Search

- Page Path

- HOME > Search

- Comparison of bond strengths of ceramic brackets bonded to zirconia surfaces using different zirconia primers and a universal adhesive

- Ji-Yeon Lee, Jaechan Ahn, Sang In An, Jeong-won Park

- Restor Dent Endod 2018;43(1):e7. Published online January 22, 2018

- DOI: https://doi.org/10.5395/rde.2018.43.e7

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives The aim of this study is to compare the shear bond strengths of ceramic brackets bonded to zirconia surfaces using different zirconia primers and universal adhesive.

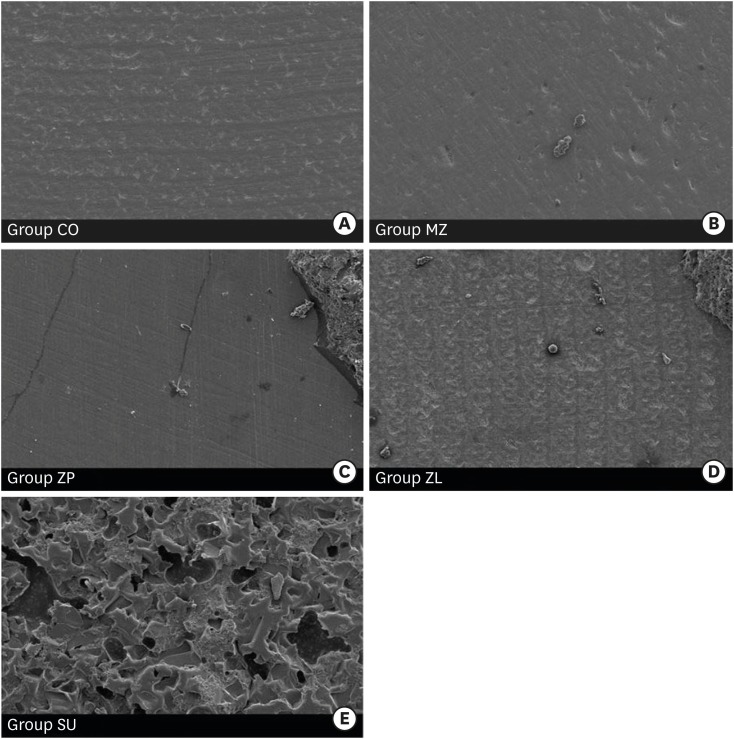

Materials and Methods Fifty zirconia blocks (15 × 15 × 10 mm, Zpex, Tosoh Corporation) were polished with 1,000 grit sand paper and air-abraded with 50 µm Al2O3 for 10 seconds (40 psi). They were divided into 5 groups: control (CO), Metal/Zirconia primer (MZ, Ivoclar Vivadent), Z-PRIME Plus (ZP, Bisco), Zirconia Liner (ZL, Sun Medical), and Scotchbond Universal adhesive (SU, 3M ESPE). Transbond XT Primer (used for CO, MZ, ZP, and ZL) and Transbond XT Paste was used for bracket bonding (Gemini clear ceramic brackets, 3M Unitek). After 24 hours at 37°C storage, specimens underwent 2,000 thermocycles, and then, shear bond strengths were measured (1 mm/min). An adhesive remnant index (ARI) score was calculated. The data were analyzed using one-way analysis of variance and the Bonferroni test (

p = 0.05).Results Surface treatment with primers resulted in increased shear bond strength. The SU group showed the highest shear bond strength followed by the ZP, ZL, MZ, and CO groups, in that order. The median ARI scores were as follows: CO = 0, MZ = 0, ZP = 0, ZL = 0, and SU = 3 (

p < 0.05).Conclusions Within this experiment, zirconia primer can increase the shear bond strength of bracket bonding. The highest shear bond strength is observed in SU group, even when no primer is used.

