Articles

- Page Path

- HOME > Restor Dent Endod > Volume 33(4); 2008 > Article

- Original Article Stress distribution of three NiTi rotary files under bending and torsional conditions using 3-dimensional finite element analysis

- Tae-Oh Kim1, Chan-Joo Lee2, Byung-Min Kim2, Jeong-Kil Park1, Bock Hur1, Hyeon-Cheol Kim1

-

2008;33(4):-331.

DOI: https://doi.org/10.5395/JKACD.2008.33.4.323

Published online: July 31, 2008

1Department of Conservative Dentistry, School of Dentistry, Pusan National University, Busan, Korea.

2Division of Precision Manufacturing Systems, Pusan National University, Busan, Korea.

- Corresponding Author: Hyeon-Cheol Kim. Department of Conservative Dentistry, School of Dentistry, Pusan National University, 1-10, Ami-Dong, Seo-Gu, Busan, 602-739, Korea. Tel: 82-51-240-7978, golddent@pusan.ac.kr

• Received: April 7, 2008 • Revised: May 13, 2008 • Accepted: May 15, 2008

Copyright © 2008 The Korean Academy of Conservative Dentistry

- 1,432 Views

- 8 Download

- 1 Crossref

Abstract

-

Flexibility and fracture properties determine the performance of NiTi rotary instruments. The purpose of this study was to evaluate how geometrical differences between three NiTi instruments affect the deformation and stress distributions under bending and torsional conditions using finite element analysis.Three NiTi files (ProFile .06 / #30, F3 of ProTaper and ProTaper Universal) were scanned using a Micro-CT. The obtained structural geometries were meshed with linear, eight-noded hexahedral elements. The mechanical behavior (deformation and von Mises equivalent stress) of the three endodontic instruments were analyzed under four bending and rotational conditions using ABAQUS finite element analysis software. The nonlinear mechanical behavior of the NiTi was taken into account.The U-shaped cross sectional geometry of ProFile showed the highest flexibility of the three file models. The ProTaper, which has a convex triangular cross-section, was the most stiff file model. For the same deflection, the ProTaper required more force to reach the same deflection as the other models, and needed more torque than other models for the same amount of rotation. The highest von Mises stress value was found at the groove area in the cross-section of the ProTaper Universal.Under torsion, all files showed highest stresses at their groove area. The ProFile showed highest von Mises stress value under the same torsional moment while the ProTaper Universal showed the highest value under same rotational angle.

- 1. Walia H, Brantley WA, Gerstein H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J Endod. 1988;14: 346-351.ArticlePubMed

- 2. Glossen CR, Haller RH, Dove SB, del Rio CE. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J Endod. 1995;21: 146-151.ArticlePubMed

- 3. Schäfer E, Schulz-Bongert U, Tulus G. Comparison of hand stainless steel and nickel titanium rotary instrumentation: a clinical study. J Endod. 2004;30: 432-435.ArticlePubMed

- 4. Chen JL, Messer HH. A comparison of stainless steel hand and rotary nickel-titanium instrumentation using a silicone impression technique. Aust Dent J. 2002;47: 12-20.ArticlePubMed

- 5. Garip Y, Gunday M. The use of computed tomography when comparing nickel-titanium and stainless steel files during preparation of simulated curved canals. Int Endod J. 2001;34: 452-457.ArticlePubMedPDF

- 6. Schäfe E. Shaping ability of Hero 642 rotary nickel-titanium instruments and stainless steel hand K-Flexofiles in simulated curved root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2001;92: 215-220.ArticlePubMed

- 7. Hata G, Uemura M, Kato AS, Imura N, Novo NF, Toda T. A comparison of shaping ability using ProFile, GT file, and Flex-R endodontic instruments in simulated canals. J Endod. 2002;28: 316-321.ArticlePubMed

- 8. Ankrum MT, Hartwell GR, Trutt JE. K3 Endo, ProTaper, and ProFile systems: breakage and distortion in severely curved root of molars. J Endod. 2004;30: 234-237.PubMed

- 9. Kim HC, Park JK, Hur B. Relative efficacy of three Ni-Ti file systems used by undergraduates. J Korean Acad Conserv Dent. 2005;30: 38-48.Article

- 10. Walsch H. The hybrid concept of nickel-titanium rotary instrumentation. Dent Clin North Am. 2004;48: 183-202.ArticlePubMed

