIRA, João Batista Morais dos

Brazilian Oral Research.2019;[Epub] CrossRef - Fracture Resistance of Various Bulk-fill Composite Resins in Class II MOD Cavity on Premolars: An In Vitro Study

Wandania Farahanny, Desilia Sihombing

World Journal of Dentistry.2019; 10(3): 166. CrossRef - Physicochemical properties of discontinuous S2-glass fiber reinforced resin composite

Qiting HUANG, Wei QIN, Sufyan GAROUSHI, Jingwei HE, Zhengmei LIN, Fang LIU, Pekka K. VALLITTU, Lippo V. J. LASSILA

Dental Materials Journal.2018; 37(1): 95. CrossRef - Load-bearing capacity of novel resin-based fixed dental prosthesis materials

Isil CEKIC-NAGAS, Ferhan EGILMEZ, Gulfem ERGUN, Pekka Kalevi VALLITTU, Lippo Veli Juhana LASSILA

Dental Materials Journal.2018; 37(1): 49. CrossRef - Structural and mechanical properties of a giomer-based bulk fill restorative in different curing conditions

Mustafa Sarp Kaya, Meltem Bakkal, Ali Durmus, Zehra Durmus

Journal of Applied Oral Science.2018;[Epub] CrossRef - Short fiber‐reinforced composite restorations: A review of the current literature

Sufyan Garoushi, Ausama Gargoum, Pekka K. Vallittu, Lippo Lassila

Journal of Investigative and Clinical Dentistry.2018;[Epub] CrossRef - Optimization of large MOD restorations: Composite resin inlays vs. short fiber-reinforced direct restorations

Luciana Mara Soares, Mehrdad Razaghy, Pascal Magne

Dental Materials.2018; 34(4): 587. CrossRef - A comparative study of bulk-fill composites: degree of conversion, post-gel shrinkage and cytotoxicity

Flávia Gonçalves, Luiza Mello de Paiva Campos, Ezequias Costa Rodrigues-Júnior, Fabrícia Viana Costa, Pamela Adeline Marques, Carlos Eduardo Francci, Roberto Ruggiero Braga, Letícia Cristina Cidreira Boaro

Brazilian Oral Research.2018;[Epub] CrossRef - Spot-Bonding and Full-Bonding Techniques for Fiber Reinforced Composite (FRC) and Metallic Retainers

Andrea Scribante, Paola Gandini, Paola Tessera, Pekka Vallittu, Lippo Lassila, Maria Sfondrini

International Journal of Molecular Sciences.2017; 18(10): 2096. CrossRef - Bond strength of fiber posts and short fiber-reinforced composite to root canal dentin following cyclic loading

Emre Nagas, Isil Cekic-Nagas, Ferhan Egilmez, Gulfem Ergun, Pekka K. Vallittu, Lippo V. J. Lassila

Journal of Adhesion Science and Technology.2017; 31(13): 1397. CrossRef - Fracture resistance of endodontically treated teeth restored with short fiber composite used as a core material—An in vitro study

Tejesh Gupta Garlapati, Jogikalmat Krithikadatta, Velmurugan Natanasabapathy

Journal of Prosthodontic Research.2017; 61(4): 464. CrossRef - Mechanical and structural characterization of discontinuous fiber-reinforced dental resin composite

Jasmina Bijelic-Donova, Sufyan Garoushi, Lippo V.J. Lassila, Filip Keulemans, Pekka K. Vallittu

Journal of Dentistry.2016; 52: 70. CrossRef - Letter to the Editor, “Dentin Bonding Testing Using a Mini-interfacial Fracture Toughness Approach”

N.D. Ruse

Journal of Dental Research.2016; 95(8): 953. CrossRef - Evaluation of Shear Bond Strength of Fiber-reinforced Composite and Methacrylate-based Composite to Pure Tricalcium-based Cement

