Effects of 3 different light-curing units on the physico-mechanical properties of bleach-shade resin composites

Article information

Abstract

Objectives

This study investigated the microhardness, flexural strength, and color stability of bleach-shade resin composites cured with 3 different light-curing units.

Materials and Methods

In this in vitro experimental study, 270 samples were fabricated of bleach and A2 shades of 3 commercial resin composites (Point 4, G-aenial Anterior, and Estelite Sigma Quick). Samples (n = 5 for each trial) were cured with Bluephase N, Woodpecker LED.D, and Optilux 501 units and underwent Vickers microhardness and flexural strength tests. The samples were tested after 24 hours of storage in distilled water. Color was assessed using a spectrophotometer immediately after preparation and 24 hours after curing. Data were analyzed using 3-way analysis of variance and the Tukey test (p ≤ 0.001).

Results

Samples cured with Optilux exhibited the highest and those cured with LED.D exhibited the lowest microhardness (p = 0.023). The bleach shade of Point 4 composite cured with Optilux displayed the highest flexural strength, while the same composite and shade cured with Sigma Quick exhibited the lowest (p ≤ 0.001). The color change after 24 hours was greatest for the bleach shade of G-aenial cured with Bluephase N and least for the A2 shade of Sigma Quick cured with Optilux (p ≤ 0.001).

Conclusions

Light curing with polywave light-emitting diode (LED) yielded results between or statistically similar to those of quartz-tungsten-halogen and monowave LED in the microhardness and flexural strength of both A2 and bleach shades of resin composites. However, the brands of light-curing devices showed significant differences in color stability.

INTRODUCTION

Dental clinicians have long sought light-curing units (LCUs) with increased efficacy for curing resin composite [1]. Quartz-tungsten-halogen (QTH) LCUs have been the established gold standard for this purpose. However, following the advent of light-emitting diode (LED) LCUs, which have multiple benefits, QTH LCUs have been largely replaced with LEDs [23].

Composite polymerization can be initiated by an α-cleavage process, as observed with type I photoinitiators, and/or H-abstraction, as with type II initiators [4]. Camphorquinone, a type II photoinitiator commonly found in resin composites, has a spectral sensitivity of 420 nm to 480 nm and is cured by conventional LED [2]. However, a major drawback of camphorquinone is its yellow color, which hinders its application in bleach-shade resin composites. Additionally, its initiation is generally slower than the photoinitiation caused by type I photoinitiators [56]. Type II photoinitiators tend to be more useful than type I initiators due to better optical absorption of wavelengths in the near-visible region [7].

The use of bleach-shade resin composites has become very popular. Thus, a new generation of photoinitiators (e.g., Lucirin [2,4,6-trimethylbenzoyldiphenylphosphine oxide [TPO]), phenyl bis-phosphine oxide, and phenyl propanedione) has been introduced to improve the color in these bleach-shade resin composites [8]. These type I photoinitiators require relatively low radiant exposure for activation. The absorption peak of a type I photoinitiator is near the ultraviolet region and extends slightly into the visible region. Due to greater molar absorptivity, type I photoinitiators promote effective curing. Furthermore, the low pigmentation of type I initiators may advance color matching since their absorbed wavelength is relatively short [910]. Moreover, type I photoinitiators do not require co-initiators [4]. The compound 1-phenyl-1,2 propanedione (PPD), which uses both methods of polymerization, is considered to be a photosensitizer that forms free radicals through the transfer of protons from an amine co-initiator as well as via cleavage. Thus, PPD can be applied individually or with tertiary amines as co-initiators [11]. However, type I initiators have been reported to have comparably low spectral sensitivity (380–420 nm), which may be incompatible with the commonly used monowave LCUs [12]. To overcome this problem, new LCUs offering a wider range of wavelengths, termed polywave LCUs, have been introduced to the market.

