The study of fractural behavior of repaired composite

Article information

Abstract

Objectives

This study evaluated microtensile bond strength (µTBS) and short-rod fracture toughness to explain fractural behavior of repaired composite restorations according to different surface treatments.

Materials and Methods

Thirty composite blocks for µTBS test and sixty short-rod specimens for fracture toughness test were fabricated and were allocated to 3 groups according to the combination of surface treatment (none-treated, sand blasting, bur roughening). Each group was repaired immediately and 2 weeks later. Twenty-four hours later from repair, µTBS and fracture toughness test were conducted. Mean values analyzed with two-way ANOVA / Tukey's B test (α = 0.05) and correlation analysis was done between µTBS and fracture toughness. FE-SEM was employed on fractured surface to examine the crack propagation.

Results

The fresh composite resin showed higher µTBS than the aged composite resin (p < 0.001). Mechanically treated groups showed higher bond strength than non-mechanically treated groups except none-treated fresh group in µTBS (p < 0.05). The fracture toughness value of mechanically treated surface was higher than that of non-mechanically treated surface (p < 0.05). There was no correlation between fracture toughness and microtensile bond strength values. Specimens having high KIC showed toughening mechanism including crack deviation, microcracks and crack bridging in FE-SEM.

Conclusions

Surface treatment by mechanical interlock is more important for effective composite repair, and the fracture toughness test could be used as an appropriate tool to examine the fractural behavior of the repaired composite with microtensile bond strength.

Introduction

Resin-based composites are widely used in restorative dentistry with the development of more wear-resistant formulations, better adhesives, and improved light-curing and surface-sealing systems. Nevertheless, because of fractures or failures in composite restorations, clinicians must decide whether to replace or simply repair these restorations. The complete removal of partially defective composite restorations may be time-consuming and highly risky to remove sound tooth substance, and to injure the pulp tissue. Therefore, instead of its removal, the repair of defected restorations would be a favorable treatment option.

The oxygen-inhibition layer is not necessary when bonding additional layers of resin composites, at least for the initial 24 hours in which the remaining free radicals within the polymerized composite enables its chemical coupling to the repaired composite.1,2 However, when free radicals are reduced by aging, polishing or abrasion, surface treatment of composite is required for better repair bond strength between the existing composite and the new composite added.3 Various kinds of surface treatments have been suggested including diamond bur roughening and air abrasion. While they promote mechanical interlock, use of intermediate coupling agents improves surface wettability and chemical bonding to the cross-linked polymer matrix and/or filler particles of the old composite.4,5 Previous studies showed that use of unfilled low-viscosity intermediate resin could improve the bonding irrespective of the surface texture created by different surface treatments.6-8 Phosphoric acid seems to have just superficial cleaning effect of the composite surface and have no influence on the repair bond strength.1,5,9,10

Up to date, most studies of composite repair have been accomplished regarding the evaluation of bond strength. Especially, microtensile bond strength (µTBS) has been useful because of its better stress distribution at the true interface, the controlled substrate variables, and so on. However, although measuring the bond strength is one of the most common tests for assessing fractural behavior of repaired composite, it is very sensitive to condition and depends on the size of the cracks occurred during processing, producing and handling.11 Moreover, when substrate fractures occur, results of bond strength test become a measurement of the materials strength properties rather than actual integrity of the bonded interface. Therefore, the bond strength test alone is not sufficient to decide whether a treatment has enhanced the resistance to fracture or not.12,13 A reliable and valid method for the evaluation of bonded interfaces is needed to help predict, understand and assess clinical bonding failures.

