Wear of contemporary dental composite resin restorations: a literature review

Article information

Abstract

Composite resins are the most commonly used dental restorative materials after minimally invasive dental procedures, and they offer an aesthetically pleasing appearance. An ideal composite restorative material should have wear properties similar to those of tooth tissues. Wear refers to the damaging, gradual loss or deformation of a material at solid surfaces. Depending on the mechanism of action, wear can be categorized as abrasive, adhesive, fatigue, or corrosive. Currently used composite resins cover a wide range of materials with diverse properties, offering dental clinicians multiple choices for anterior and posterior teeth. In order to improve the mechanical properties and the resistance to wear of composite materials, many types of monomers, silane coupling agents, and reinforcing fillers have been developed. Since resistance to wear is an important factor in determining the clinical success of composite resins, the purpose of this literature review was to define what constitutes wear. The discussion focuses on factors that contribute to the extent of wear as well as to the prevention of wear. Finally, the behavior of various types of existing composite materials such as nanohybrid, flowable, and computer-assisted design/computer-assisted manufacturing materials, was investigated, along with the factors that may cause or contribute to their wear.

INTRODUCTION

Composite resins are the most commonly used dental restorative materials, following the principles of minimally invasive dentistry and offering an aesthetically pleasing appearance. Various types of composite restorations in the oral cavity have occlusal contact with each other, and continuous mastication forces inevitably lead to composite wear. An ideal composite restorative material should have wear properties similar to those of tooth tissues [1]. Under physiological conditions, enamel wear is approximately 0.02–0.04 mm of vertical loss per year [2]. If this amount of tooth wear increases and the wear rate accelerates, then pathological surface loss is defined as occurring, which poses a challenge for dental practitioners, as the impact of pathological surface loss could be severe and may influence patients' quality of life.

The technology of composite materials has advanced significantly in recent years, mainly due to the increased aesthetic demands of patients. Additionally, improvements in the physical and mechanical properties of composite materials, the increased familiarity of dental practitioners with these materials, and concerns regarding the use of amalgam have made composite resins more popular in dental practice [34]. Various changes in the composition of the composite resins have been implemented, including the use of reinforcing fillers, organic matrix, and coupling agents [3]. The most important modifications involve a reduced size of reinforcing fillers in order to produce composite materials with improved surface polishing and resistance to wear.

The wear of composite materials is a multifactorial phenomenon, as it depends on factors such as tooth characteristics, the type of material, the size of the cavity, the physiology of occlusion, and the nature of the opposing teeth [5]. Reinforcing fillers play a crucial role in restorative material, in terms of size, distribution, and volume content. Water absorption is an important parameter that negatively affects the strength of composite resin materials because it causes plasticization of the organic matrix and weakens the bonding of the reinforcing fillers with the organic matrix. As a result, the structure of the composite materials is degraded, which leads to faster hydrolytic decomposition due to the action of the enzymes in saliva [56].

Wear of composite resin restorations can be evaluated both in clinical and laboratory conditions. In clinical conditions, the methods of wear evaluation are further classified as direct and indirect [7]. Direct methods include observation of composite restorations in the oral cavity by a trained evaluator, mainly based on the United States Public Health Service criteria. Indirect methods require impressions of the restored teeth and fabrication of casts. Subsequently, the casts are evaluated by either qualitative methods such as Leinfelder and Moffa-Lugassy scales or quantitative methods through measurements of properties such as surface topography, surface roughness, material loss, and fractal dimension. These properties can be measured by mechanical (stylus profilometry and atomic force microscopy) or optical (laser scanning microscopy and white-light optical profilometry) systems. In laboratory conditions, the wear evaluation of composite restorations follows ISO/TS 14569 and is mainly conducted using profilometry after simulation of the mastication process [8].

Despite improvements in the mechanical properties of composite resins, wear is still a major problem, especially in patients with parafunctional activities, such as bruxism [9]. It has been estimated that in 2015 alone, 800 million composite resin restorations were placed worldwide, of which 80% were located on posterior teeth [10]. The same research also estimated that at least 5% of the restorations placed on posterior teeth failed due to fracture and 12% presented significant wear over a period of 10 years. About 77 million composite resin restorations on posterior teeth worldwide were likely to show significant wear, while approximately 32 million composite resin restorations placed in 2015 will need to be repaired or replaced due to fracture during the next 10 years [11].

