Articles

- Page Path

- HOME > Restor Dent Endod > Volume 40(2); 2015 > Article

- Research Article Effect of resin thickness on the microhardness and optical properties of bulk-fill resin composites

-

Eun-Ha Kim1, Kyoung-Hwa Jung1, Sung-Ae Son1, Bock Hur1, Yong-Hoon Kwon2, Jeong-Kil Park1

-

2015;40(2):-135.

DOI: https://doi.org/10.5395/rde.2015.40.2.128

Published online: January 13, 2015

1Department of Conservative Dentistry, School of Dentistry, Pusan National University, Yangsan, Korea.

2Department of Dental Materials, School of Dentistry, Pusan National University, Yangsan, Korea.

- Correspondence to Jeong-Kil Park, DDS, MSD, PhD. Associate Professor, Department of Conservative Dentistry, School of Dentistry, Pusan National University, 20, Geumo-ro, Mulgeum-eup, Yangsan, Korea 626-787. TEL, +82-55-360-5221; FAX, +82-55-360-5214; jeongkil@pusan.ac.kr

©Copyrights 2015. The Korean Academy of Conservative Dentistry.

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0/) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

- 2,096 Views

- 18 Download

- 63 Crossref

Abstract

-

Objectives This study evaluated the effects of the resin thickness on the microhardness and optical properties of bulk-fill resin composites.

-

Methods Four bulk-fill (Venus Bulk Fill, Heraeus Kulzer; SDR, Dentsply Caulk; Tetric N-Ceram Bulk Fill, Ivoclar vivadent; SonicFill, Kerr) and two regular resin composites (Charisma flow, Heraeus Kulzer; Tetric N-Ceram, Ivoclar vivadent) were used. Sixty acrylic cylindrical molds were prepared for each thickness (2, 3 and 4 mm). The molds were divided into six groups for resin composites. The microhardness was measured on the top and bottom surfaces, and the colors were measured using Commission Internationale d'Eclairage (CIE) L*a*b* system. Color differences according to the thickness and translucency parameters and the correlations between the microhardness and translucency parameter were analyzed. The microhardness and color differences were analyzed by ANOVA and Scheffe's post hoc test, and a student t-test, respectively. The level of significance was set to α = 0.05.

-

Results The microhardness decreased with increasing resin thickness. The bulk-fill resin composites showed a bottom/top hardness ratio of almost 80% or more in 4 mm thick specimens. The highest translucency parameter was observed in Venus Bulk Fill. All resin composites used in this study except for Venus Bulk Fill showed linear correlations between the microhardness and translucency parameter according to the thickness.

-

Conclusions Within the limitations of this study, the bulk-fill resin composites used in this study can be placed and cured properly in the 4 mm bulk.

Introduction

Materials and Methods

Results

Discussion

Conclusions

- 1. Lassila LV, Nagas E, Vallittu PK, Garoushi S. Translucency of flowable bulk-filling composites of various thickness. Chin J Dent Res 2012;15:31-35.PubMed

- 2. Ilie N, Bucuta S, Draenert M. Bulk-fill resin-based composites: an in vitro assessment of their mechanical performance. Oper Dent 2013;38:618-625.ArticlePubMedPDF

- 3. Czasch P, Ilie N. In vitro comparison of mechanical properties and degree of cure of bulk fill composites. Clin Oral Investig 2013;17:227-235.ArticlePubMedPDF

- 4. Ilie N, Keßler A, Durner J. Influence of various irradiation processes on the mechanical properties and polymerisation kinetics of bulk-fill resin based composites. J Dent 2013;41:695-702.ArticlePubMed

- 5. Flury S, Hayoz S, Peutzfeldt A, Hüsler J, Lussi A. Depth of cure of resin composites: is the ISO 4049 method suitable for bulk fill materials? Dent Mater 2012;28:521-528.ArticlePubMed

- 6. Tanthanuch S, Ruenqsri P, Kukiattrakoon B. Optimal depth of cure for nanohybrid resin composite using quartz tungsten halogen and new high intensity lightemitting diode curing units. Gen Dent 2013;61:e14-e17.

- 7. Finan L, Palin WM, Moskwa N, McGinley EL, Fleming GJ. The influence of irradiation potential on the degree of conversion and mechanical properties of two bulk-fill flowable resin composite base materials. Dent Mater 2013;29:906-912.PubMed

- 8. Price RB, Dérand T, Loney RW, Andreou P. Effect of light source and specimen thickness on the surface hardness of resin composites. Am J Dent 2002;15:47-53.PubMed

- 9. Ilie N, Hickel R. Investigations on a methacrylate-based flowable composite based on the SDR™ technology. Dent Mater 2011;27:348-355.ArticlePubMed

- 10. Bouschlicher MR, Rueggeberg FA, Wilson BM. Correlation of bottom-to-top surface microhardness and conversion ratios for a variety of resin composite compositions. Oper Dent 2004;29:698-704.PubMed

- 11. Moore BK, Platt JA, Borges G, Chu TM, Katsilieri I. Depth of cure of dental resin composites: ISO 4049 depth and microhardness of types of materials and shades. Oper Dent 2008;33:408-412.ArticlePubMedPDF