The literature is rich in studies regarding the effects of LCUs on the mechanical and physical properties of resin composites [2131415]. Some authors have stated that LED devices are comparable or even superior to QTH LCUs in optimizing the mechanical properties of the composite [1315]. However, others have argued that QTH devices are still superior to LED LCUs [1214]. No difference has been reported regarding the color stability of composites cured with QTH and LED LCUs [1617]. However, no consensus has been reached regarding the color stability of composites containing type I photoinitiators relative to those that contain type II photoinitiators, such as camphorquinone [5811181920]. Moreover, some researchers have argued that polywave LED LCUs are more compatible with bleach-shade composites than with monowave LCUs, while others have stated that polywave LCUs are unsuitable for the efficient curing of composites containing a non-type I photoinitiator (e.g., camphorquinone) [122122232425]. Others have found no significant difference between monowave and polywave LCUs in this respect [26].

The aim of the present study was to assess and compare the effects of 3 LCUs (Bluephase N [polywave LED; Ivoclar Vivadent, Schaan, Liechtenstein], Woodpecker LED.D [monowave LED; IDS DenMed Pvt. Ltd., New Delhi, India], and Optilux 501 [QTH; Kerr Corporation, Orange, CA, USA]) on the physico-mechanical properties of bleach-shade and A2 resin composites. The null hypothesis was that the LCUs would not differ in their impacts on the physico-mechanical properties of bleach-shade composites.

MATERIALS AND METHODS

This in vitro experimental study was performed on bleach and A2 shades of 3 commercially available resin composites: Point 4, G-aenial Anterior, and Estelite Sigma Quick. The study was approved by the ethics committee of the School of Dentistry of Shahid Beheshti University of Medical Sciences (IR.SBMU.RIDS.REC.1396.473). Table 1 presents the characteristics of the resin composites used in this study. The characteristics of the 3 LCUs used in this study are presented in Table 2.

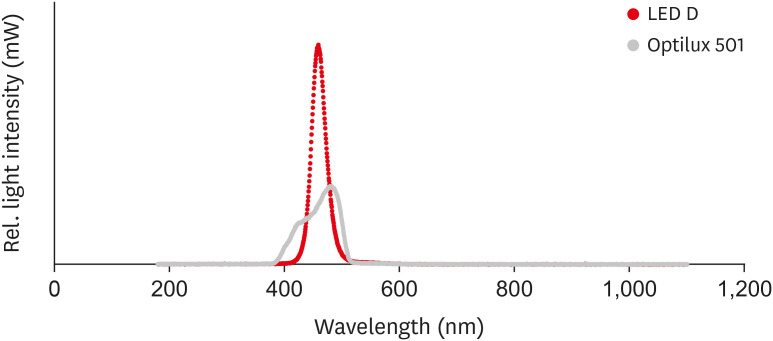

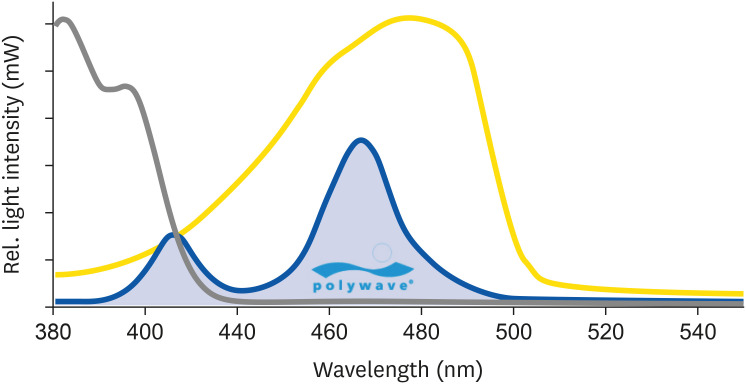

The spectral radiant power values (mW/nm) of the Woodpecker LED.D and Optilux 501 devices were not available in the brochures provided by the manufacturers, while the manufacturer provided this information for the Bluephase N unit. Thus, spectral emission analyses were performed for the Woodpecker LED.D and Optilux 501 LCUs using a spectrophotometer (AvaLight DH-S; Avantes, Apeldoorn, The Netherlands) attached to an integrating sphere (AvaSpec 2048 Tech; Avantes). After adjusting the tip of the LCU to a specific distance from the fiber-optic tip of the spectrophotometer, analyses were performed using the device, and the data required for graphs were obtained using the software (Figure 1). Figure 2 shows the curve for Bluephase N provided by the manufacturer [27].