Therefore, the aim of this literature review was to present modern views on the mechanisms of wear of composite resin materials and to compare the resistance to wear between different types of composite materials currently used in clinical practice.

TYPES OF WEAR OF COMPOSITE MATERIALS

Wear is the damaging, gradual loss or deformation of a material at solid surfaces. It is the result of the mechanical and/or chemical interactions with another surface in relative motion [12]. The study of wear and related processes is referred to as tribology. Together with other processes such as fatigue and creep, wear causes functional surfaces to degrade, leading to material failure or loss of functionality.

The magnitude of wear as a function of time is the wear rate, which is affected by factors such as the type of loading, type of motion, temperature, and lubrication of the surfaces [13]. There are 3 different stages of wear rate of a material:

1. The primary or early stage, where surfaces adapt to each other and the wear rate might vary between high and low.

2. The secondary or mid-age stage, where steady wear can be observed. Most of the component's operational life is spent in this stage.

3. The tertiary or old-age stage, where surfaces are subjected to rapid failure due to a high rate of wear.

Of note, the wear rate is significantly affected by the operating conditions and the formation of tribofilms. The secondary stage is shortened by changes in environmental conditions, such as higher temperatures, strain rates, and stresses [14]. Although the wear of materials is usually quantified in terms of weight loss and the wear rate, previous studies reported that the wear coefficient is more suitable because it takes the wear rate, the applied load, and the hardness of the wear pin into account [15]. The wear coefficient K in an abrasive model is defined as: K= 3HW/PLρ, where H is the Brinell hardness, W is the weight loss, P is the normal load, L is the sliding distance, and ρ is the density of the material [15].

The wear of the surface of a material depends mainly on 3 factors: a) the structure of the material, b) the conditions under the material comes in contact with the abrasive agent, and c) the environment of the material in relation with the nature of the surface [16171819]. Depending on the mechanism of action, wear can be categorized as 1) abrasive, 2) adhesive, 3) fatigue, and 4) corrosive [20].

Abrasive wear

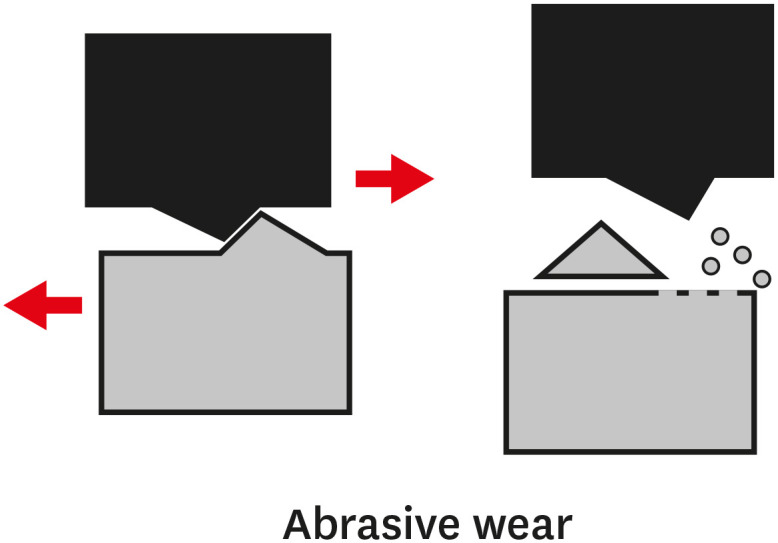

According to the American Society for Testing and Materials (ASTM) International, abrasive wear is the loss of a material due to hard protuberances or hard particles that are forced against and move along a solid surface [21]. During abrasive wear, the surface of the material is scraped off another surface, either by a hard protrusion or by hard particles between the 2 surfaces [22] (Figure 1).

Abrasive wear can be classified in terms of the type of contact and the contact environment [23]. The type of contact indicates the 2 modes of abrasive wear. The first type is called 2-body abrasive wear, while the second is called 3-body abrasive wear [24]. Two-body wear occurs when grit or hard particles remove material from the opposite surface. Three-body wear occurs when the particles are not constrained, and are free to roll and slide down a surface. The contact environment can be defined as open or closed. An open contact environment occurs when the surfaces are sufficiently displaced to be independent of one another.