- 11. Park SH, Cho KM, Kim JW. The Efficiency of the Ni-Ti Rotary files in Curved Simulated Canals Shaped by Novice Operators. J Korean Acad Conserv Dent. 2003;28: 146-155.Article

- 12. Bergmans L, Van Cleynenbreugel J, Beullens M, Wevers M, Van Meerbeek B, Lambrechts P. Progressive versus constant tapered shaft design using NiTi rotary instruments. Int Endod J. 2003;36: 288-295.ArticlePubMedPDF

- 13. Clauder T, Baumann MA. ProTaper NT system. Dent Clin North Am. 2004;48: 87-111.ArticlePubMed

- 14. Calberson FL, Deroose CA, Hommez GM, De Moor RJ. Shaping ability of ProTaper nickel-titanium files in simulated resin root canals. Int Endod J. 2004;37: 613-623.ArticlePubMed

- 15. Yun HH, Kim SK. A comparison of the shaping abilities of 4 nickel-titanium rotary instruments in simulated root canals. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003;95: 228-233.ArticlePubMed

- 16. Schäfe E, Vlassis M. Comparative investigation of two rotary nickel-titanium instruments: ProTaper versus RaCe. Part 1. Shaping ability in simulated curved canals. Int Endod J. 2004;37: 229-238.ArticlePubMed

- 17. Grande NM, Plotino G, Pecci R, Bedini R, Malagnino VA, Somma F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int Endod J. 2006;39: 755-763.ArticlePubMed

- 18. Martín B, Zelada G, Varela P, Bahillo JG, Magán F, Ahn S, Rodríguez C. Factors influencing the fracture of nickel-titanium rotary instruments. Int Endod J. 2003;36: 262-266.ArticlePubMedPDF

- 19. Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod. 2000;26: 161-165.ArticlePubMed

- 20. Berutti E, Chiandussi G, Gaviglio I, Ibba A. Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: ProTaper versus ProFile. J Endod. 2003;29: 15-19.ArticlePubMed

- 21. Camps JJ, Pertot WJ, Levallois B. Relationship between file size and stiffness of nickel titanium instruments. Endod Dent Traumatol. 1995;11: 270-273.ArticlePubMed

- 22. Wang GZ. A finite element analysis of evolution of stress-strain and martensite transformation in front of a notch in shape memory alloy NiTi. Mater Sci Eng A Struct Mater. 2007;460-461: 383-391.Article

- 23. Tripi TR, Bonaccorso A, Condorelli GG. Cyclic fatigue of different nickel-titanium endodontic rotary instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2006;102: e106-e114.ArticlePubMed

- 24. Best S, Watson P, Pilliar R, Kulkarni GGK, Yared G. Torsional fatigue and endurance limit of a size 30.06 ProFile rotary instrument. Int Endod J. 2004;37: 370-373.ArticlePubMed

- 25. Plotino G, Grande NM, Sorci E, Malagnino VA, Somma F. Influence of a brushing working motion on the fatigue life of NiTi rotary instruments. Int Endod J. 2007;40: 45-51.ArticlePubMed

- 26. Hübscher W, Barbakow F, Peters OA. Root canal preparation with FlexMaster: assessment of torque and force in relation to canal anatomy. Int Endod J. 2003;36: 883-890.PubMed

- 27. Peters OA, Peters CI, Schonenberger K, Barbakow F. ProTaper rotary root canal preparation: assessment of torque and force in relation to canal anatomy. Int Endod J. 2003;36: 93-99.PubMed

- 28. Boessler C, Peters OA, Zehnder M. Impact of lubricant parameters on rotary instrument torque and force. J Endod. 2007;33: 280-283.ArticlePubMed

- 29. Shen Y, Bian Z, Cheung GS, Peng B. Analysis of defects in ProTaper hand-operated instruments after clinical use. J Endod. 2007;33: 287-290.ArticlePubMed

- 30. Lopes HP, Moreira EJ, Elias CN, de Almeida RA, Neves MS. Cyclic fatigue of ProTaper instruments. J Endod. 2007;33: 55-57.ArticlePubMed

- 31. Yao JH, Schwartz SA, Beeson TJ. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J Endod. 2006;32: 55-57.ArticlePubMed

- 32. Ullmann CJ, Peters OA. Effect of cyclic fatigue on static fracture loads in ProTaper nickel-titanium rotary instruments. J Endod. 2005;31: 183-186.ArticlePubMed

- 33. Cheung GS, Peng B, Bian Z, Shen Y, Darvell BW. Defects in ProTaper S1 instruments after clinical use: fractographic examination. Int Endod J. 2005;38: 802-809.ArticlePubMed

- 34. Turpin YL, Chagneau F, Vulcain JM. Impact of two theoretical cross-sections on torsional and bending stresses of nickel-titanium root canal instrument models. J Endod. 2000;26: 414-417.ArticlePubMed

- 35. Xu X, Eng M, Zheng Y, Eng D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J Endod. 2006;32: 372-375.ArticlePubMed

- 36. Timoshenko SP, Goodier JN. Theory of Elasticity. 1970;McGraw-Hill.

