Search

- Page Path

- HOME > Search

- Comparison of the cyclic fatigue resistance of One Curve, F6 Skytaper, Protaper Next, and Hyflex CM endodontic files

- Charlotte Gouédard, Laurent Pino, Reza Arbab-Chirani, Shabnam Arbab-Chirani, Valérie Chevalier

- Restor Dent Endod 2022;47(2):e16. Published online March 4, 2022

- DOI: https://doi.org/10.5395/rde.2022.47.e16

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

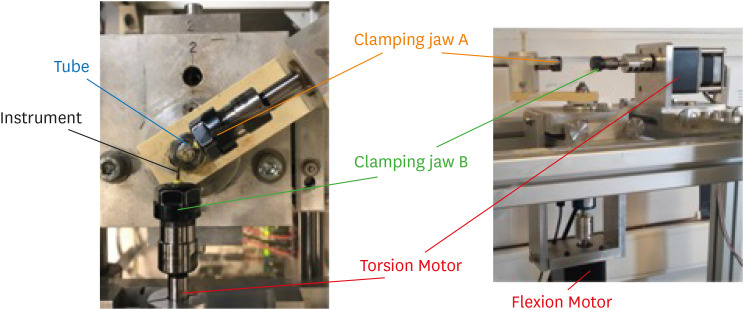

ePub Objectives This study compared the cyclic fatigue resistance of One Curve (C wire) and F6 Skytaper (conventional austenite nickel-titanium [NiTi]), and 2 instruments with thermo-mechanically treated NiTi: Protaper Next X2 (M wire) and Hyflex CM (CM wire).

Materials and Methods Ten new instruments of each group (size: 0.25 mm, 6% taper in the 3 mm tip region) were tested using a rotary bending machine with a 60° curvature angle and a 5 mm curvature radius, at room temperature. The number of cycles until fracture was recorded. The length of the fractured instruments was measured. The fracture surface of each fragment was examined with a scanning electron microscope (SEM). The data were analyzed using one-way analysis of variance and the

post hoc Tukey test. The significance level was set at 0.05.Results At 60°, One Curve, F6 Skytaper and Hyflex CM had significantly longer fatigue lives than Protaper Next X2 (

p < 0.05). No statistically significant differences were found in the cyclic fatigue lives of One Curve, F6 Skytaper, and Hyflex CM (p > 0.05). SEM images of the fracture surfaces of the different instruments showed typical features of fatigue failure.Conclusions Within the conditions of this study, at 60° and with a 5 mm curvature radius, the cyclic fatigue life of One Curve was not significantly different from those of F6 Skytaper and Hyflex CM. The cyclic fatigue lives of these 3 instruments were statistically significantly longer than that of Protaper Next.

-

Citations

Citations to this article as recorded by- Evaluation of cyclic fatigue in three pediatric endodontic rotary file systems in root canals of primary molars: A finite element analysis (FEA)

Monika sri S.S., K.C. Vignesh, K. Vivek, Kavitha Swaminathan, Selvakumar Haridoss

Journal of Oral Biology and Craniofacial Research.2025; 15(2): 310. CrossRef - Stress analysis of different experimental finite element models of rotary endodontic instruments

Manar M. Galal, Amira Galal Ismail, Nada Omar

Bulletin of the National Research Centre.2025;[Epub] CrossRef - Understanding Cyclic Fatigue in Three Nickel–Titanium Pediatric Files: An In Vitro Study for Enhanced Patient Care

Alwaleed Abushanan, Rajashekhara Bhari Sharanesha, Fahd Aljarbou, Hadi Alamri, Mohammed Hamad Almasud, Abdulfatah AlAzmah, Sara Alghamdi, Mubashir Baig Mirza

Medicina.2025; 61(5): 830. CrossRef - Analyzing Surface Morphology Changes Induced by Cyclic Fatigue in Three Different Nickel–Titanium Rotary Files Using Scanning Electron Microscopy Analysis

Chintan Joshi, Mahima P Jain, Sweety M Thumar, Jay H Dave, Applu R Bhatt, Juhi I Dholani

World Journal of Dentistry.2024; 15(7): 579. CrossRef - Nickel ion release and surface analyses on instrument fragments fractured beyond the apex: a laboratory investigation

Sıdıka Mine Toker, Ekim Onur Orhan, Arzu Beklen

BMC Oral Health.2023;[Epub] CrossRef

- Evaluation of cyclic fatigue in three pediatric endodontic rotary file systems in root canals of primary molars: A finite element analysis (FEA)

- 3,232 View

- 43 Download

- 2 Web of Science

- 5 Crossref

- A comparison of dimensional standard of several nickel-titanium rotary files

- Ki-Won Kim, Kyung-Mo Cho, Se-Hee Park, Ki-Yeol Choi, Bekir Karabucak, Jin-Woo Kim

- Restor Dent Endod 2014;39(1):7-11. Published online January 20, 2014

- DOI: https://doi.org/10.5395/rde.2014.39.1.7

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives The aim of this study was to compare the dimensional standard of several nickel-titanium (Ni-Ti) rotary files and verify the size conformity.

