Search

- Page Path

- HOME > Search

Research Article

- Analysis of temperature change during polymerization according to resin thickness: an in vitro experimental study

- Kkot-Byeol Bae, Eun-Young Noh, Young-Tae Cho, Bin-Na Lee, Hoon-Sang Chang, Yun-Chan Hwang, Won-Mann Oh, In-Nam Hwang

- Restor Dent Endod 2025;50(4):e34. Published online November 12, 2025

- DOI: https://doi.org/10.5395/rde.2025.50.e34

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub - Objectives

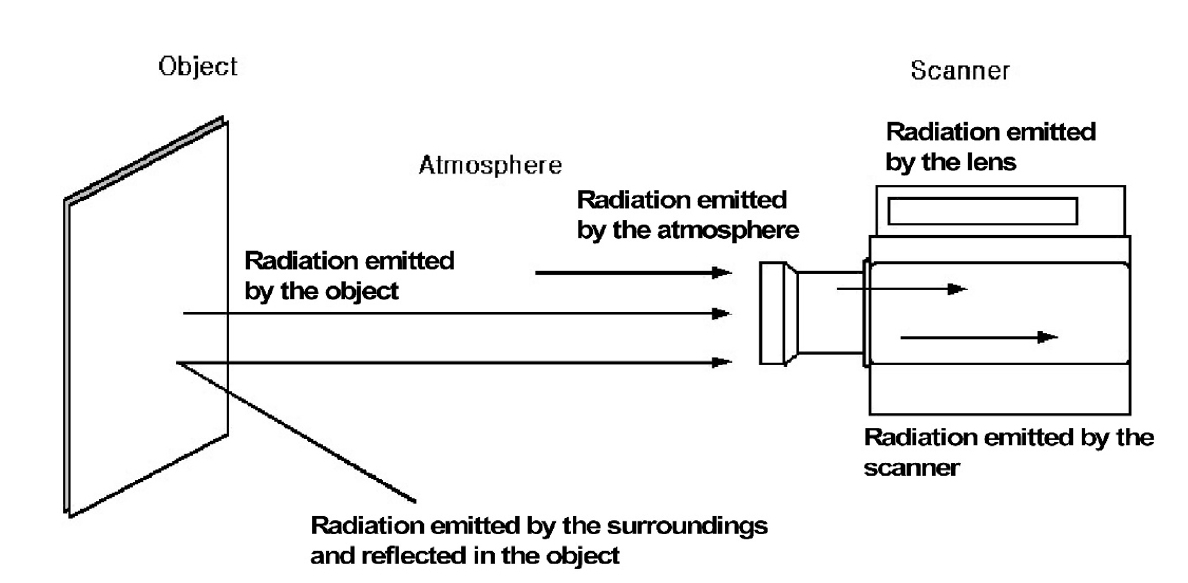

This study aimed to analyze the temperature changes during the light curing of conventional flowable composite resin and bulk-fill composite resin of various thicknesses using an infrared thermographic camera.

Methods

Flowable composite resin (G-aenial Flo, GC Co.) and bulk-fill composite resin (SDR, Dentsply Caulk) were used. Specimens with thicknesses from 0.5 mm to 5.0 mm were prepared. The infrared thermographic camera measured the temperature changes at the maximum temperature rise point during light curing. The data were analyzed for maximum temperature, time to peak temperature, and temperature rise patterns.

Results

For G-aenial Flo, the maximum temperature tended to decrease with increasing thickness, whereas for SDR, the maximum temperature decreased up to 2.0 mm and then remained relatively consistent from 2.0 mm to 5.0 mm. At thicknesses of 1.5 mm or less, both resins showed a rapid temperature increase within the first 5 seconds, followed by a reduced rate of increase up to 80 seconds. At thicknesses of 2.0 mm or greater, the temperature peaked and then gradually decreased. Across all thicknesses, SDR was observed to reach peak temperature more rapidly than G-aenial Flo.

Conclusions

Observable differences in polymerization dynamics were identified between the two resin types, particularly at greater thicknesses. Although no statistical analysis was performed, these descriptive findings suggest that infrared thermographic cameras may be useful for indirectly assessing polymerization dynamics during resin polymerization.

- 780 View

- 57 Download

KACD

KACD

First

First Prev

Prev