- 37. Schäfer E, Dzepina A, Danesh G. Bending properties of rotary nickel-titanium instruments. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2003;96: 757-763.ArticlePubMed

- 38. Haikel Y, Serfaty R, Bateman G, Senger B, Allemann C. Dynamic and cyclic fatigue of engine-driven rotary nickel-titanium endodontic instruments. J Endod. 1999;25: 434-440.ArticlePubMed

- 39. Yared GM, Bou Dagher FE, Machtou P. Cyclic fatigue of ProFile rotary instruments after clinical use. Int Endod J. 2000;33: 204-207.ArticlePubMed

- 40. Shen Y, Cheung GS, Bian Z, Peng B. Comparison of defects in ProFile and ProTaper systems after clinical use. J Endod. 2006;32: 61-65.ArticlePubMed

- 41. Mandel E, Adib-Yazdi M, Benhamou LM, Lachkar T, Mesgouez C, Sobel M. Rotary Ni-Ti profile systems for preparing curved canals in resin blocks: influence of operator on instrument breakage. Int Endod J. 1999;32: 436-443.ArticlePubMed

- 42. Yared GM, Bou Dagher FE, Machtou P. Influence of rotational speed, torque and operator's proficiency on ProFile failures. Int Endod J. 2001;34: 47-53.ArticlePubMedPDF