Composite is a brittle material to which linear elastic fracture mechanics can be applied to analyze the stress state of the material at fracture.14 It would be more reasonable to evaluate fractural behavior by means of fracture toughness, especially when the failure of restoration is related to crack propagation originating from defects of interfacial surface. The plane-strain fracture toughness, determined by standard tests described by ASTM-E399, is defined as the resistance of a material to rapid crack propagation. It is an intrinsic property and is independent of the size of the initiating crack. In addition, it is considered to be a better measure of fracture resistance than other strength parameters, if a linear-elastic deformation to failure can be assumed.15 Fracture toughness can be characterized by one parameter, KIC which means critical stress intensity factor when tensile load is in-plane shear.16

There are various testing methods for examining the fracture toughness (KIC) of dental composites including single-edge notched beam method, compact tension method, short-rod with chevron notch method, double torsion method and so on. Among those, the short-rod fracture toughness test specimen, proposed by Barker,17 does not require fatigue pre-cracking. Stable crack growth occurs initially, and assessment of KIC is based on measurement of the load required for crack growth instability to occur.15 Its geometry contains a chevron-shaped bonding area designed to develop a significant stress concentration at the interface. Bond failure occurs along the midplane of the specimen where the bonded interface is located. This corresponds to the more usually observed failure mode in clinical practice. Therefore, the short-rod fracture toughness specimen would provide more clinically relevant information than the tensile or shear bond strength specimen. It is well-suited to the investigation of factors such as surface treatment which affects the adhesion of one material to another.16,18

To date, there have been some data about the fracture toughness of dentin-composite adhesive interface. However, data about fracture toughness of composite- composite repair interface have been rare. The objectives of this study were to determine the correlation between µTBS and KIC in composite repair and to explain fractural behavior of repaired composite depending on different surface treatments.

Materials and Methods

1. Experimental Materials

The materials used in this study are listed in Table 1.

2. Microtensile bond strength

1) Specimen preparation

Thirty cylinder-shaped blocks, 8 mm in height and 8 mm in diameter, were fabricated by layering 2-mm-thick increments of Gradia Direct Anterior (shade NT, GC; Tokyo, Japan) using a silicone mold. Each increment was carefully condensed with a clean plastic filling instrument in order to avoid contamination and/or incorporation of voids, then cured for 20s with the tip of the light curing unit (WBL-100 Santafe, S-Denti Co., LTD, Korea) placed in contact with the surface of the mold. The last increment was covered with polyester strip and compressed by slide glass in order to obtain a flat surface of the specimen after light curing. All composite blocks were allocated to 3 groups according to the surface treatment (nonetreated, sand blasting and diamond bur roughening) and each group was divided by aging time (fresh and 2 weeks aging). They were stored in artificial saliva at 37℃ before the repair procedure was performed.

2) Surface treatment and repair procedure

Fresh groups were repaired as follows within 30 minutes and aged groups were repaired 2 weeks since blocks had been made.

Group NF: There was no mechanical surface treatment. 35% Scotchbond Etchant gel (Ivoclar Vivadent; Schaan, Liechtenstein) was applied to the saliva-contaminated composite surface for 30s.

Group SF: Each composite block was sandblasted for 10s using 25-50 µm Al2O3 particles with Basic professional No. 2942 (Renfert GmbH, Hilzingen, Germany) at 5 mm from the surface (pressure of 60 psi) and etched as group 1.

Group BF: A coarse diamond chamfer bur was used to roughen the surface of each specimen for 10s at high speed with constant water spray. Then, the surface was etched as group 1.

Group NA: The same procedure to Group NF was performed on 2 weeks aged composite.

Group SA: The same procedure to Group SF was performed on 2 weeks aged composite.

Group BA: The same procedure to Group BF was performed on 2 weeks aged composite.

Each composite block was rinsed for 30s using a stream of oil-free compressed air/water from a syringe tip. An air syringe was then used for 5s to remove excess surface water. Two-step total etch bonding agent, Adper Single bond 2 (SB; 3M ESPE, St. Paul, USA) was applied twice, dried gently with air syringe for 5s to evaporate solvents and light-cured according to the manufacturer's recommendation. After the respective surface treatment and bonding procedure, each block was inserted in the other mold, 16 mm in height and 8 mm in diameter, leaving 8 mm space to be filled by the repairing composite, Gradia Direct Anterior (shade A1, GC; Tokyo, Japan). For a better assessment of the repair interface, different shade was selected for the repairing composite to discern from existing composite. The repairing composite was incrementally inserted and light-cured as previously described (Table 2).