- 12. Yeh CL, Powers JM, Miyagawa Y. Color of selected shades of composites by reflection spectrophotometry. J Dent Res 1982;61:1176-1179.ArticlePubMedPDF

- 13. Inokoshi S, Burrow MF, Kataumi M, Yamada T, Takatsu T. Opacity and color changes of tooth-colored restorative materials. Oper Dent 1996;21:73-80.PubMed

- 14. Miyagawa Y, Powers JM, O'Brien WJ. Optical properties of direct restorative materials. J Dent Res 1981;60:890-894.ArticlePubMedPDF

- 15. Johnston WM, Reisbick MH. Color and translucency changes during and after curing of esthetic restorative materials. Dent Mater 1997;13:89-97.ArticlePubMed

- 16. Kim IJ, Lee YK. Changes in color and color parameters of dental resin composites after polymerization. J Biomed Mater Res B Appl Biomater 2007;80:541-546.ArticlePubMed

- 17. Lee YK. Influence of filler on the difference between the transmitted and reflected colors of experimental resin composites. Dent Mater 2008;24:1243-1247.ArticlePubMed

- 18. Campbell PM, Johnston WM, O'Brien WJ. Light scattering and gloss of an experimental quartz-filled composite. J Dent Res 1986;65:892-894.ArticlePubMedPDF

- 19. Kim SJ, Son HH, Cho BH, Lee IB, Um CM. Translucency and masking ability of various opaque-shade composite resins. J Dent 2009;37:102-107.ArticlePubMed

REFERENCES

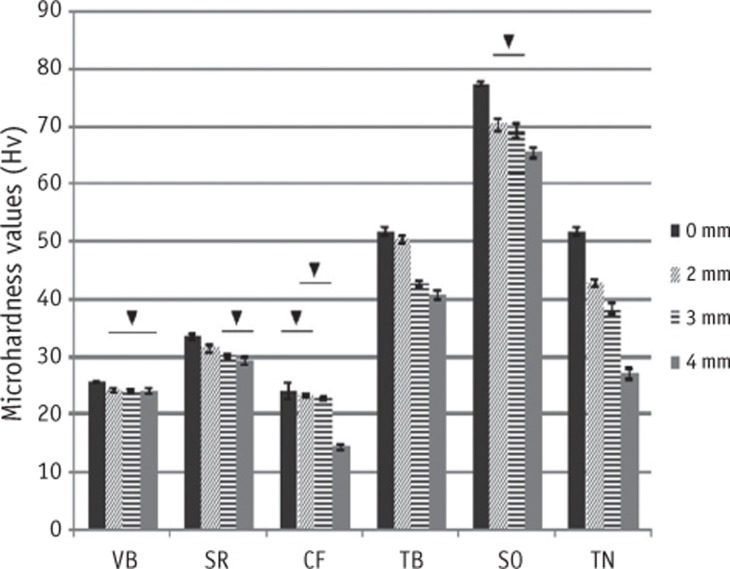

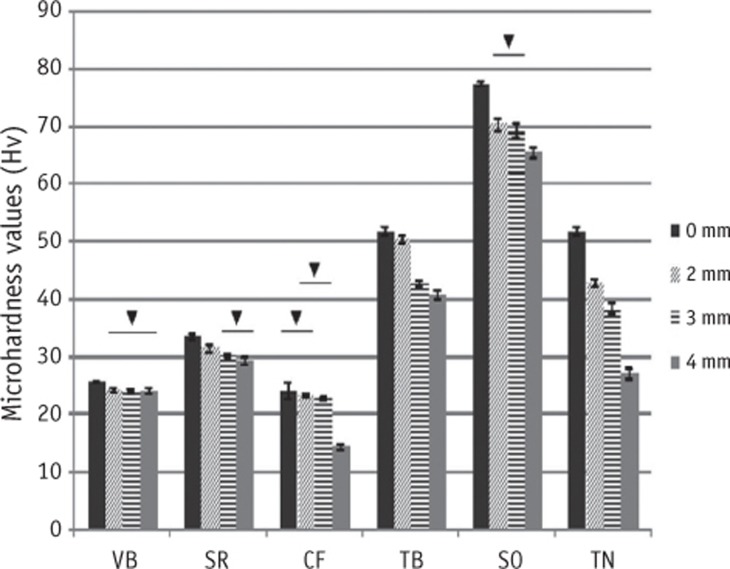

Comparison of microhardness among different thicknesses.