The mechanisms of abrasive wear include a) plowing, b) cutting, and c) fragmentation. Plowing results in the formation of grooves, but cannot directly remove the material's volume. The displaced material creates ridges besides grooves, which may be removed by subsequent passage of abrasive particles. Cutting occurs when a material is separated from the surface in the form of primary debris without displacement to the sides of the grooves. Fragmentation takes place when a material is separated from a surface by a cutting process and the indenting abrasive induces topical fracture of the wear material [23].

Abrasive wear can be measured as loss of mass by the Taber abrasion test according to ISO 9352 or ASTM D 4060 [2425]. The wear volume (V) for single-abrasive wear can be described by the following equation: V = K × WL/H, where K is the wear coefficient, W is the load, L is the sliding distance, and H is the hardness of the material.

In clinical conditions, the abrasive wear caused by tooth brushing affects all exposed surfaces of a composite resin restoration, while abrasion caused by occlusal forces is limited to contact surfaces [26]. During mastication, both modes of abrasive wear are present; some areas of the opposing occlusal surfaces are scraped off between them (2-body abrasive wear), while others are scraped off by food particles that are inserted between the opposing teeth (3-body abrasive wear). It should also be noted that 2-body abrasive wear between opposing teeth involves the occlusal surface of a restoration with another tooth or restoration surface and should not be confused with attrition, which is the wear of occlusal surfaces of teeth as a result of functional or malfunctional tooth-to-tooth contact [26].

The abrasive wear observed in composite resin restorations is affected by various factors, such as the size, shape, content, orientation, and distribution of the reinforcing fillers, the type of monomers, which affect the degree of polymerization and as a result the hardness of the surface, as well as the bond between the organic and inorganic substances; if it is weak, it may lead to detachment of filler particles from the composite surface. All these factors are affected by the forces applied to the composite resin material during mastication, making the whole system very complicated [27].

Previous investigations demonstrated that the abrasive wear of a composite resin is reduced when the size of the fillers and the distance between them are reduced, when the degree of polymerization of the resin is increased, and when the strength of the bond between the fillers and the organic matrix is increased [1628]. The properties of the surface and the particles that cause abrasion also play an important role in the wear rate. If the composite resin is harder than the abrasive surface, the wear is much lower [29]. It is interesting to mention that in 2-body abrasive wear, angular protrusions cause more abrasion than rounded ones, even if they are less hard [30].

Adhesive wear

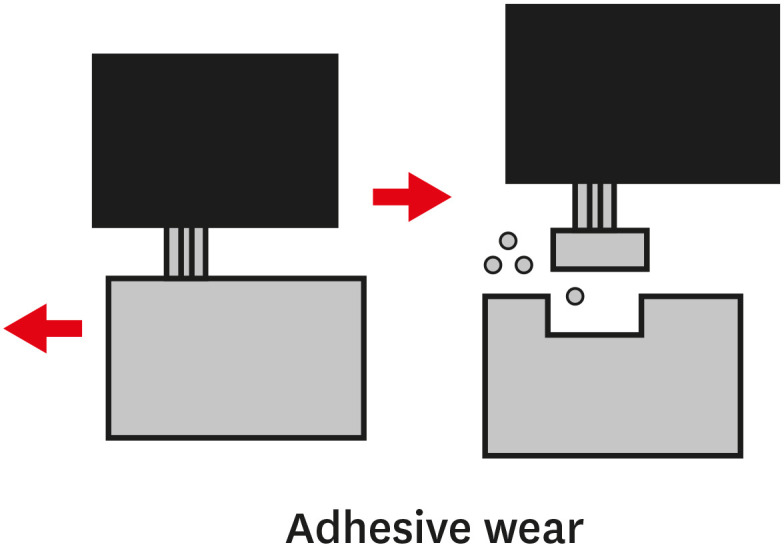

Adhesive wear occurs between 2 surfaces during frictional contact when unwanted displacement and attachment of wear debris or material compounds takes place from one surface to another [31] (Figure 2).

Adhesive wear can be classified into 2 types. The first type occurs when adhesive wear is caused by relative motion, and direct contact and plastic deformation result in the deposition of wear debris and material from one surface to another. The second type takes place when cohesive forces hold 2 surfaces together, although they are not in contact, with or without any actual disposition of material. Adhesive wear may lead to an increase in surface roughness and the creation of protrusions on the composite surface [32]. A simple model of the wear volume for adhesive wear can be described by the same equation as abrasive wear.