3) Microtensile bond strength test

After a 24-h storage in 37℃ artificial saliva, each composite block was sectioned perpendicular to the bonded repair interface into 1-mm-thick slabs (n = 3 per block) with a low-speed diamond saw (Isomet 1000, Buehler Ltd., Lake Bluff, IL, USA) under constant water coolant. Each slab was trimmed along the repair interface to a modified hourglass shaped specimen using a fine diamond bur to concentrate the tensile load on repair interface (1 mm2 area of bonded surface). Five additional composite resin blocks were fabricated 16 mm in height and 8 mm in diameter to test the ultimate tensile strength (UTS).

Specimens were secured at the ends with cyanoacrylate adhesive (Zapit, Dental Ventures of America; Corona, CA, USA) to µTBS testing device. The test was conducted at a cross-head speed of 1 mm/min until failure. After failure, each repair interface area was measured and the bond strength value (MPa) was calculated.

3. Fracture toughness

Diagram of short-rod specimen is showed in Figure 1. Ten half specimens, like Figure 2b, were made for each group to conduct short-rod fracture toughness test using acrylic resin mold which is showed in Figure 2a. The surface was covered with slide glass and cured by light. Specimens had been stored in artificial saliva at 37℃ before the repair procedure was performed. Surface treatments and bonding procedures were the same as µTBS test. At each aging time, the half specimen was inserted into acrylic resin mold and covered with 45° beveled spacer (Figure 2c). After the mold was assembled as shown in Figures 2d and 2e, repairing resin was filled into the mold. Light curing was performed at both ends and from upper side for 40s. All specimens were separated from the mold (Figure 2f) and stored in artificial saliva. To compare with bulk fracture toughness of composite resin, additional 10 specimens were fabricated in bulk. After 24 hours, specimens were fixed to tensile testing jig by ligature wire. A tensile load was applied to each specimen at an extension rate of 0.5 mm/min until failure. The peak load at the time of specimen failure was obtained for each specimen and the fracture toughness values (KIC) was calculated with following equation.

Pc: maximum load until specimen is fractured

D: diameter w: length

Y*m: minimum stress intensity factor coefficient

Y*m = 28.10 + 58.99α0 - 122.3α0 2 + 183.3α03 (when W/D is 2.00)

α0: a0 / W a0: distance to chevron tip

4. Statistic analysis

The results of µTBS and interfacial KIC were analyzed by two-way ANOVA / Tukeys B test using SPSS 16.0 for window, with surface treatment and aging time as main factor (SPSS Inc., Chicago, IL, USA) (p < 0.05). Correlation analysis between µTBS and KIC was conducted.

5. Field emission scanning electron microscope (FE-SEM) examination

The representative specimens in each group were selected. The fractured specimens were mounted in aluminum stubs with carbon tape and sputter-coated with gold using Sputter-coating unit (SC 502 sputter coater, VG MICROTECH, England) and observed with a FE-SEM (Leo SUPRA 55, Carl Zeiss, Germany) at an acceleration voltage of 10 kV.

Results

1. Microtensile bond strength

Means and standard deviations for µTBS of all experimental groups are presented in Table 3. There was a significant difference between fresh resin groups and aged resin groups (p < 0.001). Among the fresh groups, group NF was similar to group SF and BF, while group NA was significantly different from group SA and BA among the aged groups (p < 0.05). Sand blasting had similar effect to bur roughening regardless of aging time. The interaction between the factors "surface treatment" and "aging time" was not significant.