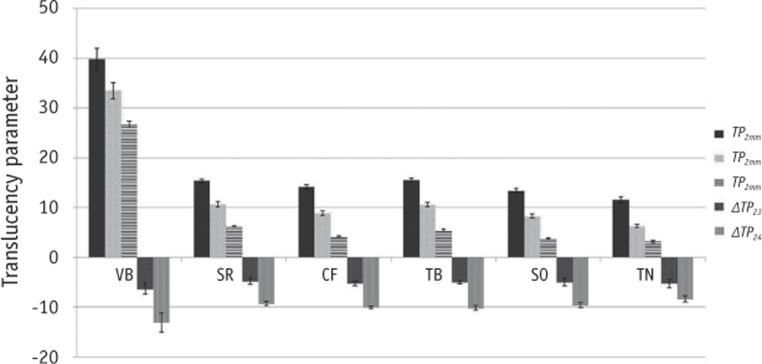

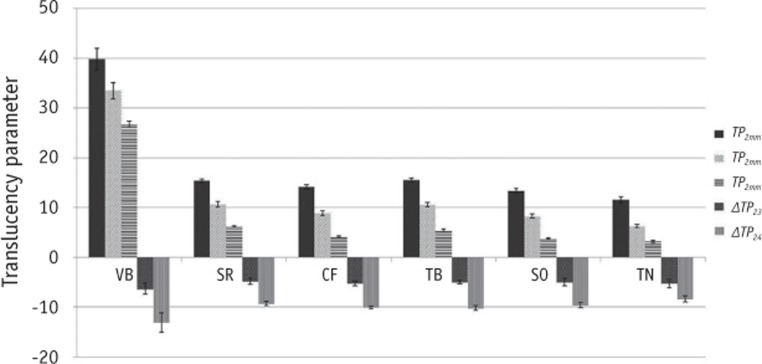

Translucency parameter (TP) and ΔTP of each group.

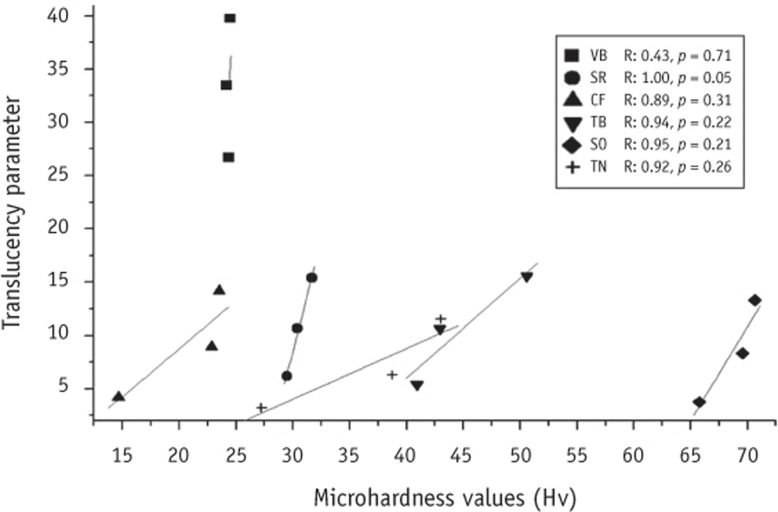

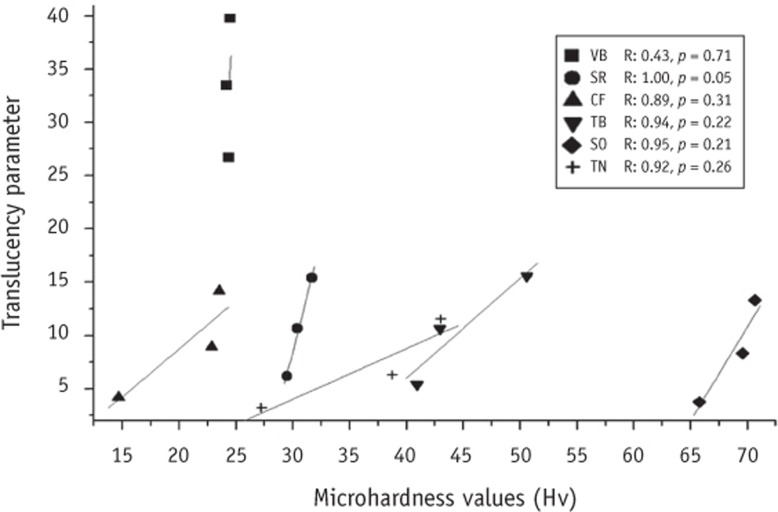

Correlation between microhardness and TP according to resin thickness.

Resin composites used in this study

Microhardness (Hv) for the different thickness

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

Different superscript letters indicate a statistically significant difference among groups (p < 0.05).

Statistical results: model, p < 0.001; resin composites, p < 0.001; thickness, p < 0.001; interaction effect of resin composites × thickness, p < 0.001.

Generalized linear model for comparison of resin composites and thickness, as well as their interaction

CIE L*a*b* color coordinate values of resin composites with different thickness

Color difference (ΔE) values for the different thickness

Tables & Figures

REFERENCES

Citations

- Experimental study of polishing systems on surface roughness and color stability of novel bulk-fill composite resins

Seda Nur Karakaş, Sevde Gül Batmaz, Volkan Çiftçi, Cihan Küden

BMC Oral Health.2025;[Epub] CrossRef - Color Change in Commercial Resin Composites with Different Photoinitiators

Feng Gao, David W. Berzins

Bioengineering.2025; 12(10): 1047. CrossRef - Fracture resistance of milled and 3D printed ultra-thin occlusal veneers made of CAD/CAM resin-based ceramics cemented by variable luting approaches

Ali A. Elkaffas, Abdullah Alshehri, Abdullah Ali Alqahtani, Abdulellah F. Almudahi, Khalid K. Alanazi, Feras Abdulqader Alhalabi, Mohammed Ali Abuelqomsan, Ali R. Alqahtani