-

Citations

Citations to this article as recorded by- Effectiveness of universal adhesives for orthodontic bonding to enamel and restorative materials: A systematic review

Claire-Adeline Dantagnan, Maureen Boudrot, Julia Bosco, Gauthier Dot, Ali Nassif, Philippe François, Jean-Pierre Attal

International Orthodontics.2026; 24(2): 101089. CrossRef - State-of-the-Art Zirconia and Glass–Ceramic Materials in Restorative Dentistry: Properties, Clinical Applications, Challenges, and Future Perspectives

Sorin Gheorghe Mihali, Adela Hiller

Applied Sciences.2025; 15(23): 12841. CrossRef - Shear bond strength and ARI scores of metal brackets to glazed glass ceramics and zirconia: an in vitro study investigating surface treatment protocols

Claire Pédemay, Philippe François, Vincent Fouquet, Sarah Abdel-Gawad, Jean-Pierre Attal, Claire-Adeline Dantagnan

BMC Oral Health.2024;[Epub] CrossRef - Impact of different pretreatments and attachment materials on shear bond strength of indirectly bonded brackets using CAD/CAM transfer trays to monolithic zirconia

Rebecca Jungbauer, Christian M. Hammer, Daniel Edelhoff, Peter Proff, Bogna Stawarczyk

Dental Materials.2023; 39(2): 170. CrossRef - Mechanical and chemical surface treatment enhances bond strength between zirconia and orthodontic brackets: an in vitro study

Nareudee Limpuangthip, Atikom Surintanasarn, Ploylada Vitavaspan

BDJ Open.2023;[Epub] CrossRef - Effect of Different Surface Treatments and Orthodontic Bracket Type on Shear Bond Strength of High‐Translucent Zirconia: An In Vitro Study

Yasamin Babaee Hemmati, Hamid Neshandar Asli, Mehran Falahchai, Sina Safary, Sandrine Bittencourt Berger

International Journal of Dentistry.2022;[Epub] CrossRef - Does Surface Treatment With Different Primers Increase The Shear Bond Strength Between Metallic Bracket and Monolithic Zirconia?

Emine Begüm BÜYÜKERKMEN, Ayşe Selenge AKBULUT, Murat KEÇECİ

Selcuk Dental Journal.2022; 9(2): 451. CrossRef - Effect of Different Surface Treatments on the Surface Roughness and Orthodontic Bond Strength of Partially-stabilized Zirconia

Mustafa Borga Dönmez, Betül Ballı Demirel, Münir Demirel, Yasemin Gündoğdu, Hamdi Şükür Kılıç

Meandros Medical and Dental Journal.2022; 23(3): 335. CrossRef - Shear Bond Strength of Polypropylene Fiber in Orthodontic Adhesive on Glazed Monolithic Zirconia

Dhanabhol Riowruangsanggoon, Apiwat Riddhabhaya, Nattisa Niyomtham, Irin Sirisoontorn

Polymers.2022; 14(21): 4627. CrossRef - Effects of Three Novel Bracket Luting Agents Containing Zirconia Primer on Shear Bond Strength of Metal Orthodontic Brackets Attached to Monolithic Zirconia Crowns: A Preliminary In Vitro Study

Milad Shamohammadi Heidari, Mehrnaz Moradinejad, Hamed Tabatabaei, Vahid Rakhshan, Dinesh Rokaya

International Journal of Dentistry.2022;[Epub] CrossRef - Impact of different pretreatments and attachment materials on shear bond strength between monolithic zirconia restorations and metal brackets

Rebecca Jungbauer, Peter Proff, Daniel Edelhoff, Bogna Stawarczyk

Scientific Reports.2022;[Epub] CrossRef - Bracket Bonding to All-Ceramic Materials with Universal Adhesives

Cecilia Goracci, Giuseppe Di Bello, Lorenzo Franchi, Chris Louca, Jelena Juloski, Jovana Juloski, Alessandro Vichi

Materials.2022; 15(3): 1245. CrossRef - Effect of enamel-surface modifications on shear bond strength using different adhesive materials

Bo-wen Zheng, Shan Cao, Majedh Abdo Ali Al-Somairi, Jia He, Yi Liu

BMC Oral Health.2022;[Epub] CrossRef - The effect of various mechanical and chemical surface conditioning on the bonding of orthodontic brackets to all ceramic materials

