-

Cyclic fatigue resistance, torsional resistance, and metallurgical characteristics of M3 Rotary and M3 Pro Gold NiTi files

-

Eugenio Pedullà, Fabio Lo Savio, Giusy Rita Maria La Rosa, Gabriele Miccoli, Elena Bruno, Silvia Rapisarda, Seok Woo Chang, Ernesto Rapisarda, Guido La Rosa, Gianluca Gambarini, Luca Testarelli

-

Restor Dent Endod 2018;43(2):e25. Published online April 23, 2018

-

DOI: https://doi.org/10.5395/rde.2018.43.e25

-

-

Abstract Abstract

PDF PDF PubReader PubReader ePub ePub

- Objectives

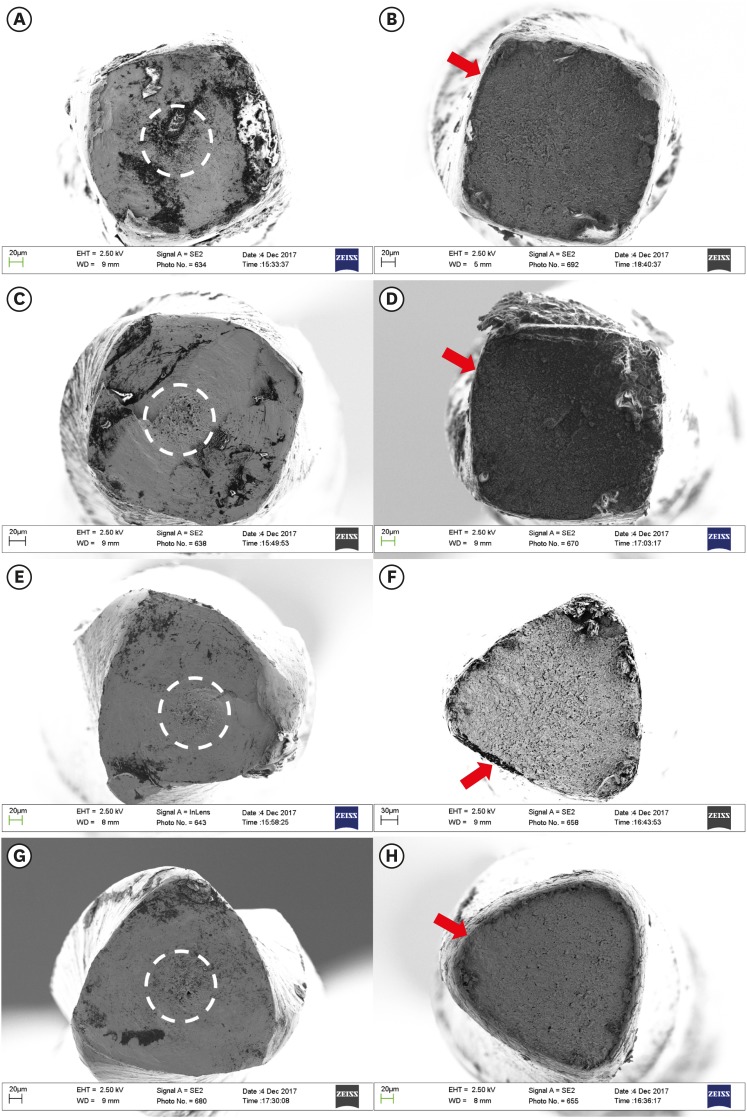

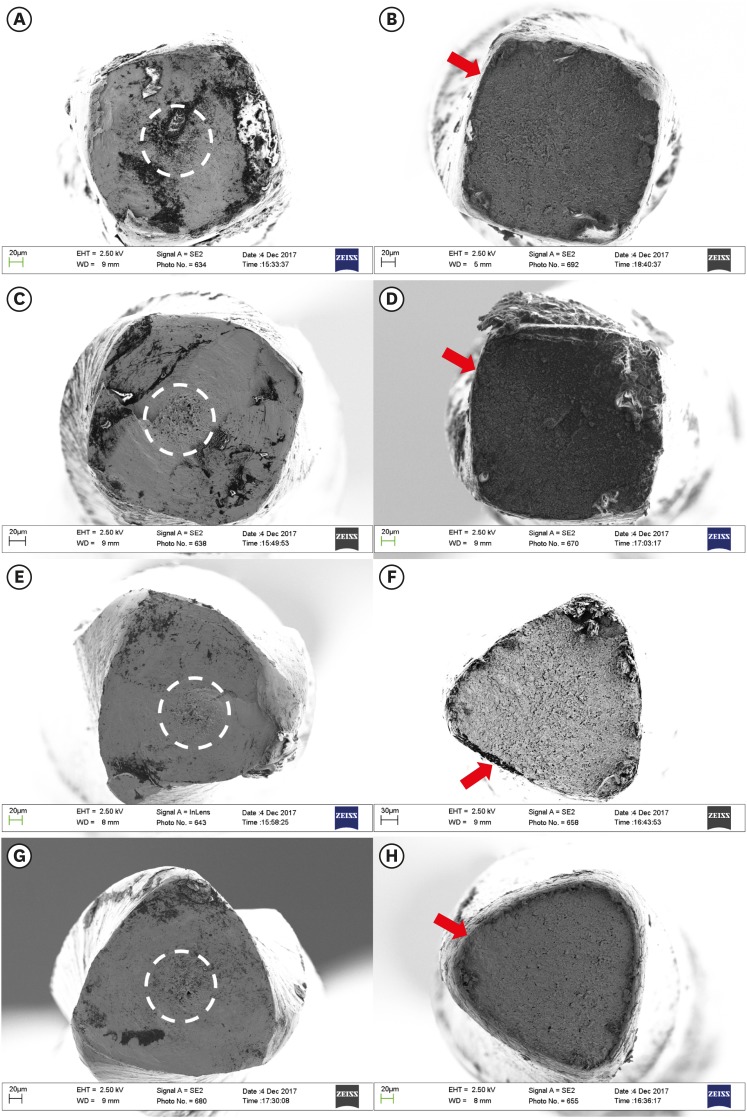

To evaluate the mechanical properties and metallurgical characteristics of the M3 Rotary and M3 Pro Gold files (United Dental). Materials and MethodsOne hundred and sixty new M3 Rotary and M3 Pro Gold files (sizes 20/0.04 and 25/0.04) were used. Torque and angle of rotation at failure (n = 20) were measured according to ISO 3630-1. Cyclic fatigue resistance was tested by measuring the number of cycles to failure in an artificial stainless steel canal (60° angle of curvature and a 5-mm radius). The metallurgical characteristics were investigated by differential scanning calorimetry. Data were analyzed using analysis of variance and the Student-Newman-Keuls test. ResultsComparing the same size of the 2 different instruments, cyclic fatigue resistance was significantly higher in the M3 Pro Gold files than in the M3 Rotary files (p < 0.001). No significant difference was observed between the files in the maximum torque load, while a significantly higher angular rotation to fracture was observed for M3 Pro Gold (p < 0.05). In the DSC analysis, the M3 Pro Gold files showed one prominent peak on the heating curve and 2 prominent