REFERENCES

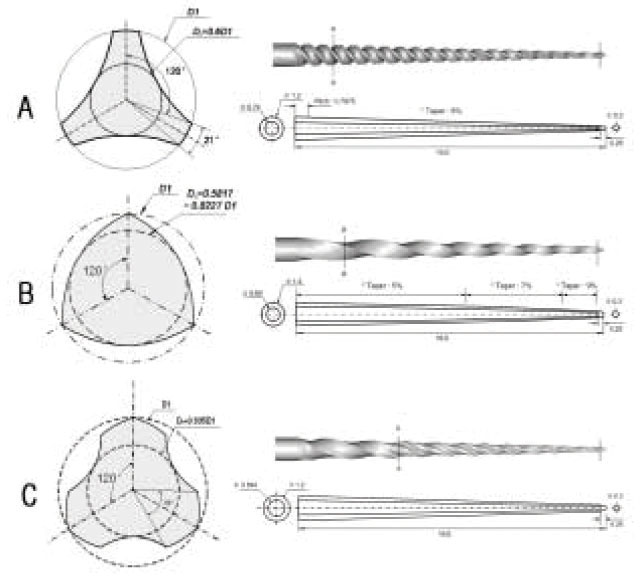

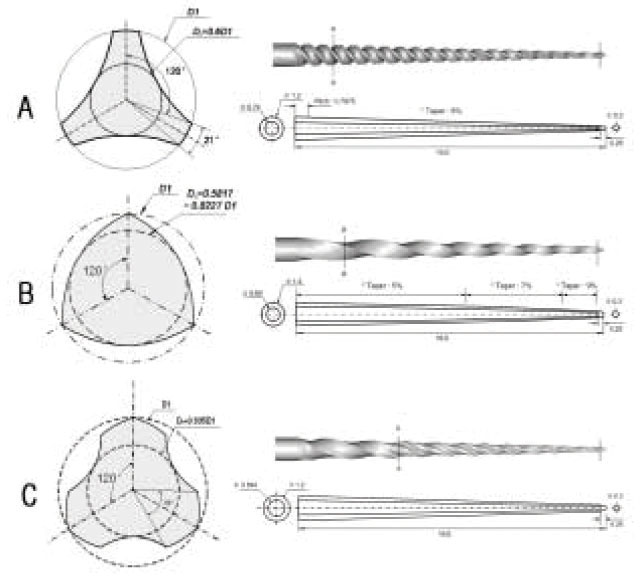

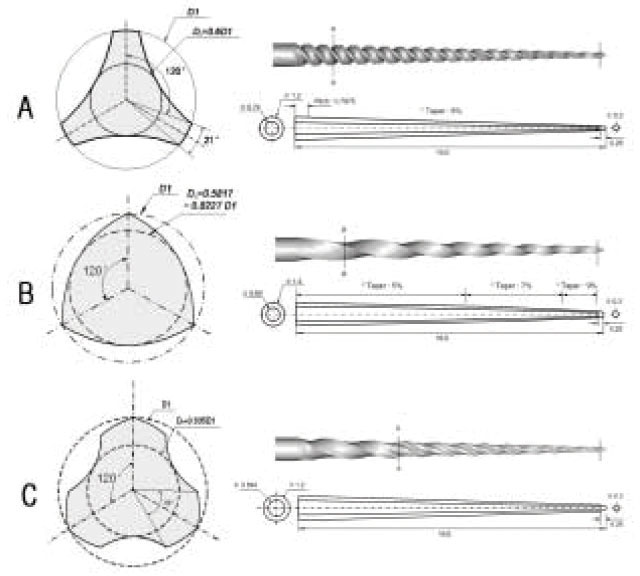

Figure 1

Cross-sectional and longitudinal geometry of three NiTi files. A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

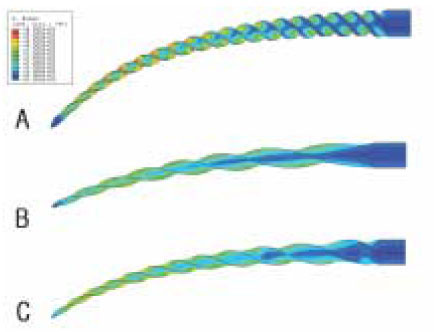

Figure 2

Final FE models of three NiTi files used in this study: A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

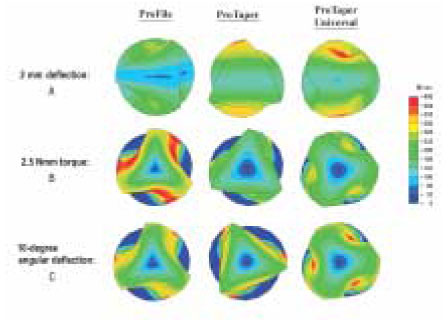

Figure 4

Simulated conditions used in this study: A; The simulated condition of free-end loading of 1 N, B; The simulated condition of same bending distance, C; The torsional condition of 2.5 Nmm with 4 mm fixation, D; The same rotational condition of 10° with 4 mm fixation.

Figure 5

The deflection and stress distribution under the free-end loading. A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

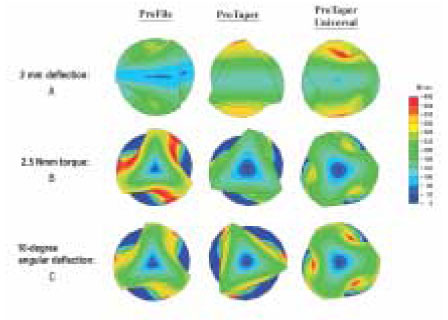

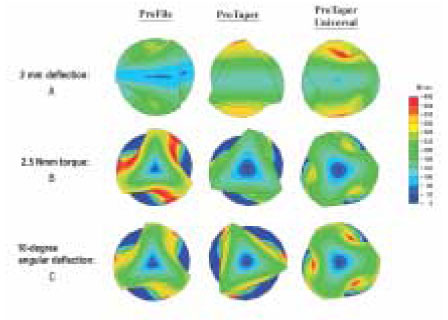

Figure 6

Horizontal row A shows the von Mises stress distribution under the condition of 2 mm deflection. Row B shows the von Mises stress distribution under the condition of 2.5 Nmm torsional moments. Row C shows the von Mises stress distribution under the condition of same rotational angle.

Tables & Figures

REFERENCES

Citations

Citations to this article as recorded by

- Effect of internal stress on cyclic fatigue failure in .06 taper ProFile

Hye-Rim Jung, Jin-Woo Kim, Kyung-Mo Cho, Se-Hee Park

Restorative Dentistry & Endodontics.2012; 37(2): 79. CrossRef

Stress distribution of three NiTi rotary files under bending and torsional conditions using 3-dimensional finite element analysis

Figure 1

Cross-sectional and longitudinal geometry of three NiTi files. A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

Figure 2

Final FE models of three NiTi files used in this study: A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

Figure 3

The stress-strain curve of the NiTi material22).