2. Fracture toughness

Means and standard deviations for KIC are presented in Table 4. The statistical analysis showed that the surface treatment and aging time significantly affected composite to composite fracture toughness (p < 0.001), with no significant difference between sandblasting groups and diamond bur roughening groups. The interaction between the factors "surface treatment" and "aging time" was statistically significant (p = 0.001).

There was no correlation between fracture toughness and microtensile bond strength values.

3. FE-SEM

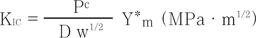

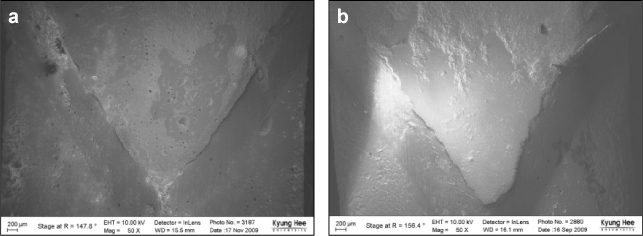

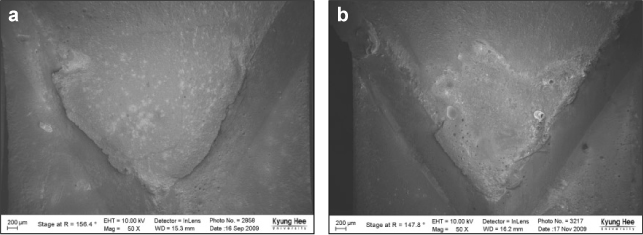

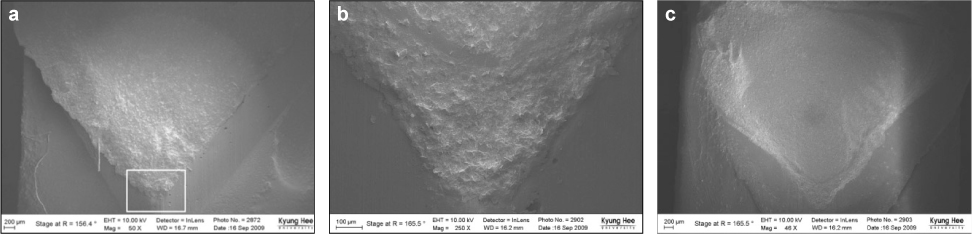

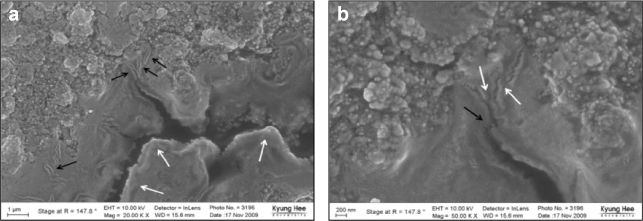

In FE-SEM results of none-treated groups (NF, NA) showed low KIC value, adhesive failures were prominent (Figure 3). Sandblasting and diamond bur roughening groups showed mixed failures having broad cohesive failure area (Figures 4 and 5). In these groups, images showed the stress concentrated on the notch tip, transferred along the bevel and ran into composite matrix through the weakest point existed around the bevel. There were laminations like scale around the notch which mean high resistance to fracture (Figure 5b). Figure 6 showed crack deflection and uncracked ligament bridging, which are crack shielding mechanisms. This phenomenon was not observed in specimen having low KIC value.

FE-SEM observation of none treated groups (×50). Mixed failure was prominent. The area of adhesive failures, dark gray area, was increased after 2weeks aging, (b). (a) Fracture surface of fresh resin. (b) Fracture surface of 2 weeks aged resin.

FE-SEM, Field emission scanning electron microscope.

FE-SEM observation of sandblasting groups (×50). (a) Fracture surface of fresh resin. The area of cohesive failure was prominent (upper: old composite, lower : new composite). (b) Fracture surface of 2 weeks aged resin.