BMC Oral Health.2025;[Epub] CrossRef - COLOUR STABILITY OF COMPOSITE RESINS IN THE PRESENCE OF HERBAL TEAS: A SPECTROPHOTOMETRIC STUDY

GOWRISH S., VANDANA SADANANDA, MURTAZA HATIM ZAKIYUDDIN

International Journal of Applied Pharmaceutics.2025; : 308. CrossRef - Comparison of Color Stability Between Single-Layer Bulk-Fill Composites and Bilayer Conventional and Bulk-Fill Composites

Hyunduk Kim, Hyuntae Kim, Ji-Soo Song, Mohammad AlQarni, Mohammad Alkeshan, Teo Jeon Shin, Young-Jae Kim, Jung-Wook Kim, Ki-Taeg Jang, Hong-Keun Hyun

THE JOURNAL OF THE KOREAN ACADEMY OF PEDTATRIC DENTISTRY.2025; 52(3): 266. CrossRef - Surface roughness of flowable bulk fill composite resin by different polishing protocols

Youn-Su Choi, Youngmin Kwon, Jin-Woo Kim, Se-Hee Park, Kyung-Mo Cho

Journal of Dental Rehabilitation and Applied Science.2025; 41(3): 188. CrossRef - The effect of polishing pastes on the surface roughness, microhardness, gloss, and color change of resin composites

Murat Büyükpolat, Numan Aydın, Bilge Eryılmaz, Serpil Karaoğlanoğlu, Bilge Ersöz

BMC Oral Health.2025;[Epub] CrossRef - Predictors of procedural errors in class II resin composite restorations using bitewing radiographs

Abdulrahman A. Balhaddad, Nawaf AlGhamdi, Mohammed Alqahtani, Osama A. Alsulaiman, Ali Alshammari, Malik J. Farraj, Ahmed A. Alsulaiman

The Saudi Dental Journal.2024; 36(4): 638. CrossRef - Evaluation of Surface Roughness and Microhardness of Bulk-fill and Nanohybrid Composite after Exposure to Different Beverages at Various Time Intervals – An In vitro Study

Sachin Bengal, Gautam P. Badole, Pratima R. Shenoi, Rajesh Kubde, Shriya Shahu

Annals of African Medicine.2024; 23(3): 466. CrossRef - Influence of Light‐Curing Time and Increment Thickness on the Properties of Bulk Fill Composite Resins With Distinct Application Systems

Carlos Rocha Gomes Torres, Taiana Paola Prado, Daniele Mara da Silva Ávila, Cesar Rogério Pucci, Alessandra Bühler Borges, Heng Bo Jiang

International Journal of Dentistry.2024;[Epub] CrossRef - Preheating effect on microhardness and depth of cure of three bulk-fill composite resins: An in vitro study

Aashna Sunil Sahetia, Divya Rupesh Jain, Padmaja Panditrao Sirsat, Meenal N. Gulve, Swapnil J. Kolhe, Surbhi P. Patel

Endodontology.2024;[Epub] CrossRef - Clinical Longevity of Sonicated and Unsonicated Composite Resin Restorations in Posterior Permanent Teeth: A Systematic Review and Meta-Analysis

Lorrane Salvador de Mello, Fabiola Fontes Galdino, Jayzon Stephan Brooks, Tatiana Kelly da Silva Fidalgo, Kátia Rodrigues Reis

Pesquisa Brasileira em Odontopediatria e Clínica Integrada.2024;[Epub] CrossRef - Translucency of bulk‐fill composite materials: A systematic review

Gaetano Paolone, Sofia Baldani, Niccolò De Masi, Mauro Mandurino, Giacomo Collivasone, Nicola Scotti, Enrico Gherlone, Giuseppe Cantatore

Journal of Esthetic and Restorative Dentistry.2024; 36(7): 995. CrossRef - Assessment of Microhardness of Bulk-Fill Class II Resin Composite Restorations Performed by Preclinical Students: An In Vitro Study

Ali Abdel-Halim Abdel-Azim Hassan, Abdulelah Sameer Sindi, Abeer Mohamed Atout, Mohamed SM Morsy, Khurshid A. Mattoo, Vishnu Teja Obulareddy, Ankita Mathur, Vini Mehta

European Journal of General Dentistry.2024; 13(02): 158. CrossRef - Effect of Indenter Load on Vickers Microhardness and Indentation Depth of One Resin Composite

Richard B. Price, Braden Sullivan

Materials.2024; 17(24): 6156. CrossRef - The Effect of Layer Thickness and Light Intensity on the Degree of Conversion, Microhardness and Cytotoxicity of Bulk Fill Composite Resins

Sevde Gül BATMAZ, Ayşe DÜNDAR, Çağatay BARUTÇUGİL

Clinical and Experimental Health Sciences.2023; 13(4): 795. CrossRef - Comparative Evaluation of the Color Stability and Clinical performance of bulk-filled composites: A Split-mouth Randomized Controlled Trial

Karuna YM, Srikant N, Kundabala M, Anupama Nayak P, Ashwin Rao, Maimoona TM

Research Journal of Pharmacy and Technology.2023; : 5091. CrossRef - Effect of Using Manufacturer-recommended Exposure Times to Photo-activate Bulk-fill and Conventional Resin-based Composites