Dalia A. Abuelenain, Amal I. Linjawi, Ahmed S. Alghamdi, Fahad M. Alsadi

Journal of Dental Sciences.2021; 16(1): 370. CrossRef - The Performance of Universal Adhesives on Orthodontic Bracket Bonding

Muhittin Ugurlu, Muhammed Hilmi Buyukcavus

European Journal of General Dentistry.2021; 10(01): 019. CrossRef - A comparison of shear bond strength of brackets bonded to zirconia

Hannah Knott, Xiaoming Xu, Edwin Kee, Qingzhao Yu, Paul Armbruster, Richard Ballard

Australasian Orthodontic Journal.2021; 37(1): 62. CrossRef - Influence of Surface Treatment and Resin Cements on the Bond Strength between the Y-TZP Zirconia and Composite Resin Interface

Lucas Campagnaro Maciel, Amanda Pádua Proeza, Hélyda Coelho Guimarães Balbino, Marcela Moráo Corteletti, Ricardo Huver De Jesus, Laís Regiane da Silva Concílio

Journal of Health Sciences.2019; 21(5): 477. CrossRef - Effect of Simplified Bonding on Shear Bond Strength between Ceramic Brackets and Dental Zirconia

Ga-Youn Ju, Soram Oh, Bum-Soon Lim, Hyun-Seung Lee, Shin Hye Chung

Materials.2019; 12(10): 1640. CrossRef

- Effectiveness of universal adhesives for orthodontic bonding to enamel and restorative materials: A systematic review

- 2,282 View

- 16 Download

- 18 Crossref

- Orthodontic bracket bonding to glazed full-contour zirconia

- Ji-Young Kwak, Hyo-Kyung Jung, Il-Kyung Choi, Tae-Yub Kwon

- Restor Dent Endod 2016;41(2):106-113. Published online April 14, 2016

- DOI: https://doi.org/10.5395/rde.2016.41.2.106

-

Abstract

Abstract

PDF

PDF PubReader

PubReader ePub

ePub Objectives This study evaluated the effects of different surface conditioning methods on the bond strength of orthodontic brackets to glazed full-zirconia surfaces.

Materials and Methods Glazed zirconia (except for the control, Zirkonzahn Prettau) disc surfaces were pre-treated: PO (control), polishing; BR, bur roughening; PP, cleaning with a prophy cup and pumice; HF, hydrofluoric acid etching; AA, air abrasion with aluminum oxide; CJ, CoJet-Sand. The surfaces were examined using profilometry, scanning electron microscopy, and electron dispersive spectroscopy. A zirconia primer (Z-Prime Plus, Z) or a silane primer (Monobond-S, S) was then applied to the surfaces, yielding 7 groups (PO-Z, BR-Z, PP-S, HF-S, AA-S, AA-Z, and CJ-S). Metal bracket-bonded specimens were stored in water for 24 hr at 37℃, and thermocycled for 1,000 cycles. Their bond strengths were measured using the wire loop method (

n = 10).Results Except for BR, the surface pre-treatments failed to expose the zirconia substructure. A significant difference in bond strengths was found between AA-Z (4.60 ± 1.08 MPa) and all other groups (13.38 ± 2.57 - 15.78 ± 2.39 MPa,

p < 0.05). For AA-Z, most of the adhesive remained on the bracket.Conclusions For bracket bonding to glazed zirconia, a simple application of silane to the cleaned surface is recommended. A zirconia primer should be used only when the zirconia substructure is definitely exposed.