Spectral radiant power (mW/nm) of LED.D and Optilux 501 devices.

Rel., relative; LED, light-emitting diode.

Spectral radiant power (mW/nm) of Bluephase N (blue line) compared with the absorption spectra of camphorquinone (yellow) and TPO (gray).

Rel., relative; TPO, 2,4,6-trimethylbenzoyldiphenylphosphine oxide.

Microhardness

Ninety disc-shaped specimens measuring 8 × 2 mm were fabricated from the 3 resin composites using stainless steel molds (n = 5 for each group). The molds were rested on a Mylar strip, and light curing was performed through a glass slide positioned on the top of the mold for 20 seconds at 5 areas (12-, 3-, 6-, and 9-o’clock and at the center) using the overlapping technique as described in ISO 4049-2009 [528]. The samples were coded at the bottom using the sharp tip of a scalpel. The surfaces of the samples were then polished by 1 operator applying a constant force with 1500-, 2000-, 2500-, and 3000-grit waterproof silicon carbide papers (Matador; Starcke GmbH & Co. KG, Melle, Germany) followed by a felt disk (Diamond, FGM Dental Group, Joinville, Brazil) on a low-speed handpiece. The samples were stored in distilled water at 37°C for 24 hours and were then transferred to a Vickers hardness tester (Zwick/Roell GmbH, Ulm, Germany). Microhardness was measured at 3 points by applying a 200-N load for 10 seconds. The mean of the 3 values was calculated and reported as the microhardness of the respective sample.

Flexural strength

A total of 90 bar-shaped samples measuring 25 × 2 × 2 mm were fabricated from the 3 resin composites using a stainless steel mold (n = 5 for each group). The samples were stored in distilled water at 37°C for 24 hours. They were then dried and transferred to a universal testing machine (Z020; Zwick/Roell) for a 3-point bending test. The samples were subjected to a load at a crosshead speed of 0.5 mm/minute until fracture. The flexural strength was calculated using the following formula:

where F is the maximum fracture-causing load, L is the distance between the 2 pivots (25 mm), b is the sample width, and d is the sample thickness [29].

Color stability

Ninety disc-shaped samples measuring 8 × 2 mm were fabricated from the resin composites as explained for the microhardness test (n = 5 for each group). The sample color was then measured immediately after curing using a spectrophotometer (Ci64; X-Rite, Grand Rapids, MI, USA) according to the L*a*b* system of the International Commission on Illumination (Commission International de l’Eclairage; CIE). Color was assessed under standard D65 light at a 12° angle against a gray background (Checker Passport; X-Rite). The 4-mm diaphragm of the device was adjusted at the center of each sample, and the primary values of L*a*b* color parameters were recorded. The samples were stored in distilled water at 37°C, and color was assessed after 24 hours. To assess the color change during the 24-hour period, Color iMatch 9.5.10 software (X-Rite) and the following formula were used [10]: ΔE = Δa*2 + Δb*2 + ΔL*2.

Statistical analysis

Data were analyzed using SPSS version 18 (SPSS Inc., Chicago, IL, USA). A normal distribution of data was confirmed using the Kolmogorov-Smirnov test. Statistical analyses were carried out using 3-way analysis of variance (ANOVA) followed by the Tukey honestly significant difference test for pairwise comparisons. p values of less than 0.05 were considered to indicate statistical significance.