Figure 4

Simulated conditions used in this study: A; The simulated condition of free-end loading of 1 N, B; The simulated condition of same bending distance, C; The torsional condition of 2.5 Nmm with 4 mm fixation, D; The same rotational condition of 10° with 4 mm fixation.

Figure 5

The deflection and stress distribution under the free-end loading. A; ProFile .06 / #30, B; ProTaper F3, C; ProTaper Universal F3.

Figure 6

Horizontal row A shows the von Mises stress distribution under the condition of 2 mm deflection. Row B shows the von Mises stress distribution under the condition of 2.5 Nmm torsional moments. Row C shows the von Mises stress distribution under the condition of same rotational angle.

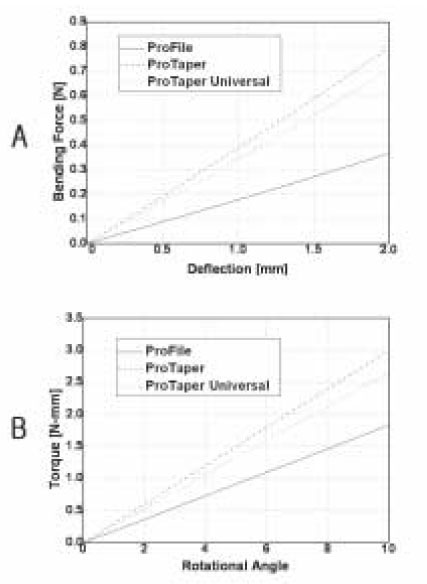

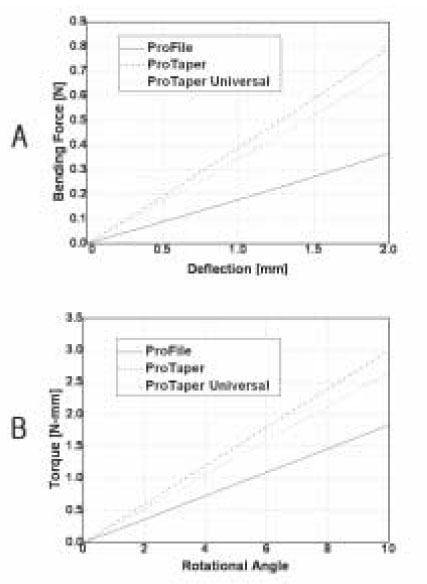

Figure 7

Graph A showing the bending moment needed to deflect. Graph B showing the torque required to rotate the file under the restrained condition.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Stress distribution of three NiTi rotary files under bending and torsional conditions using 3-dimensional finite element analysis

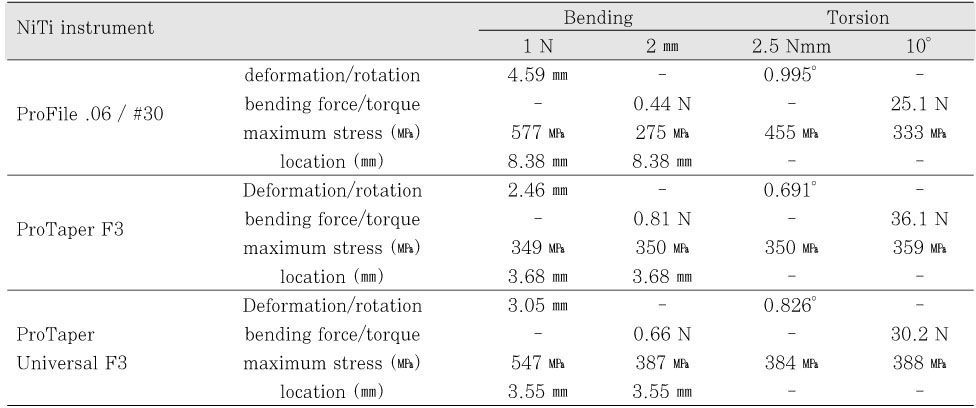

Calculated deformation and maximum von Mises equivalent stress results for three NiTi rotary instruments under four loading conditions. Location of the bending deformation was at the tip of the file, the maximum stress concentration locations were measured from file tip

Table 1

Calculated deformation and maximum von Mises equivalent stress results for three NiTi rotary instruments under four loading conditions. Location of the bending deformation was at the tip of the file, the maximum stress concentration locations were measured from file tip

KACD

KACD

ePub Link

ePub Link Cite

Cite