LM Barcelos, SSL Braga, RAS Pereira, RB Price, CJ Soares

Operative Dentistry.2023; 48(3): 304. CrossRef - Effect of Different Polymerization Times on Color Change, Translucency Parameter, and Surface Hardness of Bulk-Fill Resin Composites

HY Gonder, M Fidan

Nigerian Journal of Clinical Practice.2022; 25(10): 1751. CrossRef - The effect of contemporary finishing and polishing systems on the surface roughness of bulk fill resin composite and nanocomposites

Seda Gömleksiz, Oğuzhan Gömleksiz

Journal of Esthetic and Restorative Dentistry.2022; 34(6): 915. CrossRef - Evaluation of the microleakage in class II cavities restored with composite resin by using different placement techniques and light cure units– An in vitro study

Swathi Miskin, Chandrasekhar Manduru, Nagalakshmi Reddy Sampathi, Upendranatha Reddy Nagireddy, Sujayeendranatha Reddy E, Sushma Chandra

International Dental Journal of Student's Research.2022; 10(2): 53. CrossRef - Comparison of mechanical and optical properties of a newly marketed universal composite resin with contemporary universal composite resins: An in vitro study

Sevil Gurgan, Uzay Koc Vural, Ivana Miletic

Microscopy Research and Technique.2022; 85(3): 1171. CrossRef - Effect of Additional Light Curing on Colour Stability of Composite Resins

Kubra Alan Unsal, Emel Karaman

International Dental Journal.2022; 72(3): 346. CrossRef - Evaluation of Glass-Ionomer versus Bulk-Fill Resin Composite: A Two-Year Randomized Clinical Study

İlhan Uzel, Arzu Aykut-Yetkiner, Nazan Ersin, Fahinur Ertuğrul, Elif Atila, Mutlu Özcan

Materials.2022; 15(20): 7271. CrossRef - Awareness and Utilization of Bulk-Fill Composites among Dental Practitioners in Saudi Arabia

Hani M. Nassar, Ensanya A. Abou Neel

The Open Dentistry Journal.2021; 15(1): 160. CrossRef - Dental Bulk-Fill Resin Composites Polymerization Efficiency: A Systematic Review and Meta-Analysis

Reem Ajaj, Nada Farsi, Lama Alzain, Nour Nuwaylati, Raneem Ghurab, Hani Nassar

Journal of Composites Science.2021; 5(6): 149. CrossRef - Handling and Mechanical Properties of Low-viscosity Bulk-fill Resin Composites

E Hirokane, T Takamizawa, T Tamura, S Shibasaki, A Tsujimoto, WW Barkmeier, MA Latta, M Miyazaki

Operative Dentistry.2021; 46(5): E185. CrossRef - Utilizing Light Cure Units: A Concise Narrative Review

Fatin A. Hasanain, Hani M. Nassar

Polymers.2021; 13(10): 1596. CrossRef - The Effect of Different Dietary and Therapeutic Solutions on the Color Stability of Resin-Matrix Composites Used in Dentistry: An In Vitro Study

Lígia Lopes-Rocha, José Manuel Mendes, Joana Garcez, Ana Góis Sá, Teresa Pinho, Júlio C. M. Souza, Orlanda Torres

Materials.2021; 14(21): 6267. CrossRef - Fracture resistance of endodontically treated premolars restored with bulk-fill composite resins

Fereshteh Shafiei, Paria Dehghanian, Nasibeh Ghaderi, Maryam Doozandeh

Dental Research Journal.2021; 18(1): 60. CrossRef - Mechanical properties of low and regular viscosity bulk fill composites in a 3D dentin cavity model

Rodolfo Xavier Sousa-Lima, Ana Margarida dos Santos Melo, Lílian Karine Cardoso Guimarães, Rodrigo Othávio de Assunção e Souza, Marília Regalado Galvão Rabelo Caldas, Isauremi Vieira de Assunção, Boniek Castillo Dutra Borges

Journal of Adhesion Science and Technology.2021; 35(3): 325. CrossRef - Comparative analysis of the strength characteristics of light polymerization polymers for dental restoration using the acoustic emission method. Fractographic studies of the surface and fractures of the samples: part two

V. Kukhta, V. Makeev, O. Kyrmanov, V. Skalsky, O. Stankevich

SUCHASNA STOMATOLOHIYA.2021; 109(5): 23. CrossRef - Impact of light-cure protocols on the porosity and shrinkage of commercial bulk fill dental resin composites with different flowability

Daina Dayana Arenas Buelvas, João Felipe Besegato, Bruno Luiz Santana Vicentin, Eduardo Inocente Jussiani, Márcio Grama Hoeppner, Avacir Casanova Andrello, Eduardo Di Mauro

Journal of Polymer Research.2020;[Epub] CrossRef - Effect of time on the post-irradiation curing of six resin-based composites

Christina Kaiser, Richard Bengt Price

Dental Materials.2020; 36(8): 1019. CrossRef The Effects of Irradiance on Translucency and Surface Gloss of Different Bulk-Fill Composite Resins: An in vitro Study

Abrar N Bin Nooh, Hend Al Nahedh, Mohammad AlRefeai, Fahad AlKhudhairy

Clinical, Cosmetic and Investigational Dentistry.2020; Volume 12: 571. CrossRef- Color Stability and Micro-Hardness of Bulk-Fill Composite Materials after Exposure to Common Beverages