FE-SEM, Field emission scanning electron microscope.

FE-SEM observation of diamond bur roughening groups (a, c: ×50, b: ×250). (a) Fracture surface of fresh resin showed almost cohesive failure. (b) Magnified image at chevron notch (white rectangle) in (a). There were laminations like scale around the notch which mean high resistance to fracture.(c) Fracture surface of 2 weeks aged resin. There was partial cohesive failure.

FE-SEM, Field emission scanning electron microscope.

FE-SEM observation of representative BF specimen. (a) There were crack deflection (white arrow) and microcracks (black arrow). They each are one of crack shielding mechanisms (×20,000). (b) Magnified image of (a). There were another crack shielding mechanisms, uncracked ligament bridgings (white arrow) and crack bridging (black arrow) (×50,000).

FE-SEM, Field emission scanning electron microscope.

Discussion

This study was designed to explain the fractural behavior on repaired composite according to different surface treatments and aging time. To avoid interference of other factors, bonding and repair materials were standardized. Since the newly added composite does not wet the etched composite surface, mechanically treated surfaces in all specimens were coated with a bonding agent. Two-step total etch, SB was selected as a bonding agent to reproduce the common clinical situation, where SB is widely used for convenience.

Newly added composite resin was also, Gradia Direct Anterior (GC; Tokyo, Japan), which has UDMA instead of Bis-GMA. UDMA is an aliphatic molecule which gives the polymer chain great mobility, thereby increasing the degree of conversion than Bis-GMA.19-21 The higher degree of conversion is, lesser chemical bonding between methacrylate radicals from old composite and repair composite is. For this reason, UDMA would clearly demonstrate the effect of micromechanical interlock by surface treatment rather than the effect of chemical bonding. That would provide useful information whether the effect of surface treatment surpassed the chemical bonding between resin-based materials or not for repair of old composite restoration.

Old composite can bond with new composite using free radicals in the oxygen inhibition layer or the remaining double bonds within polymerized composite if the oxygen inhibition layer has been removed. Although it has been shown that different monomers or monomer mixtures are responsible for determining the degree of conversion in dental composite materials, all the materials used as the repair substrates have a similar monomer composition.6 Degree of conversion of different Bis-GMA based composites ranged between 56% and 68%.22-24 Other study reported that 30% of C=C bonds remained unreacted during the copolymerization reaction.25 Aging process diminishes the amount of free radicals and remaining double bonds available and capable of reacting chemically with the new composite.4,26 The likelihood of achieving covalent bonding between resins appears to be negatively correlated to the age of the substrate resin.27

When a composite repair is required, the aging time of the old composite can be various. For example, a patient might return to the dental office with a fractured edge of the composite restoration or due to a partially unsatisfactory composite restoration. To simulate this immediate repair, fresh resin groups received rebonding procedure within 30 minutes. It has been assumed that the radical activity of monomer functional groups is the greatest in that time frame. On the other hand, the aged groups simulated the delayed repair condition where composite restoration had been functioning in the oral condition for a long time and there was no oxygen inhibited layer or free radicals available on the surface. There were few reports regarding to the remaining double bonds following aging time while some reported regarding to the intensity of the light, time of polymerization, monomer structure and solvent concentration.20,28-30 Previous studies on composite repair were conducted at various aging time since the composite block had been made, such as immediately,31 24 hours,1,5,32 9 days,3 1 week later32 and 2 weeks later.8 Aging condition was set up referring to similar literature storing in 37℃ artificial saliva for 2 weeks.3,8 Further studies are needed to suggest clear standards for the amount of remaining monomer or oxygen inhibition layer by aging time.