Ravula A Reddy, RS Basavanna

CODS Journal of Dentistry.2016; 8(1): 25. CrossRef

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Materials, manufacturers, chemical composition of the matrix, fillers and filler contents

| Material | Code name | Manufacturer | Resin matrix | Inorganic filler | Lot |

|---|---|---|---|---|---|

| X-tra base | XB | Voco, Cuxhaven, Germany | Bis-EMA, MMA | 75 wt%, 58 vol% silica | 1305261 |

| Venus Bulk Fill | VB | HerausKultzer, Hanau, Germany | UDMA, EBADMA | 65 wt%, 38 vol% Barium silicate glass and silica | 100325 |

| Filtek Bulk Fill | FB | 3M ESPE, St. Paul, MN, USA | Bis-GMA, Bis-EMA, UDMA | 64 wt%, 42 vol% Zirconia | N414680 |

| Surefil SDR | SDR | Dentsply, Milford, DE, USA | TEGDMA, EBADMA | 68 wt%, 44 vol%, Barium borosilicate glass | 1202174 |

| Tetric EvoCeram Bulk Fill | TECB | Ivoclar Vivadent AG, Schaan, Liechtenstein | Bis-GMA, UDMA, Bis-EMA | 80 wt%, 61 vol% Barium glass filler | S01118 |

| SonicFill | SF | Kerr Corp., Orange, CA, USA | Bis-GMA, Bis-EMA, TEGDMA | 83 vol% Filler | 4252491 |

| EverX Posterior | EXP | GC EUROPE N.V., Leuven, Belgium | Bis-GMA, PMMA, TEGDMA | 74.2 wt%, 53.6 vol% Short E-glass fiber filler, barium glass | 1212261 |

Bis-EMA, ethoxylatedbisphenol A dimethacrylate; MMA, methylmethacrylate; UDMA, urethane dimethacrylate; EBADMA, ethoxylatedbisphenol A dimethacrylate; Bis-GMA, bisphenylglycidyldimethacrylate; TEGDMA, triethylene glycol dimethacrylate; PMMA, polymethyl methacrylate.

Flexural strength (σ, MPa) and Flexural Modulus (Eflexural, GPa) for the 2 mm and 4 mm sample groups

| Flexural strength (σ, MPa) | Flexural Modulus (Eflexural, GPa) | |||

|---|---|---|---|---|

| 2 mm | 4 mm | 2 mm | 4 mm | |

| SonicFill | 157 ± 16K | 147 ± 20k | 12.4 ± 1.6A | 6.5 ± 0.5a* |

| EverX Posterior | 153 ± 9K | 140 ± 14kl | 14.6 ± 1.6A | 6.9 ± 0.5a* |

| X-tra base | 150 ± 8K | 124 ± 13lm | 10.7 ± 1.3A | 5.7 ± 0.4b* |

| Filtek bulk fill | 139 ± 9KL | 139 ± 9kl | 6.3 ± 0.4B | 4.0 ± 0.1c* |

| Surefil SDR | 129 ± 13LM | 121 ± 19lm | 7.2 ± 1.2B | 3.9 ± 0.4c* |

| Tetric evoceram bulk fill | 118 ± 11L | 112 ± 26l | 10.8 ± 0.6A | 5.6 ± 0.2b* |

| Venus bulk fill | 116 ± 5L | 121 ± 10l | 5.0 ± 0.4B | 2.8 ± 0.2d* |

Uppercase letters identify statistically homogenous groups for 2 mm thickness samples. Lower case letters identify statistically homogenous groups for 4 mm thickness samples. Asterisks identify statistical difference between 2 mm and 4 mm thickness samples of the same material (p < 0.05).

Bis-EMA, ethoxylatedbisphenol A dimethacrylate; MMA, methylmethacrylate; UDMA, urethane dimethacrylate; EBADMA, ethoxylatedbisphenol A dimethacrylate; Bis-GMA, bisphenylglycidyldimethacrylate; TEGDMA, triethylene glycol dimethacrylate; PMMA, polymethyl methacrylate.

Uppercase letters identify statistically homogenous groups for 2 mm thickness samples. Lower case letters identify statistically homogenous groups for 4 mm thickness samples. Asterisks identify statistical difference between 2 mm and 4 mm thickness samples of the same material (

KACD

KACD

ePub Link

ePub Link Cite

Cite