Nora Bahbishi, Waad Mzain, Bayan Badeeb, Hani M. Nassar

Materials.2020; 13(3): 787. CrossRef - Polymerization Stress and Gap Formation of Self-adhesive, Bulk-fill and Flowable Composite Resins

EL Nakano, ASC de Souza, LCC Boaro, LH Catalani, RR Braga, F Gonçalves

Operative Dentistry.2020; 45(6): E308. CrossRef - Varying the Polishing Protocol Influences the Color Stability and Surface Roughness of Bulk-Fill Resin-Based Composites

Filipa Freitas, Teresa Pinheiro de Melo, António HS Delgado, Paulo Monteiro, João Rua, Luís Proença, Jorge Caldeira, Ana Mano Azul, José João Mendes

Journal of Functional Biomaterials.2020; 12(1): 1. CrossRef - Characterization and Comparative Analysis of Voids in Class II Composite Resin Restorations by Optical Coherence Tomography

CA Pardo Díaz, CAK Shimokawa, CS Sampaio, AZ Freitas, ML Turbino

Operative Dentistry.2020; 45(1): 71. CrossRef - Clinical performance and chemical-physical properties of bulk fill composites resin —a systematic review and meta-analysis

Leticia Cristina Cidreira Boaro, Diana Pereira Lopes, Andréia Santos Caetano de Souza, Ellea Lie Nakano, Mirko Dennys Ayala Perez, Carmem Silvia Pfeifer, Flávia Gonçalves

Dental Materials.2019; 35(10): e249. CrossRef - Evaluation of the Polymerization Depth of Bulk Fill Resin Composites Polymerized by Different Procedures: An In-Vitro Study

Esra ÖZYURT, Aysegul KURT, Handan YILDIRIM

Clinical and Experimental Health Sciences.2019; 9(4): 304. CrossRef - Internal adaptation of composite restorations with or without an intermediate layer: Effect of polymerization shrinkage parameters of the layer material

Seung-Hoon Han, Alireza Sadr, Yasushi Shimada, Junji Tagami, Sung-Ho Park

Journal of Dentistry.2019; 80: 41. CrossRef - Color Stability of Bulk-Fill Resin Composites after Immersion in Different Media

Sungkyoon Kang, Jihyun Song

THE JOURNAL OF THE KOREAN ACADEMY OF PEDTATRIC DENTISTRY.2019; 46(4): 353. CrossRef - Degree of Conversion and Polymerization Shrinkage of Low Shrinkage Bulk-Fill Resin Composites

Haidy N. Salem, Sherif M. Hefnawy, Shaymaa M. Nagi

Contemporary Clinical Dentistry.2019; 10(3): 465. CrossRef - Bulk-Fill Composites: Effectiveness of Cure With Poly- and Monowave Curing Lights and Modes

JK Gan, AU Yap, JW Cheong, N Arista, CBK Tan

Operative Dentistry.2018; 43(2): 136. CrossRef - Depth of cure of bulk fill resin composites: A systematic review

Renally Bezerra Wanderley Lima, Cristhian Camilo Madrid Troconis, Marina Barrêto Pereira Moreno, Fabián Murillo‐Gómez, Mario Fernando De Goes

Journal of Esthetic and Restorative Dentistry.2018; 30(6): 492. CrossRef - Influence of Bulk Thickness, Curing Time, and Curing Unit Type on the Microhardness of Different-Viscosity Bulk-Fill Composites

M. Saipullaev, U. Erdemir, E. Yildiz

Mechanics of Composite Materials.2018; 54(5): 675. CrossRef - Color of bulk‐fill composite resin restorative materials

Çağatay Barutcigil, Kubilay Barutcigil, Mehmet Mustafa Özarslan, Ayşe Dündar, Burak Yilmaz

Journal of Esthetic and Restorative Dentistry.2018;[Epub] CrossRef - Incremental and Bulk-fill Techniques With Bulk-fill Resin Composite in Different Cavity Configurations

S-H Han, S-H Park

Operative Dentistry.2018; 43(6): 631. CrossRef - Surface changes of various bulk‐fill resin‐based composites after exposure to different food‐simulating liquid and beverages

Saijai Tanthanuch, Boonlert Kukiattrakoon, Kasidit Eiam‐O‐Pas, Kan Pokawattana, Nicha Pamanee, Wichachon Thongkamkaew, Asok Kochatung

Journal of Esthetic and Restorative Dentistry.2018; 30(2): 126. CrossRef - Impact of 35% Hydrogen Peroxide on Color and Translucency Changes in Enamel and Dentin

Rebeca Pereira de Menezes, Paula Damasceno Silva, Pollyana Caldeira Leal, André Luis Faria-e-Silva

Brazilian Dental Journal.2018; 29(1): 88. CrossRef - A comparative study of bulk-fill composites: degree of conversion, post-gel shrinkage and cytotoxicity

Flávia Gonçalves, Luiza Mello de Paiva Campos, Ezequias Costa Rodrigues-Júnior, Fabrícia Viana Costa, Pamela Adeline Marques, Carlos Eduardo Francci, Roberto Ruggiero Braga, Letícia Cristina Cidreira Boaro

