Search

- Page Path

- HOME > Search

- The influence of nanofillers on the properties of ethanol-solvated and non-solvated dental adhesives

- Leonardo Bairrada Tavares da Cruz, Marcelo Tavares Oliveira, Cintia Helena Coury Saraceni, Adriano Fonseca Lima

- Restor Dent Endod 2019;44(3):e28. Published online July 24, 2019

- DOI: https://doi.org/10.5395/rde.2019.44.e28

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives The aim of this study was to evaluate the influence of different concentrations of nanofillers on the chemical and physical properties of ethanol-solvated and non-solvated dental adhesives.

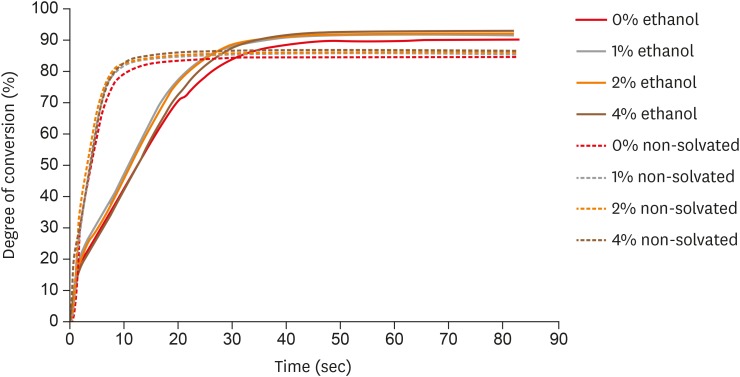

Materials and Methods Eight experimental adhesives were prepared with different nanofiller concentrations (0, 1, 2, and 4 wt%) and 2 solvent concentrations (0% and 10% ethanol). Several properties of the experimental adhesives were evaluated, such as water sorption and solubility (

n = 5, 20 seconds light activation), real-time degree of conversion (DC;n = 3, 20 and 40 seconds light activation), and stability of cohesive strength at 6 months (CS;n = 20, 20 seconds light activation) using the microtensile test. A light-emitting diode (Bluephase 20i, Ivoclar Vivadent) with an average light emittance of 1,200 mW/cm2 was used.Results The presence of solvent reduced the DC after 20 seconds of curing, but increased the final DC, water sorption, and solubility of the adhesives. Storage in water reduced the strength of the adhesives. The addition of 1 wt% and 2 wt% nanofillers increased the polymerization rate of the adhesives.

Conclusions The presence of nanofillers and ethanol improved the final DC, although the DC of the solvated adhesives at 20 seconds was lower than that of the non-solvated adhesives. The presence of ethanol reduced the strength of the adhesives and increased their water sorption and solubility. However, nanofillers did not affect the water sorption and strength of the tested adhesives.

-

Citations

Citations to this article as recorded by- In Vitro Comparison of Gingival Epithesis Materials: Color Stability, Surface Properties, and Microbial Adhesion After Staining

Ellen Pick, Andrea Gubler, Thomas Attin, Patrick R. Schmidlin

Dentistry Journal.2026; 14(3): 142. CrossRef - Effect of boric acid on the color stability and mechanical properties of 3D-printed permanent resins

Dalndushe Abdulai, Rafat Sasany, Raghib Suradi, Mehran Moghbel, Seyed Ali Mosaddad

Scientific Reports.2025;[Epub] CrossRef - Development of a Boron Nitride-Filled Dental Adhesive System

Senthilguru Kulanthaivel, Jeremiah Poppen, Sandra Ribeiro Cunha, Benjamin Furman, Kyumin Whang, Erica C. Teixeira

Polymers.2023; 15(17): 3512. CrossRef - Analyses of Experimental Dental Adhesives Based on Zirconia/Silver Phosphate Nanoparticles

Abdul Khan, Yasmin Alhamdan, Hala Alibrahim, Khalid Almulhim, Muhammad Nawaz, Syed Ahmed, Khalid Aljuaid, Ijlal Ateeq, Sultan Akhtar, Mohammad Ansari, Intisar Siddiqui

Polymers.2023; 15(12): 2614. CrossRef - Mechanical characterization and adhesive properties of a dental adhesive modified with a polymer antibiotic conjugate

Camila Sabatini, Russell J. Aguilar, Ziwen Zhang, Steven Makowka, Abhishek Kumar, Megan M. Jones, Michelle B. Visser, Mark Swihart, Chong Cheng

Journal of the Mechanical Behavior of Biomedical Materials.2022; 129: 105153. CrossRef

- In Vitro Comparison of Gingival Epithesis Materials: Color Stability, Surface Properties, and Microbial Adhesion After Staining

- 1,499 View

- 9 Download

- 5 Crossref

- Effects of radiant exposure and wavelength spectrum of light-curing units on chemical and physical properties of resin cements

- Adriano Fonseca Lima, Stephanie Ellen Ferreira Formaggio, Lígia França Aires Zambelli, Alan Rodrigo Muniz Palialol, Giselle Maria Marchi, Cintia Helena Coury Saraceni, Marcelo Tavares de Oliveira

- Restor Dent Endod 2016;41(4):271-277. Published online September 26, 2016

- DOI: https://doi.org/10.5395/rde.2016.41.4.271

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives In this study, we evaluated the influence of different radiant exposures provided by single-peak and polywave light-curing units (LCUs) on the degree of conversion (DC) and the mechanical properties of resin cements.

Materials and Methods Six experimental groups were established for each cement (RelyX ARC, 3M ESPE; LuxaCore Dual, Ivoclar Vivadent; Variolink, DMG), according to the different radiant exposures (5, 10, and 20 J/cm2) and two LCUs (single-peak and polywave). The specimens were made (7 mm in length × 2 mm in width × 1 mm in height) using silicone molds. After 24 hours of preparation, DC measurement was performed using Fourier transform infrared spectrometry. The same specimens were used for the evaluation of mechanical properties (flexural strength, FS; elastic modulus,

E ) by a three-point bending test. Data were assessed for normality, after which two-way analysis of variance (ANOVA) and post hoc Tukey's test were performed.Results No properties of the Variolink cement were influenced by any of the considered experimental conditions. In the case of the RelyX ARC cement, DC was higher when polywave LCU was used; FS and E were not influenced by the conditions evaluated. The LuxaCore cement showed greater sensitivity to the different protocols.

Conclusions On the basis of these results, both the spectrum of light emitted and the radiant exposure used could affect the properties of resin cements. However, the influence was material-dependent.

-

Citations

Citations to this article as recorded by- Efficiency and limitations of polywave light-curing units in restorative dentistry: a systematic review

Eduardo Fernández Godoy, Alain Chaple Gil, Rodrigo Caviedes Thomas, Cristian Bersezio Miranda, Javier Martín Casielles, Gonzalo Rodríguez Martínez, Pablo Angel Aguirre

Clinical Oral Investigations.2025;[Epub] CrossRef - Light Transmittance and Depth of Cure of a Bulk Fill Composite Based on the Exposure Reciprocity Law

Mateus Garcia Rocha, Jean-François Roulet, Mario Alexandre Coelho Sinhoreti, Américo Bortolazzo Correr, Dayane Oliveira

Brazilian Dental Journal.2021; 32(1): 78. CrossRef

- Efficiency and limitations of polywave light-curing units in restorative dentistry: a systematic review

- 1,834 View

- 4 Download

- 2 Crossref

KACD

KACD

First

First Prev

Prev