RESULTS

Microhardness

Table 3 shows the mean microhardness levels and standard deviations of the bleach and A2 shades of the resin composites cured with different LCUs. Three-way ANOVA revealed statistically significant differences regarding the effects of i) type of resin composite (p ≤ 0.001), ii) shade of resin composite (p = 0.001), and iii) type of LCU used (p = 0.017) on microhardness. Regarding the LCU used, monowave LED was associated with the lowest and QTH with the highest microhardness in the composite samples, and the difference between these was statistically significant (p = 0.023). However, polywave LED did not significantly differ from either monowave LED (p = 0.054) or QTH (p = 0.936) in the microhardness of resin composite samples.

Flexural strength

The mean flexural strength values of the A2 and bleach shades of the resin composites cured with different LCUs are shown in Table 3. Three-way ANOVA showed a statistically significant difference in the flexural strength levels of the composites (p < 0.001), with G-aenial having the lowest and Point 4 having the highest flexural strength (p < 0.001). The 2- and 3-level interactions were significant (p < 0.001). Additionally, 2-way ANOVA showed no significant difference in the flexural strength of the bleach and A2 shades of G-aenial (p = 0.188). However, LCU choice had a significant effect on flexural strength for the G-aenial samples, with QTH yielding the lowest and monowave LED the highest strength (p < 0.001). Accordingly, polywave LED was associated with a higher flexural strength than QTH and a lower strength than monowave LED (p < 0.001). The A2 shade of Sigma Quick displayed a higher flexural strength than the bleach shade (p < 0.001). Furthermore, the type of LCU utilized had a significant effect on the flexural strength in these samples as well (p < 0.001); monowave LED was associated with the highest flexural strength and differed significantly from polywave LED and QTH (p < 0.001). However, the difference between polywave LED and QTH was not significant with respect to flexural strength (p = 0.999) in the Sigma Quick samples.

For Point 4 composite, the A2 and bleach shades did not significantly differ in flexural strength after curing with either monowave or polywave LED (p = 0.102 and p = 0.091, respectively). However, the bleach shade of Point 4 exhibited higher flexural strength than the A2 shade in samples cured with QTH (p < 0.001). The bleach shade of Point 4 cured with monowave LED yielded lower flexural strength than the same shade cured with QTH (p = 0.003), Nonetheless, the flexural strength level of Point 4 composite cured with polywave LED fell between those of monowave LED and QTH and did not significantly differ from either. With the A2 shade, however, QTH use was associated with significantly lower flexural strength than monowave LED (p = 0.005). Polywave LED fell between QTH and monowave LED with respect to flexural strength and significantly differed from both (p = 0.09 and p = 0.025, respectively).

Color change

Table 3 displays the ΔE values of the resin composites. Three-way ANOVA revealed a statistically significant difference in ΔE among the composites (p < 0.001). Point 4 and Sigma Quick exhibited statistically similar color changes (p = 0.055), but both ΔE values were significantly lower than the color change of G-aenial (p < 0.001). Given the significant difference in level 2 and level 3 interactions, a subgroup analysis was performed for each resin composite. For the bleach shade of Point 4, LCU choice significantly impacted the resulting color change; while the ΔE values associated with QTH and monowave LED were statistically similar (p = 0.859), the polywave LED device was associated with a significantly higher ΔE than either of the other 2 LCUs (p < 0.001). However, no significant difference based on LCU choice was observed in the color change of the A2 shade of Point 4 (p = 0.114). The bleach shade had a higher ΔE than the A2 shade in the polywave LED group; however, the reverse was true in the QTH group (p < 0.002).

With the G-aenial composite, the A2 and bleach shades showed no significant difference in color change (p = 0.259), although the type of LCU significantly impacted ΔE. Polywave LED was associated with the greatest color change, with a statistically significant difference from both QTH and monowave LED (p < 0.001). QTH and monowave LED were not significantly different from each other (p = 0.997).