When the occlusal surfaces of antagonist teeth come in contact during mastication, welding may occur at the contact points of the surfaces [31]. When attempting to separate the 2 surfaces, shear forces are applied to the welding points, which can lead to the detachment of components from the composite resin surface and the induction of surface micro-fractures. The detached particles may be left loose on the surface or moved to the other surface. Small particles often form larger clusters, which may contribute to the abrasion of the surface (abrasive wear). Adhesive wear does not seem to contribute significantly to the abrasion of composite resin materials because saliva acts as a lubricant and significantly mitigates abrasion [33].

Fatigue wear

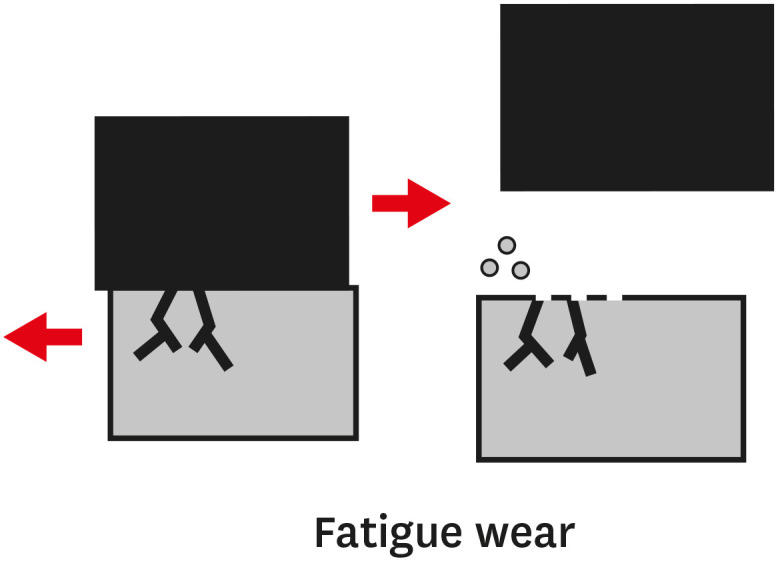

Fatigue wear occurs when a material is weakened by cycling loading. In particular, particles are detached from the material's surface after the application of cyclic forces, leading to the growth of microcracks, which may be either superficial or below the surface [34] (Figure 3).

As these cracks propagate, they can coalesce and remove small particles from the surface, which can cause 3-body abrasive wear. In clinical conditions, this abrasion is considered to occur during mastication, where opposing teeth come into contact repeatedly [35]. It has been argued that when a surface is rubbed against another, a compression zone is created ahead of the direction of movement and a tension zone is created behind the direction of movement. Repetition of these stresses on a material can cause fatigue wear [36].

Corrosive wear

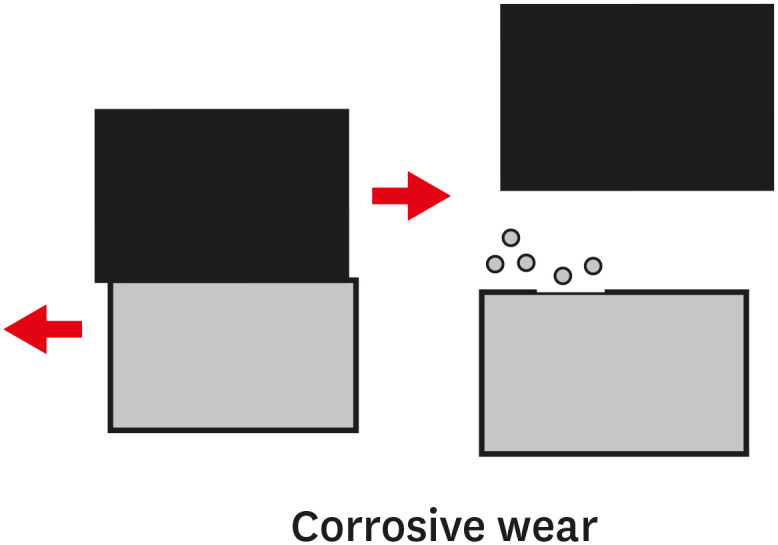

Corrosion is caused by a chemical reaction between a worn surface and the corroding medium [32] (Figure 4).

Corrosion occurs on both lubricated and dry surfaces by a synergistic action of tribological stresses. In the oral cavity, restorations are exposed to a variety of corrosive substances derived from food, beverages, bacteria, and saliva [19]. It has been claimed that all these corrosive substances are able to reduce surface hardness and increase the surface roughness of composite resins, resulting in increased susceptibility to abrasive wear [6]. In this aggressive environment, saliva works protectively by reducing the acidity of food and microbial activity through its buffering properties [6].