-

Citations

Citations to this article as recorded by- Evaluation of Different Surface Roughening Techniques on Clear Aligner Attachments Bonded to Monolithic Zirconia: In Vitro Study

Nehal F Albelasy, Ahmad M Hafez, Abdullah S Alhunayni

The Journal of Contemporary Dental Practice.2025; 25(12): 1104. CrossRef - An Innovative Method of Permanent Retention on Veneered Crowns

Yugandhar Garlapati, Sampath Krishna Veni, Jashva Vamsi Kogila, Polisetty Siva Krishna, K. N. Anand Kumar

Journal of Indian Orthodontic Society.2025; 59(3): 279. CrossRef - Effect of Different Primers on the Shear Bond Strength of Orthodontic Brackets Bonded to Reinforced Polyetheretherketone (PEEK) Substrate

Ahmed Akram EL-Awady, Khaled Samy ElHabbak, Hussein Ramadan Mohamed, Ahmed Elsayed Elwan, Karim Sherif Adly, Moamen Ahmed Abdalla, Ehab Mohamed Kamal, Ahmed Leithy Alameldin

Dentistry Journal.2024; 12(6): 188. CrossRef - The Effect of Various Lasers on the Bond Strength Between Orthodontic Brackets and Dental Ceramics: A Systematic Review and Meta-Analysis

Seyed Ali Mosaddad, Jaafar Abduo, Mehrnaz Zakizade, Hamid Tebyaniyan, Ahmed Hussain

Photobiomodulation, Photomedicine, and Laser Surgery.2024; 42(1): 20. CrossRef - Shear Bond Strength of Clear Aligner Attachment Using 4-META/MMA-TBB Resin Cement on Glazed Monolithic Zirconia

Kasidit Nitasnoraset, Apiwat Riddhabhaya, Chidchanok Sessirisombat, Hitoshi Hotokezaka, Noriaki Yoshida, Irin Sirisoontorn

Polymers.2024; 16(14): 1988. CrossRef - Orthodontic bonding in special circumstances

Angus Burns, Annie Hughes, Michael O’Sullivan

British Dental Journal.2024; 237(5): 400. CrossRef - Bonding Effectiveness of Saliva-Contaminated Monolithic Zirconia Ceramics Using Different Decontamination Protocols

Necla Demir, Ozge Genc, Ipek Balevi Akkese, Meral Arslan Malkoc, Mutlu Ozcan, Konstantinos Michalakis

BioMed Research International.2024; 2024: 1. CrossRef - Comparison of shear bond strength of metallic orthodontic brackets bonded to zirconia models underwent different surface conditioning methods and different primer systems

Amena Raafat Khaled, Enas Talb Al-Jwary

APOS Trends in Orthodontics.2024; 15: 251. CrossRef - Shear bond strength and ARI scores of metal brackets to glazed glass ceramics and zirconia: an in vitro study investigating surface treatment protocols

Claire Pédemay, Philippe François, Vincent Fouquet, Sarah Abdel-Gawad, Jean-Pierre Attal, Claire-Adeline Dantagnan

BMC Oral Health.2024;[Epub] CrossRef - Enhanced Bracket Retention on Reinforced Polyetheretherketone: Role of Specialized Primers in Shear Bond Strength

Mehmet Yılmaz, Ayşe Demir

International Journal of Dental Research and Allied Sciences.2024; 4(2): 64. CrossRef - Mechanical and chemical surface treatment enhances bond strength between zirconia and orthodontic brackets: an in vitro study

Nareudee Limpuangthip, Atikom Surintanasarn, Ploylada Vitavaspan

BDJ Open.2023;[Epub] CrossRef - Shear bond strength of orthodontic brackets bonded to a new version of zirconium all ceramic restoration: An in vitro comparative study

Assem Abd EL-wahab, Marwa Shamaa, Ahmed Hafez, Noha El-Wassefy, Shaza Hammad

Heliyon.2023; 9(5): e16249. CrossRef - Evaluation of the effects of different composite materials and surface roughening techniques in bonding attachments of clear aligner on monolithic zirconia

Semiha Arslan, Hamiyet Kilinc

Orthodontics & Craniofacial Research.2023; 26(4): 546. CrossRef - Effect of Different Types of Adhesive Agents on Orthodontic Bracket Shear Bond Strength: A Cyclic Loading Study