In the present study, µTBS of the experimental groups were inferior to UTS, and this finding was in agreement with the previous reports.3,5,9,33 Ferracane and Marker stated that this reduction mainly occurred from softening of the resin matrix, but the cracking within the resin and at the filler/matrix interface might have also contributed to the reduction.33 Other authors suggested that the effects of pH changes, salivary enzymes and the wet environment could have resulted in the degradation of composites' eluting components.3,9

µTBS of fresh groups ranged between 92% and 96% when compared to UTS, and that of the aged groups ranged between 72% and 85% (Table 3). The aged groups showed significantly lower bond strength than the fresh groups. It seems to be related to the difference of amount of available double bonds between the fresh and the aged composite surfaces as stated above. In addition, the polymerization of composite continued after light cure for 24 hours,34 and the diffusion rate of the propagating free radicals underwent a drastic reduction as the polymerization proceeded.29 That is, the fresh composites repaired within 30 minutes after the light cure have had more free radicals than the aged group have.

The surface treatment of aged resin composite was done to remove the superficial layer altered by the saliva exposing a clean, higher energy composite surface and increasing the surface area through creation of surface irregularities. Sandblasting simulated air abrasion in laboratory. Diamond bur roughening is an easy method to roughen the surface in the clinic if there is no microetcher. Different results have been reported for preparing composite surfaces using air abrasion and bur roughening.1,5,9,10 In the present study, the diamond bur roughening was as effective as sandblasting. µTBS of sandblasting and diamond bur roughening groups were significantly higher than that of untreated groups. Mechanical interlock between the old composite and the newly added composite seems to be more effective than chemical bonding. Futhermore, mechanical treatment increases surface wettablility.

Fracture toughness values of sandblasting and diamond bur roughening groups were also significantly higher than non-mechanically treated groups each aging time. It seems to be related to crack deflection (Figure 6a). Crack deflection is one of the crack shield mechanisms.35 Mechanical interlock by surface treatment acts as a filler which provides several toughening mechanisms including crack pinning36 and microcrack-induced toughening.37 It can deviate the interfacial plane which occurs crack propagation. Then, crack tip has more longer path, and linear energy required to fracture is increased.38 Futhermore, the energy to make rough fractured surface of composite is more than that of smooth fractured surface.

The concept of 'Craze' also can support the results of SA and BA different from NA group. Craze is the main mechanism of destruction under glass transition temperature. When tensile stress was added to polymer material on a vertical plane of stress direction, microvoids occur. Then, fibrils are orientated in direction of tensile axis and connect both ends of microvoid to make the net structure which controls the enlargement of the microvoids. This net structure which exists at the end of the crack is called craze.38 When there are additional stress concentrators such as defects or voids, the length of orientated fibrils becomes short, and they are easily disconnected at stress and progress to crack. Adhesive agent is weaker than composite resin and is easy to degrade due to hydrophilic monomers in wet environment. In addition, a defect by technical sensitivity is apt to be in the adhesive layer. Repaired surface without mechanical interlock cannot deviate the crack path and seems to be influenced more by defects in the adhesive layer. As a result, KIC of NA group showed the lowest value.

The interaction between surface treatment and aging time was statistically significant in fracture toughness (p < 0.001), while it was not significant in µTBS. For that reason, the KIC of fresh groups showed somewhat different pattern compared to the µTBS of them. It was diminished approximately 80% of bulk fracture toughness. It was not restored like bulk fracture toughness after fresh repair and remained relatively unchanged despite aging. These results were similar with previous studies.14,39

It has been proposed that an interfacial fracture mechanics approach which studies the failure of an interface by the initiation and growth of crack using a tool such as the fracture toughness test, would be more appropriate for testing relatively brittle material interface. Nevertheless, this fracture mechanics approach has not received much supports. Soderholm commented that it was so laborious and had time-consuming specimen preparation.39 It means this methodology no longer meets the basic requirements for an easy, fast, and 'first' product-screening test. For this reason, there have been many experiments that used bond strength instead. A correlation research between fracture toughness and bond strength, however, is needed to use the bond strength data for a study on fractural behavior.