WEAR OF DIFFERENT DENTAL COMPOSITE RESIN MATERIALS

Modern dental composite materials have a wide variety of properties, and today they are almost the only aesthetic materials used for direct restorations of both anterior and posterior teeth [37]. Many laboratory studies have found that resistance to wear depends on the type and composition of the composite resin material. Composite resin materials include organic matrix, which consists of various monomers, a coupling agent, which bonds the fillers to the organic matrix, and various types of inorganic fillers. Restorations using composite resin materials are classified as direct and indirect restorations based on the method of placement. In direct restorations, the composite resin is placed in the cavity in 1 session by the dentist, while indirect restorations usually involve 2 sessions because the restoration is fabricated in the laboratory and then is placed on the tooth [37].

WEAR OF DIRECT COMPOSITE RESIN RESTORATIONS

It has been reported that the ratio of reinforcing fillers plays a very important role in the resistance to wear of conventional composite resin materials and that a higher content of fillers reduces wear. It has been demonstrated that although the wear of composite resins is mainly affected by the properties of the reinforcing fillers, the composition of the resin monomers also influences wear, which means that wear is a complex and multifactorial process [38]. The complexity of the mechanisms of wear has also been reported by more recent studies [3940].

Nanohybrid composite resins have a significant percentage of nano-sized (nm) reinforcing fillers. They contain a mixture of colloidal silicon particles (20–60 nm) with larger metal particles (100–2,500 nm). Another type of composite resins is referred to as nanofilled resins, which contain a more uniform size distribution of nano-particles (5–75 nm) and also agglomerated nano-particles (nanoclusters, sized 0.6–1.4 μm) [3541]. The content of reinforcing fillers in nanohybrid and nanofilled composite resins is up to 80 vol%. Nanofilled composite resins present good mechanical properties, improved surface characteristics, and less polymerization shrinkage [4243]. The distribution of the fillers in nanofilled composite resins exhibits great homogeneity within the mass of the resin, and the small size of the fillers provides a greater contact surface between them and the organic matrix [44].

During mastication, the rigid fillers deliver the mastication forces to the more elastic organic matrix [45]. This may increase the tension at the bonding interface between the fillers and the organic matrix, which may lead to the displacement of the fillers and exposure of the more vulnerable organic matrix, resulting in wear of the material [46]. Clinical trials performed on posterior teeth restorations found no significant difference in the wear rate between conventional and nanofilled composite resins. On the contrary, in vitro studies reported that some nanofilled composite resins may present greater resistance to wear [4546].

In 1996 a new type of composite resins was introduced with low viscosity, known as “flowable” composite resins. In early years, these materials presented many disadvantages attributable to a very low content of reinforcing fillers ranging between 25 and 30 vol%, which resulted in low viscosity, but also in high polymerization shrinkage and less favorable physical and mechanical properties. Advanced formulations of flowable composite resins have improved their physical and mechanical properties due to changes in the composition of the organic matrix, increased content of reinforcing fillers (45–65 vol%) and modifications of the filler size [47]. As a result, contemporary flowable composite resins are indicated even for conservative restorations of posterior teeth [48].

A recent clinical study found that conventional and flowable composite resins showed similar clinical behavior after 2 years, when placed in occlusal class I cavities where the isthmus width was less than one-half of the intercuspal distance [49]. Moreover, an in vitro study comparing a flowable and a nanofilled composite resin found that the resistance to wear of both materials was similar [50]. In another study, the authors concluded that in contrast to the conventional composite resins, the size of the reinforcing fillers of the flowable composite resins may play a more important role in the magnitude of wear than the physical properties of the organic matrix [51].

In recent years, novel composite resins have been developed, such as those reinforced with synthetic fibers, bulk fill composite resins, silorane-based composite materials, and ormocers [52535455]. Nevertheless, there is insufficient information regarding their behavior in the oral environment and their resistance to wear in order to make credible conclusions.