peaks on the cooling curve. In contrast, the M3 Rotary files showed 1 small peak on the heating curve and 1 small peak on the cooling curve. ConclusionsThe M3 Pro Gold files showed greater flexibility and angular rotation than the M3 Rotary files, without decrement of their torque resistance. The superior flexibility of M3 Pro Gold files can be attributed to their martensite phase.

-

Citations

Citations to this article as recorded by  - Comparative Evaluation of Dentinal Microcrack Using M3 ProGold, Mtwo Rotary File and Hand File in Root Canal Therapy: An In-Vitro Study

Reyhaneh Shoorgashti, Marzie Jafari, Mohadeseh Alimohammadi, Niloofar Ebrahimi

Middle East Journal of Rehabilitation and Health Studies.2025;[Epub] CrossRef - Influence of Continuous Rotation and Optimal Torque Reverse Kinematics on the Cyclic Fatigue Strength of Endodontic NiTi Clockwise Cutting Rotary Instruments

Jorge N. R. Martins, Emmanuel J. N. L. Silva, Duarte Marques, Marco A. Versiani

Dentistry Journal.2024; 12(10): 317. CrossRef - Comparative Evaluation of the Cyclic Fatigue Resistance of WaveOne Gold in Reciprocation, ProGlider in Rotary Motion, and Manual Files in a Reciprocating Handpiece Within Simulated Curved Canals: An In Vitro Study

Shivangi M Pujara, Hardik B Shah, Leena H Jobanputra

Cureus.2024;[Epub] CrossRef - The extended finite element method in endodontics: A scoping review and future directions for cyclic fatigue testing of nickel–titanium instruments

Philip Yuan‐Ho Chien, Laurence James Walsh, Ove Andreas Peters

Clinical and Experimental Dental Research.2024;[Epub] CrossRef - Evaluatation of two nickle-titanium systems’ (Neolix and X Pro Gold) resistance to fracture after immersion in sodium hypochlorite.