Unfortunately, there have been only few studies on the correlation between fracture toughness and tensile strength of composite-composite repair interface. In a case of dentin-composite interface, many studies reported there was no significant correlation even though they had a similar pattern.13,15,39 Dhuru and Lloyd have mentioned that the fracture stress of the repair may be a function of both the interfacial strength and defect produced by the operators' repair technique.14 This means composite to composite interface may influence on the fracture toughness test differently from dentin to composite interface due to the matrix discrepancy. Studies on fracture toughness of dentin to composite interface have a limitation to serve as a reference.

In the present study, there was no correlation between fracture toughness and microtensile bond strength values. It seems to be difficult to correlate under the same criteria. First, it is impossible to get same specimen for microtensile bond strength test and fracture toughness test. Second, the difference between µTBS and KIC is thought to be an innate dissimilarity of the test methods. They have different failure mechanisms. The main reason for Fracture mechanics fails more often in the adhesive region, while cohesive failure in the adherend is more common among strength tested specimens.15,39 Fracture of tensile bond strength specimens began from some point around the circumference, coincident with the position of stress concentration, and propagated toward the center. On the other hand, the load in short-rod fracture toughness specimen concentrated at the chevron notch. Chevron notch initiates and helps maintain crack propagation along the midplane of the specimen, where the bonded interface is located. The fracture toughness test could be more appropriate for testing repaired composite interface.

Specimens of the fracture toughness test showed the fracture mechanism in Fe-SEM observation. Most specimens of non-mechanically treated groups showed adhesive failure along the interface making smooth surface, while those of mechanically treated groups showed mixed failures in which cohesive failures were dominant making rough surface (Figures 3 and 5). Rough surface has higher KIC than smooth surface. It means more energy is required to fracture the interface as shown in Table 4. The crack propagated through composite as well as adhesive layer demonstrating toughening mechanism of the material where the difference of toughness was arisen from (Figure 6). For instance, crack bridging, the most common form of crack-tip shielding, occurred where the dominant crack links with microcracks ahead of the crack tip (Figure 6b). The microcracks provide a mechanism for the formation of uncracked ligament bridges and can act to shield the crack tip toughening the material extrinsically.36,40 These crack shielding mechanisms appeared in specimens having high KIC. In other words, fracture toughness test can explain fractural behavior for repaired composite interface. It cannot be substituted by bond strength test.

To date, the study on fracture toughness of composite to composite repair interface has been scare. The present study evaluated the effect of surface treatment and aging time on composite repair by a practical test method, fracture toughness. This provides significant data that can be used for a practical prediction of fractural resistance in the repaired composite restorations. However, there is a limitation in that there are many variables yet to be tested including the age at which the repair is made, the interval between fracture and repair, the aging condition, and so on. More researches using fracture toughness are necessary for the evaluation of fractural behavior of the repaired composite.

Conclusions

Repair of fractured composite can be conducted effectively by means of appropriate surface treatment. For the reliable evaluation of fractural behavior of the repaired composite, both µTBS test and fracture toughness test were carried out. Within the limitations of the present study, the fresh composite resin showed higher µTBS than the aged composite resin did (p < 0.01). Comparing to µTBS of mechanically treated groups, µTBS of non-mechanically treated group was similar in the fresh resin groups, while significantly lower in the aged resin (p < 0.05). The fracture toughness values of mechanically treated groups were higher than that of non-mechanically treated group no matter whether it was sandblasting or bur roughening (p < 0.05). Surface treatment and aging time had a significant influence on the interfacial fracture toughness (p < 0.001). There was no correlation between fracture toughness and microtensile bond strength values. Specimens having high KIC showed toughening mechanism including crack deviation, microcracks and crack bridging.

In conclusion, mechanical surface treatment seems to be an important factor for the effective composite repair and the fracture toughness test could be used as an appropriate tool to examine the fractural behavior of the repaired composite with microtensile bond strength.