Materials and Methods ProFile (Dentsply Maillefer), RaCe (FKG Dentaire), and TF file (SybronEndo) #25 with a 0.04 and 0.06 taper were investigated, with 10 in each group for a total of 60 files. Digital images of Ni-Ti files were captured under light microscope (SZX16, Olympus) at 32×. Taper and diameter at D1 to D16 of each files were calculated digitally with AnalySIS TS Materials (OLYMPUS Soft Imaging Solutions). Differences in taper, the diameter of each level (D1 to D16) at 1 mm interval from (ANSI/ADA) specification No. 101 were statistically analyzed using one-way ANOVA and Scheffe's

post-hoc test at 95% confidence level.Results TF was the only group not conform to the nominal taper in both tapers (

p < 0.05). All groups except 0.06 taper ProFile showed significant difference from the nominal diameter (p < 0.05).Conclusions Actual size of Ni-Ti file, especially TF, was different from the manufacturer's statements.

-

Citations

Citations to this article as recorded by- Ex Vivo Evaluation of the Fit of Matched Gutta Percha Points in Human Root Canals Prepared With the Corresponding Nickel‐Titanium Files

Samuel Deng, Paul V. Abbott

Australian Endodontic Journal.2025; 51(3): 684. CrossRef - Diameter and Taper Variability of Single-file Instrumentation Systems and Their Corresponding Gutta-percha Cones

Franziska Haupt, Miriam Seidel, Marta Rizk, Hans-Georg Sydow, Annette Wiegand, Tina Rödig

Journal of Endodontics.2018; 44(9): 1436. CrossRef

- Ex Vivo Evaluation of the Fit of Matched Gutta Percha Points in Human Root Canals Prepared With the Corresponding Nickel‐Titanium Files

- 1,379 View

- 11 Download

- 2 Crossref

- Effect of surface defects and cross-sectional configuration on the fatigue fracture of NiTi rotary files under cyclic loading

- Yu-Mi Shin, Eui-Sung Kim, Kwang-Man Kim, Kee-Yeon Kum

- J Korean Acad Conserv Dent 2004;29(3):267-272. Published online May 31, 2004

- DOI: https://doi.org/10.5395/JKACD.2004.29.3.267

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub The purpose of this in vitro study was to evaluate the effect of surface defects and cross-sectional configuration of NiTi rotary files on the fatigue life under cyclic loading. Three NiTi rotary files (K3™, ProFile®, and HERO 642®) with #30/.04 taper were evaluated. Each rotary file was divided into 2 subgroups: control (no surface defects) and experimental group (artificial surface defects). A total of six groups of each 10 were tested. The NiTi rotary files were rotated at 300rpm using the apparatus which simulated curved canal (40 degree of curvature) until they fracture. The number of cycles to fracture was calculated and the fractured surfaces were observed with a scanning electron microscope. The data were analyzed statistically. The results showed that experimental groups with surface defects had lower number of cycles to fracture than control group but there was only a statistical significance between control and experimental group in the K3™ (p<0.05). There was no strong correlation between the cross-sectional configuration area and fracture resistance under experimental conditions. Several of fractured files demonstrated characteristic patterns of brittle fracture consistent with the propagation of pre-existing cracks.

This data indicate that surface defects of NiTi rotary files may significantly decrease fatigue life and it may be one possible factor for early fracture of NiTi rotary files in clinical practice.

-

Citations

Citations to this article as recorded by- Torsional behavior and microstructure characterization of additively manufactured NiTi shape memory alloy tubes

Keyvan Safaei, Mohammadreza Nematollahi, Parisa Bayati, Hediyeh Dabbaghi, Othmane Benafan, Mohammad Elahinia

Engineering Structures.2021; 226: 111383. CrossRef - Effect of internal stress on cyclic fatigue failure in K3

Jun-Young Kim, Jin-Woo Kim, Kyung-Mo Cho, Se-Hee Park

Restorative Dentistry & Endodontics.2012; 37(2): 74. CrossRef - An evaluation of rotational stability in endodontic electronic motors

Se-Hee Park, Hyun-Woo Seo, Chan-Ui Hong

Journal of Korean Academy of Conservative Dentistry.2010; 35(4): 246. CrossRef - Effect of cross-sectional area of 6 nickel-titanium rotary instruments on the fatigue fracture under cyclic flexural stress: A fractographic analysis

Soo-Youn Hwang, So-Ram Oh, Yoon Lee, Sang-Min Lim, Kee-Yeon Kum

Journal of Korean Academy of Conservative Dentistry.2009; 34(5): 424. CrossRef - The Effect of Surface Defects on the Cyclic Fatigue Fracture of HEROShaper Ni-Ti rotary files in a Dynamic Model: A Fractographic Analysis

Jung-Kyu Lee, Eui-Sung Kim, Myoung-Whai Kang, Kee-Yeon Kum

Journal of Korean Academy of Conservative Dentistry.2007; 32(2): 130. CrossRef - Comparative study on morphology of cross-section and cyclic fatigue test with different rotary NiTi files and handling methods

Jae-Gwan Kim, Kee-Yeon Kum, Eui-Seong Kim

Journal of Korean Academy of Conservative Dentistry.2006; 31(2): 96. CrossRef

- Torsional behavior and microstructure characterization of additively manufactured NiTi shape memory alloy tubes

- 1,098 View

- 2 Download

- 6 Crossref

KACD

KACD

First

First Prev

Prev