Brazilian Oral Research.2018;[Epub] CrossRef - Comparison of cytotoxicity test models for evaluating resin-based composites

SM Lim, AUJ Yap, CSL Loo, J Ng, CY Goh, CHL Hong, WS Toh

Human & Experimental Toxicology.2017; 36(4): 339. CrossRef - Comparison of Internal Adaptation in Class II Bulk-fill Composite Restorations Using Micro-CT

SH Han, SH Park

Operative Dentistry.2017; 42(2): 203. CrossRef - Color stability of bulk-fill and incremental-fill resin-based composites polished with aluminum-oxide impregnated disks

Uzay Koc-Vural, Ismail Baltacioglu, Pinar Altinci

Restorative Dentistry & Endodontics.2017; 42(2): 118. CrossRef - Evaluation of bulk-fill resin composite on the shear bond strength of metal brackets

Mi-Gyoung Park

Korean Journal of Dental Materials.2017; 44(2): 95. CrossRef - Effect of water storage on flexural strength of silorane and methacrylate-based composite resins

Narges Panahandeh, Hassan Torabzadeh, Hani Naderi, Seyedeh Mahsa Sheikh-Al-Eslamian

Restorative Dentistry & Endodontics.2017; 42(4): 309. CrossRef - Shear bond strength of different dentin substitute restorative materials to dentin of primary teeth

Faika ABDELMEGID, Fouad SALAMA, Nawaf ALBOGAMI, Muhannad ALBABTAIN, Abdulkareem ALQAHTANI

Dental Materials Journal.2016; 35(5): 782. CrossRef - Internal adaptation of resin composites at two configurations: Influence of polymerization shrinkage and stress

Seung-Hoon Han, Alireza Sadr, Junji Tagami, Sung-Ho Park

Dental Materials.2016; 32(9): 1085. CrossRef - Effect of a broad-spectrum LED curing light on the Knoop microhardness of four posterior resin based composites at 2, 4 and 6-mm depths

Maan M. ALShaafi, Thomas Haenel, Braden Sullivan, Daniel Labrie, Mohammed Q. Alqahtani, Richard B. Price

Journal of Dentistry.2016; 45: 14. CrossRef - Influence of increment thickness on light transmission, degree of conversion and micro hardness of bulk fill composites

Sufyan Garoushi, Pekka Vallittu, Akikazu Shinya, Lippo Lassila

Odontology.2016; 104(3): 291. CrossRef - Criteria for clinical translucency evaluation of direct esthetic restorative materials

Yong-Keun Lee

Restorative Dentistry & Endodontics.2016; 41(3): 159. CrossRef - The effect of different drinks on the color stability of different restorative materials after one month

Neslihan Tekçe, Safa Tuncer, Mustafa Demirci, Merve Efe Serim, Canan Baydemir

Restorative Dentistry & Endodontics.2015; 40(4): 255. CrossRef

Figure 1

Figure 2

Figure 3

Resin composites used in this study

| Material / shade | Manufacturer | Resin matrix | Filler | Filler content (wt%) | Recommendation | |

|---|---|---|---|---|---|---|

| Flowable composite | Venus Bulk Fill (VB) / Universal shade | Heraeus Kulzer, Hanau, Germany | UDMA, EBADMA | Ba-Al-F-Si glass, SiO2 | 65 | 4 mm bulk-filling with a capping layer |

| SDR (SR) / Universal shade | Dentsply Caulk, Milford, DE, USA | Modified UDMA, TEGDMA, EBADMA | Ba-Al-F-B-Si glass, St-Al-F-Si glass | 68 | 4 mm bulk-filling with a capping layer | |

| Charisma flow (CF) / A2 shade | Heraeus Kulzer, Hanau, Germany | EBADMA, TEGDMA | Ba-Al-F silicate glass, SiO2 | 62 | 2 mm incremental filling | |

| Non-flowable composite | Tetric N-Ceram Bulk Fill (TB) / IVA shade | Ivoclar vivadent, Schaan, Liechtenstein | Bis-GMA, UDMA | Ba-Al-Si glass, prepolymerized filler (monomer, glass filler, and ytterbium fluoride), pherical mixed oxide | 75 - 77 | 4 mm bulk-filling without capping |

| SonicFill (SO) / A2 shade | Kerr, Orange, CA, USA | Bis-GMA, TEGDMA, EBADMA | SiO2, glass, oxide | 83.5 | 5 mm bulk-filling without capping | |

| Tetric N-Ceram (TN) / A2 shade | Ivoclar vivadent, Schaan, Liechtenstein | Bis-GMA, UDMA | Ba glass, Ytterbium trifluoride, mixed oxide | 80 - 81 | 2 mm incremental filling | |

UDMA, urethane dimethacrylate; EBADMA, ethoxylated bisphenol A dimethacrylate; TEGDMA, triethyleneglycol dimethacrylate; Bis-GMA, bisphenol A diglycidyl ether dimethacrylate.