WEAR OF INDIRECT COMPOSITE RESIN RESTORATIONS

Direct restorations with composite resin materials are completed in 1 visit, which is an advantage compared to indirect restorations, which require at least 2 visits. However, a major disadvantage of direct composite restorations is their shrinkage during polymerization, which is around 2–4%. In contrast, in indirect restorations the contraction stresses are limited to a small surface occupied by the luting cement between the tooth and the restoration [3]. Another disadvantage of direct restorations is the internal stresses created during polymerization shrinkage, which tend to detach the composite material from the walls of the cavity and may be 13 times larger than those of indirect restorations [56].

Contemporary indirect composite restorations are fabricated in laboratories with light, temperature, humidity, pressure, and time control systems that are able to provide an increased degree of polymerization, lower polymerization shrinkage stresses, and improved mechanical properties [575859]. Although in vitro studies reported that indirect composite restorations exhibited superior mechanical properties than direct composite restorations, their effectiveness in clinical practice is questionable. Indeed, it has been found that the survival rate of direct posterior composite restorations is similar to that of indirect restorations [606162]. In a recent in vitro study, the authors compared the resistance to wear of composite resins for indirect restorations with that for direct restorations. The results showed that there were no significant differences in wear resistance among the different types of composite resins [63]. The longevity of indirect composite restorations is a very important factor for the choice of treatment. The choice of a resin cement for the bonding of the composite materials to the tooth structures is crucial and it has been claimed that an increased resistance of the cement to wear contributes to the survival rates of restorations [64656667].

WEAR OF COMPOSITE CAD/CAM MATERIALS

A special category of composite resin materials for indirect restorations is computer-aided design/computer-aided manufacturing (CAD/CAM) materials, the clinical application of which has increased significantly in recent years [686970]. CAD/CAM technology was developed to improve the strength and aesthetics of tooth restorations, as well as to make the techniques easier, faster, and more accurate [71]. In particular, digital impressions are taken with a special scanning camera and the restoration is constructed by a milling machine. CAD/CAM machines can mill restorations comprising both composite resin and ceramic materials. The quality of CAD/CAM restorations is high because measurements and construction are very accurate due to the advanced digital technology [72]. Nevertheless, there are also some shortcomings, such as the cost of the equipment and training [73].

CAD/CAM composites can be categorized into composite resins with dispersed fillers and polymer infiltrated ceramic networks (PICN) [74]. The first category contains basic monomers such as Bis-GMA, UDMA, and TEGDMA and dispersed fillers such as silica, zirconia, and barium glass [75]. PICN materials consist of a 3-dimensional ceramic network that is infiltrated with a monomer mixture, presenting a higher Weibull modulus and making the material less brittle than glass ceramics [76].

CAD/CAM composite materials are manufactured with polymerization under high pressure and high temperature, resulting in improved mechanical properties [76]. It has been found that the wear of CAD/CAM composite materials was less than that of ceramic materials, and they induced less enamel abrasion of the opposing teeth than ceramic materials [77]. Additionally, CAD/CAM composite materials present lower wear than composite resins for direct restorations [7879].

There is now a need for composite resin materials with higher wear resistance in order to maintain their morphology for a longer period of time. This goal can be achieved through more research focusing on the development of improved and more durable monomers leading to better polymerization rates [80]. Research should also be directed towards technologies to manufacture reinforcing fillers with better distribution and shape, more stable bonds with the organic matrix [81], and self-repairing abilities [82].

CONCLUSIONS

Dealing with the wear of composite resin materials is challenging due to a lack of adequate knowledge and complexity of the mechanisms of action. The results of in vitro studies of composite resin wear should be considered with caution because wear in the oral cavity is a complex phenomenon that is very difficult to reproduce in laboratory conditions. Furthermore, future studies should focus more on improving the wear resistance of composite materials by changing their properties to be more similar to tooth tissues. The development of new adhesive strategies such as universal adhesive systems may contribute to this goal.

Notes

Conflict of Interest: No potential conflict of interest relevant to this article was reported.

Author Contributions:

Conceptualization: Dionysopoulos D.

Data curation: Dionysopoulos D, Gerasimidou O.

Formal analysis: Dionysopoulos D.

Investigation: Dionysopoulos D, Gerasimidou O.

Methodology: Dionysopoulos D, Gerasimidou O.

Project administration: Dionysopoulos D.

Resources: Dionysopoulos D.

Software: Gerasimidou O.

Supervision: Dionysopoulos D.

Validation: Dionysopoulos D.

Visualization: Dionysopoulos D.

Writing - original draft: Dionysopoulos D, Gerasimidou O.

Writing - review & editing: Dionysopoulos D, Gerasimidou O.