Irfan Eser, Orhan Cicek, Nurhat Ozkalayci, Mehmet Yetmez, Hande Erener

Materials.2023; 16(2): 724. CrossRef - Bracket Bonding to All-Ceramic Materials with Universal Adhesives

Cecilia Goracci, Giuseppe Di Bello, Lorenzo Franchi, Chris Louca, Jelena Juloski, Jovana Juloski, Alessandro Vichi

Materials.2022; 15(3): 1245. CrossRef - Effects of Three Novel Bracket Luting Agents Containing Zirconia Primer on Shear Bond Strength of Metal Orthodontic Brackets Attached to Monolithic Zirconia Crowns: A Preliminary In Vitro Study

Milad Shamohammadi Heidari, Mehrnaz Moradinejad, Hamed Tabatabaei, Vahid Rakhshan, Dinesh Rokaya

International Journal of Dentistry.2022;[Epub] CrossRef - Does Surface Treatment With Different Primers Increase The Shear Bond Strength Between Metallic Bracket and Monolithic Zirconia?

Emine Begüm BÜYÜKERKMEN, Ayşe Selenge AKBULUT, Murat KEÇECİ

Selcuk Dental Journal.2022; 9(2): 451. CrossRef - Effect of different primer agents on shear bond strength of ceramic orthodontic brackets bonded to zirconia ceramics

Ebru Kucukkaraca, Canan Akay

Journal of the Australian Ceramic Society.2022; 58(2): 645. CrossRef - Shear Bond Strength of Polypropylene Fiber in Orthodontic Adhesive on Glazed Monolithic Zirconia

Dhanabhol Riowruangsanggoon, Apiwat Riddhabhaya, Nattisa Niyomtham, Irin Sirisoontorn

Polymers.2022; 14(21): 4627. CrossRef - Bond Integrity and Surface Topography of Orthodontic Metal Brackets to Ceramic and Polymer-Based Restorations. An In-Vitro Study Design

Ali Alqerban

Science of Advanced Materials.2021; 13(4): 650. CrossRef - The effect of surface treatment and thermocycling on the shear bond strength of orthodontic brackets to the Y-TZP zirconia ceramics: A systematic review

Tamzid AHMED, Nashid FAREEN, Mohammad Khursheed ALAM

Dental Press Journal of Orthodontics.2021;[Epub] CrossRef - Orthodontic Bonding: Review of the Literature

Ali H. Alzainal, Ahmed Shehab Majud, Abdulfatah M. Al-Ani, Adil O. Mageet

International Journal of Dentistry.2020; 2020: 1. CrossRef - Shear bond strength between orthodontic metal brackets and Y-TZP according to the various ceramic surface treatments before and after thermocycling

Ji-Bong Choi, Seon-Mi Byeon

Korean Journal of Dental Materials.2020; 47(2): 83. CrossRef - Bond Strength and Failure Pattern of Orthodontic Tubes Adhered to a Zirconia Surface Submitted to Different Modes of Application of a Ceramic Primer

Francisco da Silva Araújo Milagres, Dauro Douglas Oliveira, Giordani Santos Silveira, Emanuelle de Fátima Ferreira Oliveira, Alberto Nogueira da Gama Antunes

Materials.2019; 12(23): 3922. CrossRef - Shear bond strength of orthodontic brackets bonded to a new all-ceramic crown composed of lithium silicate infused with zirconia: An in vitro comparative study

Ryan Gardiner, Richard Ballard, Qingzhao Yu, Edwin Kee, Xiaoming Xu, Paul Armbruster

International Orthodontics.2019; 17(4): 726. CrossRef - Comparison of bond strengths of ceramic brackets bonded to zirconia surfaces using different zirconia primers and a universal adhesive

Ji-Yeon Lee, Jaechan Ahn, Sang In An, Jeong-won Park

Restorative Dentistry & Endodontics.2018;[Epub] CrossRef

- Evaluation of Different Surface Roughening Techniques on Clear Aligner Attachments Bonded to Monolithic Zirconia: In Vitro Study

- 2,034 View

- 12 Download

- 26 Crossref

KACD

KACD

First

First Prev

Prev