Microhardness (Hv) for the different thickness

| Group | 0 mm | 2 mm | 3 mm | 4 mm | |

|---|---|---|---|---|---|

| Flowable composite | VB | 25.87 ± 0.17d | 24.52 ± 0.22c | 24.19 ± 0.30c | 24.37 ± 0.39c |

| SR | 33.77 ± 0.51h | 31.68 ± 0.67g | 30.39 ± 0.26f | 29.48 ± 0.72f | |

| CF | 24.26 ± 1.30c | 23.52 ± 0.45bc | 22.84 ± 0.33b | 14.66 ± 0.44a | |

| Non-flowable composite | TB | 51.98 ± 0.71m | 50.58 ± 0.53l | 42.92 ± 0.39k | 40.91 ± 0.76j |

| SO | 77.56 ± 0.31p | 70.65 ± 1.07o | 69.53 ± 1.22o | 65.75 ± 0.86n | |

| TN | 51.96 ± 0.88m | 42.99 ± 0.58k | 38.72 ± 0.96i | 27.23 ± 0.86e | |

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

Different superscript letters indicate a statistically significant difference among groups (p < 0.05).

Statistical results: model, p < 0.001; resin composites, p < 0.001; thickness, p < 0.001; interaction effect of resin composites × thickness, p < 0.001.

Generalized linear model for comparison of resin composites and thickness, as well as their interaction

| Variable | Type III sum of squares | df | Mean square | F | p |

|---|---|---|---|---|---|

| Intercept | 31339.181 | 1 | 31339.181 | 55613.467 | 0 |

| Resin composite | 14831.240 | 5 | 2966.248 | 5263.805 | 0 |

| Thickness | 3036.727 | 2 | 1518.364 | 2694.437 | 0 |

| Resin composite*thickness | 71.349 | 10 | 7.135 | 12.661 | 0 |

Adjusted R2 = 0.994.

CIE L*a*b* color coordinate values of resin composites with different thickness

| Group | 2 mm | 3 mm | 4 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | L* | a* | b* | |

| VB | 43.57 ± 1.65 | -5.51 ± 0.24 | -4.45 ± 0.88 | 45.23 ± 1.62 | -5.66 ± 0.37 | -1.70 ± 0.85 | 44.16 ± 0.85 | -5.85 ± 0.06 | 1.39 ± 0.35 |

| SR | 63.34 ± 1.19 | -4.42 ± 0.23 | -1.95 ± 0.30 | 63.23 ± 0.70 | -4.51 ± 0.05 | -1.49 ± 0.35 | 64.55 ± 0.29 | -5.19 ± 0.02 | -1.58 ± 0.30 |

| CF | 59.71 ± 0.80 | 0.01 ± 0.08 | 9.10 ± 0.34 | 59.35 ± 0.51 | 0.36 ± 0.20 | 9.40 ± 0.58 | 58.31 ± 0.48 | 0.43 ± 0.17 | 9.19 ± 0.54 |

| TB | 60.48 ± 0.36 | -3.16 ± 0.03 | 8.67 ± 0.48 | 61.31 ± 0.65 | -2.96 ± 0.05 | 9.18 ± 0.50 | 61.26 ± 0.55 | -2.90 ± 0.12 | 9.23 ± 0.44 |

| SO | 63.04 ± 0.71 | 1.23 ± 0.15 | 4.24 ± 0.25 | 63.38 ± 0.49 | 1.56 ± 0.32 | 4.82 ± 0.71 | 63.48 ± 0.34 | 1.78 ± 0.07 | 4.91 ± 0.22 |

| TN | 63.26 ± 1.06 | -0.01 ± 0.13 | 11.65 ± 0.68 | 63.99 ± 1.08 | 0.16 ± 0.08 | 12.36 ± 0.86 | 61.94 ± 0.46 | 1.11 ± 0.16 | 14.30 ± 0.23 |

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

Color difference (ΔE) values for the different thickness

| Group | ΔE23 | ΔE24 | p value* | ||

|---|---|---|---|---|---|

| Flowable composite | Bulk-fill | VB | 3.33 ± 1.26 | 6.03 ± 0.83 | p < 0.05 |

| SR | 1.62 ± 0.20 | 2.08 ± 0.58 | p < 0.05 | ||

| Regular | CF | 1.00 ± 0.40 | 1.68 ± 0.47 | p < 0.05 | |

| Non-flowable composite | Bulk-fill | TB | 1.54 ± 0.82 | 1.21 ± 0.45 | p > 0.05 |

| SO | 1.11 ± 0.55 | 1.10 ± 0.37 | p > 0.05 | ||

| Regular | TN | 2.07 ± 0.66 | 3.39 ± 0.81 | p < 0.05 |

*Student t-test.

ΔE23 means ΔE between 2 mm and 3 mm specimens, and ΔE24 means ΔE between 2 mm and 4 mm specimens.

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

UDMA, urethane dimethacrylate; EBADMA, ethoxylated bisphenol A dimethacrylate; TEGDMA, triethyleneglycol dimethacrylate; Bis-GMA, bisphenol A diglycidyl ether dimethacrylate.

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram. Different superscript letters indicate a statistically significant difference among groups ( Statistical results: model,

Adjusted R2 = 0.994.

VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

*Student Δ VB, Venus Bulk Fill; SR, SDR; CF, Charisma flow; TB, Tetric N-Ceram Bulk Fill; SO, SonicFill; TN, Tetric N-Ceram.

KACD

KACD

ePub Link

ePub Link Cite

Cite