For the Sigma Quick composite, the type of LCU and the shade showed statistically significant differences with respect to ΔE. The bleach shade exhibited the lowest ΔE after QTH curing, followed by curing with monowave LED. The highest ΔE was recorded in samples cured with monowave LED. Statistically significant differences were present between all of the groups (p < 0.05). For the A2 shade, QTH and polywave LED did not differ significantly from each other (p = 0.369). However, monowave LED yielded a significantly higher ΔE than the other 2 LCUs (p < 0.05). In contrast, the comparison of ΔE in different shades within each LCU revealed that in samples cured with monowave LED, the bleach shade exhibited a higher ΔE than the A2 shade (p = 0.01), while no significant difference was noted between the 2 shades in samples cured with polywave LED and QTH (p > 0.05).

DISCUSSION

In this study, we assessed the microhardness, flexural strength, and color change of bleach-shade resin composites cured with 3 different LCUs. The curing of resin composites with different LCUs resulted in variable microhardness, flexural strength, and color change. In our study, the highest microhardness was noted in Point 4 and the lowest in G-aenial composite samples. The microhardness of resin composites after polymerization depends on factors such as the types of filler, matrix, photoinitiator, and LCU, as well as the intensity and wavelength of light [2]. Despite the different percentages of fillers in Point 4 and G-aenial composite (76%) and Sigma Quick (82%), the results did not directly relate to the amount of filler loading. The findings may instead be due to differences in the resin matrix and size of filler particles.

In all 3 tested composites, QTH yielded the highest and monowave LED yielded the lowest microhardness values. The results of previous studies on this topic are controversial. Gomes et al. [1] reported that the microhardness values of bleach-shade composites cured with a QTH LCU with a light intensity of 728 mW/cm2 were equal or greater than those of composites cured with a LED LCU with a light intensity of 1,220 mW/cm2. These were higher than the microhardness values of the group cured with a lower-intensity LED curing light. The researchers attributed these findings to the power intensity of the devices. Franco et al. [14] emphasized the role of power density and reported that higher microhardness values in samples cured with a QTH LCU were due to the heat generated by the tip of the device, which increases the mobility of molecules and subsequently increases the polymerization rate. Their findings aligned with ours. However, since the microhardness values of samples cured with a polywave LED with an intensity of 650 mW/cm2 fell between those yielded by monowave LED (800 mW/cm2) and QTH (850 mW/cm2) LCUs, it may be concluded that the greater wavelength compatibility of polywave LED relative to monowave LED was responsible for the outcome [21530]. Nevertheless, various results have been reported for different composites cured with various LCUs, and thus, this controversy has been attributed to differences in the type of initiators. Moreover, it has been shown that LCUs with similar energy densities do not necessarily yield similar microhardness values [230].

Conte et al. [31] evaluated the surface microhardness of Lucirin-TPO–containing resin-based composite cured with 3 LED LCUs at 2 different energy densities. They stated that a higher energy density was associated with better results than a lower energy density. Multi-peak LED curing was associated with a higher Vickers hardness than single-peak LED when curing a TPO-containing composite. This conclusion aligned with the current study regarding the efficiency of both single-peak and multi-peak LEDs in achieving comparable microhardness values, even though the energy density of the single-peak LED in the current study was lower than that of the multi-peak LED used.

Regarding flexural strength, Point 4 exhibited the highest and G-aenial the lowest strength. The difference among the 3 composites in this respect was statistically significant. Filler percentage, type of filler, type of resin matrix, and properties of the LCU all affect the flexural strength.

In the current study, higher flexural strength was noted in the monowave LED group for all composites except for the bleach shade of Point 4. This was followed by the polywave group. Stahl et al. [32] evaluated the flexural strength and polymerization potential of composites cured with LED and QTH LCUs and, although the light intensity of the QTH device was twice that of the LED, no difference was noted in flexural strength and polymerization potential between the 2 devices. The researchers explained this as due to the higher compatibility in wavelength of the LED device with the photoinitiator (mainly camphorquinone). In the current study, monowave and polywave LED had intensity levels close to that of the QTH device. Thus, higher flexural strength than QTH in these 2 groups was expected for most resin composites.