Solmaz Araghi, Abbas Delvarani, Faeze dehghan, Parisa Kaghazloo

journal of research in dental sciences.2024; 21(1): 17. CrossRef - Characterization of the file‐specific heat‐treated ProTaper Ultimate rotary system

Jorge N. R. Martins, Emmanuel João Nogueira Leal Silva, Duarte Marques, Natasha Ajuz, Mário Rito Pereira, Rui Pereira da Costa, Francisco Manuel Braz Fernandes, Marco Aurélio Versiani

International Endodontic Journal.2023; 56(4): 530. CrossRef - Influence of different heat treatments and temperatures on the cyclic fatigue resistance of endodontic instruments with the same design

Walid Nehme, Alfred Naaman, Franck Diemer, Maria Laura Leotta, Giusy Rita Maria La Rosa, Eugenio Pedullà

Clinical Oral Investigations.2022; 27(4): 1793. CrossRef - Analysis of cyclic fatigue resistance of ProTaper Universal and ProTaper Next rotary instruments

Nenad Stosic, Jelena Popovic, Marija Andjelkovic-Apostolovic, Aleksandar Mitic, Radomir Barac, Marija Nikolic, Marko Igic

Stomatoloski glasnik Srbije.2022; 69(3): 109. CrossRef - What Meaningful Information Are the Instruments Mechanical Testing Giving Us? A Comprehensive Review

Jorge N.R. Martins, Rui F. Martins, Francisco Manuel Braz Fernandes, Emmanuel J.N.L. Silva

Journal of Endodontics.2022; 48(8): 985. CrossRef - Metallurgical Tests in Endodontics: A Narrative Review

Alessio Zanza, Marco Seracchiani, Rodolfo Reda, Gabriele Miccoli, Luca Testarelli, Dario Di Nardo

Bioengineering.2022; 9(1): 30. CrossRef - A Comparative Study of Four different Contemporary NiTi Rotary Endodontic Files by Metallurgical and Mechanical Analysis with Energy-dispersive X-ray Spectrophotometry with FE-SEM and Cyclic Fatigue Resistance Evaluation

Akash Azad, Shraddha Chokshi

Journal of Research and Advancement in Dentistry.2022; 14(1): 21. CrossRef - Impact of Peracetic Acid on the Dynamic Cyclic Fatigue of Heat-Treated Nickel-Titanium Rotary Endodontic Instrument

Suhad Jabbar Hamed Al-Nasrawi, Zuha Ayad Jaber, Nibrass Talib Al-Quraine, Abtesam Imhemed Aljdaimi, Sattar Jabbar Abdul-Zahra Al-Hmedat, Saleh Zidan, Julfikar Haider, Luca Testarelli

International Journal of Dentistry.2021; 2021: 1. CrossRef - Influence of shaft length on torsional behavior of endodontic nickel–titanium instruments

Gianluca Gambarini, Marco Seracchiani, Alessio Zanza, Gabriele Miccoli, Andrea Del Giudice, Luca Testarelli

Odontology.2021; 109(3): 568. CrossRef - Cyclic Fatigue Resistance of Nickel-titanium Rotary Instruments according to the Angle of File Access and Radius of Root Canal

Eugenio Pedullà, Giusy Rita Maria La Rosa, Chiara Virgillito, Ernesto Rapisarda, Hyeon-Cheol Kim, Luigi Generali

Journal of Endodontics.2020; 46(3): 431. CrossRef - Torsional Resistance of Two New Heat Treated Nickel Titanium Rotary Instruments: An in Vitro Evaluation

Gianluca Gambarini, Gabriele Miccoli, Dario Di Nardo, Andrea Del Giudice, Alessandro Mazzoni, Marco Seracchiani, Luca Testarelli

Pesquisa Brasileira em Odontopediatria e Clínica Integrada.2020;[Epub] CrossRef - Influence of heat treatment on torsional resistance and surface roughness of nickel‐titanium instruments

E. J. N. L. Silva, J. F. N. Giraldes, C. O. de Lima, V. T. L. Vieira, C. N. Elias, H. S. Antunes

International Endodontic Journal.2019; 52(11): 1645. CrossRef

-

235

View

-

8

Download

-

16

Crossref

|