Based on the results of this study, it can be concluded that, relative to the other composites, the bleach shade of Point 4 contains a photoinitiator that is better compatible with QTH and polywave LED. In bleach-shade Point 4 composite, the results of monowave LED were not significantly different from those of polywave LED. According to Miletic and Santini [23], despite the higher compatibility of polywave LCUs with composites containing initiators other than camphorquinone, monowave LED may also show optimal performance given that its wavelength does not differ significantly from the peak absorbance of the photoinitiator. This result is due to the high intensity of light and high photon production by such devices. The same result was expected with the bleach shade of other composites; however, different manufacturers have unique formulations for their products that may yield different results.

Massotti et al. [33] analyzed the flexural strength of resin composites cured with monowave and polywave LED LCUs and showed that the flexural strength of samples cured with polywave LED was higher. This finding contrasted with our result. However, it should be noted that the Massotti et al. [33] study involved using the polywave LED in high-intensity mode, which has about twice the irradiance of the monowave LED. In our study, the intensity of the polywave LED (650 mW/cm2) was slightly less than that of the monowave LED (650–800 mW/cm2).

Polymerization quality can affect the color stability of resin composites. Thus, LCUs play an important role in this respect. In the current study, color was assessed immediately and at 24 hours after curing and reported as a color difference (ΔE). Common consensus posits that ΔE < 1 is not perceivable by the human eye; values between 1-3.3 are clinically acceptable, and ΔE > 3.3 is clinically unacceptable [5]. In our study, the mean ΔE values of Point 4 and Sigma Quick were lower than that of G-aenial, but the results were highly variable in different subgroups. In general, the results showed that in all groups except for the bleach shade of Sigma Quick, the results associated with QTH and monowave LED were similar. This finding was in agreement with that of Domingos et al. [16], who attributed the finding to the high intensity of light in LED devices and the narrow spectrum of wavelength compatible with the photoinitiator.

Among the LCU devices, polywave LED was associated with the highest ΔE in the bleach shade of Point 4, both shades of G-aenial, and the A2 shade of Sigma Quick. A lower ΔE of both shades of Point 4 composite after curing with monowave LED aligned with the results reported by Sabatini et al. [34], who showed that Point 4 had a high ΔE immediately after curing that remained stable for 24 hours. In that study, the researchers cured the samples using a Bluephase 16i (Ivoclar/Vivadent) monowave device. The reason for the high ΔE values of composites cured with polywave devices has yet to be determined.

de Almeida Souza et al. [35] reported no statistically significant difference in microhardness and ΔE between the 2 generations of LEDs. In contrast, they observed a statistical difference between the two LEDs for 2 of the composites containing different photoinitiators. Those researchers concluded that the composition of resin composites appeared to have more influence on analyses than the type of LED. Although the composite brands and shade selected differed from the current study, the overall conclusion aligned with our findings.

CONCLUSIONS

Within the limitations of this study, a polywave LED LCU yielded results in between or similar to those of QTH and monowave LED in the microhardness and flexural strength of both A2 and bleach-shade resin composites. However, color stability differed depending on the commercial light-curing device used.

Notes

Conflict of Interest: No potential conflict of interest relevant to this article was reported.

Author Contributions:

Conceptualization: Torabzadeh H, Farzad A, Panahandeh N.

Investigation: Farzad A, Haghi S, Masoumbeigi M.

Methodology: Kasraei S, Torabzadeh H, Farzad A.

Supervision: Panahandeh N.

Writing - original draft: Panahandeh N.

Writing - review & editing: Kasraei S, Torabzadeh H.